We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Strand Type Pelletizing Machine for PP Plastic Waste

For reprocessing the PP/PS plastic waste, using the plastic pelletizing machine with strand pelletizers is the most suitable way with its effective, and simple operation!

Plastic Rigid Regrind Recycling Machine for PE, PP, ABS, PS

The screw conveyor in the plastic pelletizing system feed the plastic material automatically (such as HDPE milk bottle flakes or PE/PP pipes), without manual feeding can save labor costs. In the water-ring pelletizing system (hot die face pelletizing), the plastic waste is melted by the extruder and then directly cut by the rotating knives attached to the surface of the water-ring die head.

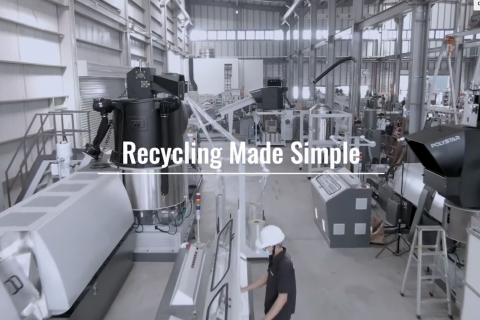

We Provide Recycling Solutions - POLYSTAR

POLYSTAR is a leading plastic machinery from Taiwan. We specialize in the production of plastic recycling machines and blown film extrusion machines.

How to Choose the Right Recycling Machine? | Single-stage & Two-stage Recycling Machines

Repro-Flex and Repro-Flex Plus are both cutter-compactor integrated recycling machines. This system eliminates the necessity of pre-cutting the material, since the cutter-compactor pre-cuts, pre-heats, and mixes the material that will be fed directly into the extruder.

Plastic Recycling Machine for Post-Consumer Waste in Demand

Several recyclers in Australia, India, Saudi Arabia, Colombia, and the US have repeated their orders with multiple higher-capacity plastic recycling machines to be able to comply with the increasing recycling demands of PE wash films and bottle waste.

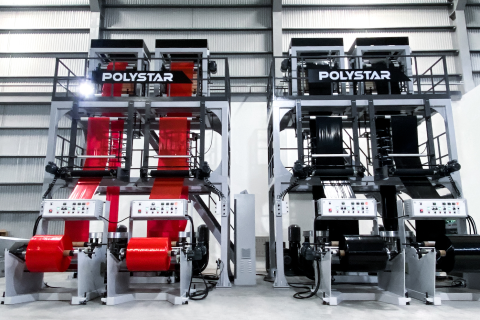

2 Color Stripes Blown Film Machine

Co-extruders that produce films with two stripes of different colors are equipped with two extruders allowing you to use two colors. In addition, if the die head is changed, it is capable of producing a 2-layer plastic film. Thus, a single machine will give you a variety of products.

Double Head Blown Film Machine for PE Films - Increase your production

The twin-head design enables producers to produce two separate tubular films with one extruder, increasing the efficiency for producing films in small widths.

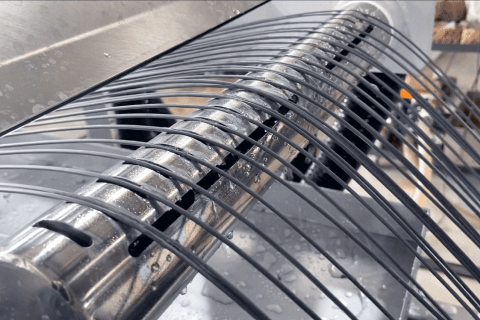

Air Cooled PE film recycling machines for PE producers

Air cooled mini plastic recycling machine is designed for recycling PE film and bag scraps, film-on-rolls, or T-shirt bag cut-offs from in-house production lines. Lightly-printed films can also be recycled into high-quality, uniform pellets.

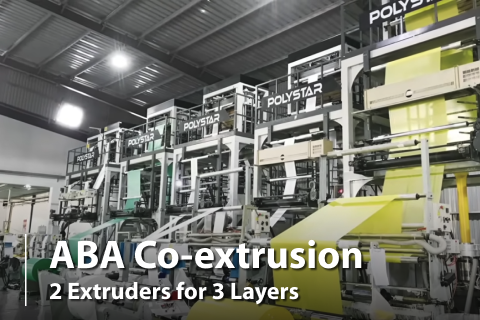

How to produce a stronger film with a lower cost? | ABA Blown Film Machine

ABA Co-extrusion blown film machine has its advantages over one layer blown film machine for certain applications like garbage bags, shopping bags, and T-Bags that are higher in thickness or require more film strength.

【Factory Tour in house live】Clip - STAR - X Blown Film Machine

The POLYSTAR's live session will only take you 15 minutes to learn the highlights and innovative technologies of our High-speed Blown Film Machine.

Two-stage recycling machine | Repro-Flex Plus

Repro-Flex Plus is able to reprocess the highly printed material and improve the quality and the productivity of the recycled pellets. Two filtration and three degassing steps ensure the minimal degradation of the material, which produces uniform pellets for reprocessing directly into your production line.

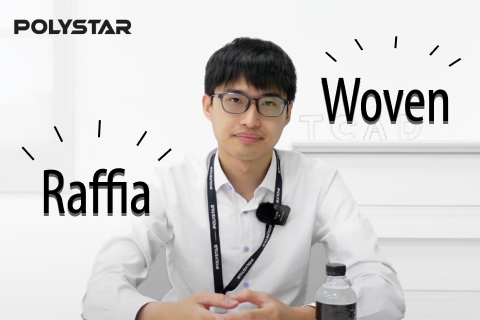

How to Recycle Raffia in One-Step with a Shredder Recycling Machine? | Repro-One from POLYSTAR

Post-industrial recycling of PP raffia, woven sacks, tapes, and non-woven bags could be challenging. Some producers struggle with their own waste since these materials are difficult to re-process with one recycling machine.

Moving to new manufacturing and testing center in 2019

Taiwanese recycling equipment and blow film extrusion machine maker Polystar Machinery Co. Ltd. is spending $9 million to build a new factory that will increase its capacity and upgrade its showroom and testing center.

Film. Raffia. Regrind - World’s Simplest Recycling machine

POLYSTAR designs machines to be simple and focus on what’s most important to plastic producers who are looking for an easy and stable operation.

Over 10,000- Subscribers on Youtube Channel

POLYSTAR has installed over 4,900 machines in 110 countries since 1988 and continues to focus on user-friendliness of its machines through re-engineering, making recycling extremely “Simple” – Easy operation and maintenance is what makes POLYSTAR the No.1 Recycling machine producer today.