We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

New recycling machine now in 3D!

The versatile plastic recycling machine is ideal for recycling PE/PP films and bags, pre-crushed PP raffia, rigid regrinds, and more. Its flexibility and efficiency have helped thousands of producers obtain high-quality recycled pellets in a simple and easy way.

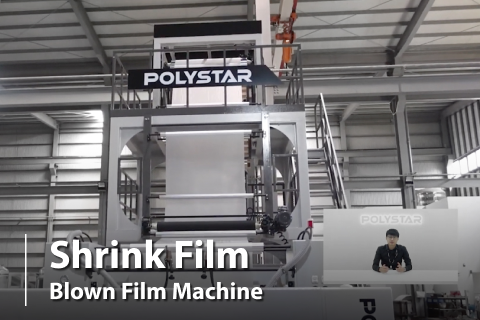

How to Produce a Good Quality LDPE Shrink Film?

LDPE Shrink Film has a low melting point and great durability, making it particularly useful for wrapping your final products, such as water bottles and food products.

Plastpol 2017

With more than 15 worldwide exhibitions in 2017 along with other exciting opportunities, the plastic recycling machine supplier is developing a broader range of advanced yet simple recycling solutions to meet the demands of different industries.

Meet POLYSTAR in Exhibitions

POLYSTAR participates in all major exhibitions worldwide, meet POLYSTAR in exhibitions and see POLYSTAR plastic recycling machines and blown film machines with live demonstrations!

Industry4.0 - Online Spare Parts Service

POLYSTAR makes sure that all of its distributors are equally service-oriented with skilled engineering teams that provide installation, after sales services, and maintenance in their markets. POLYSTAR provides services worldwide to all economic sectors including packaging, plastic production, recycling, environmental, construction, agricultural, and governmental sectors.

K 2016

At K Show 2016, POLYSTAR presented its latest recycling machine model Repro-Flex, which is extremely easy to operate, perform maintenance and work with different types of post-industrial material.

Taipeiplas 2016

POLYSTAR has been actively expanding the global market in the past two years. Through active business marketing promotion and joint efforts with global agents, it demonstrated a strong international brand image and strength at the Taipeiplas 2016 exhibition.

NPE 2015

In March 2015, POLYSTAR showcased its latest film recycling technology in Orlando USA. The re-engineered cutter-compactor recycling line was first introduced in K show 2013 and has been demonstrated throughout important exhibitions worldwide.

PP Raffia Recycling Machine

The integration of a heavy-duty single-shaft shredder, it offers high efficiency in reducing the size and the strong structure of PP raffia, woven bags, sacks and so on.

Arabplast 2015

The future is "now" for Polystar after Arabplast Dubai 2015 exhibition. With the upcoming NPE (Orlando) in March 2015, POLYSTAR will be showing a newly developed plastic recycling machine. Furthermore, a new testing facility, planned to open in 2015, will test runs along with the completion on PE PP film recycling machine.

Taipeiplas 2014

POLYSTAR will be showing its new model "Repro-Flex" in Taipei Plas this September. The re-engineered system is designed specifically for processing packaging film waste of PE, PP (BOPP)

About POLYSTAR

POLYSTAR is a leading plastic machine manufacturer in Taiwan. We specialize in the production of plastic recycling machines and blown film extrusion machines.

Producing films with recycled pellets

POLYSTAR's blown film lines are capable of processing various material types including virgin resins, recycled and biodegradable materials, and CaCO3. Many producers replace their old equipments with ABA blown film machines for its flexibility of integrating with more recycled materials.

AB Two Layer Co-extrusion

The two extruders are capable of loading two kinds of materials, composing each A and B layer. That means we could use different materials or even different colors in each extruder.

Multilayer Film Recycling Machine

Repro-Flex Plus Two-stage Plastic Recycling machine is specially designed for reprocessing printed PE and PP flexible packaging material with heavily-printed surface and water content.