We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Vietnam - PE Bag Producer Maximizes In-house Recycling Efficiency

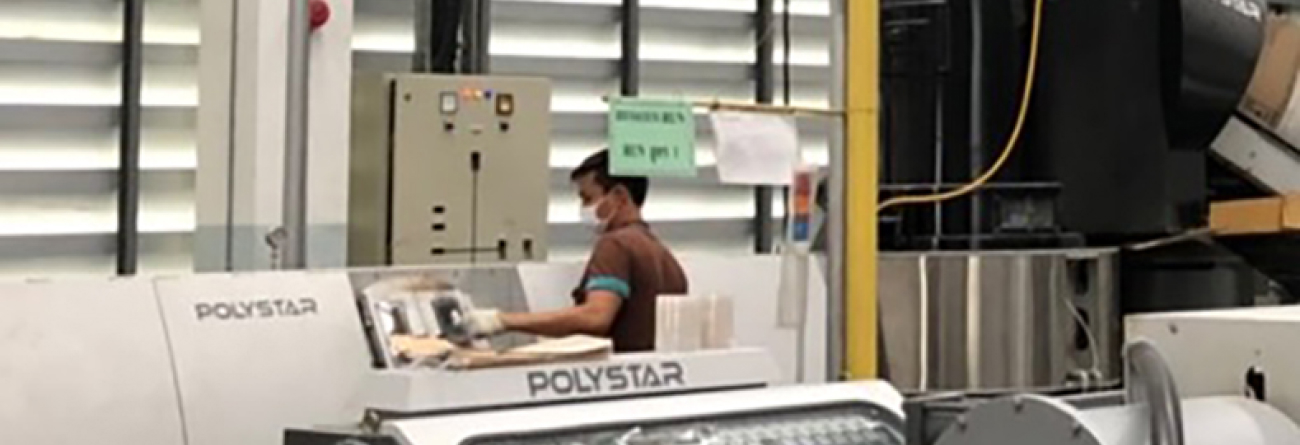

Since the installation of the POLYSTAR HNT-120V in Hanoi last September, the 400-500 kg/hr recycling machine has never stopped working for the Hanoi-based film producer who manufactures a wide range of products including HDPE, LDPE/LLDPE, OPP, CPP, BOPP bags as well as stretch film and metallized film. The machine has been running 24/7 non-stop except for routine maintenance once every two weeks.

With a monthly production of 1,700 tons, the PE/PP bag producer is amongst the largest and finest bag producers in Vietnam, and exports more than 95% of its products to Japan and Europe.

operate that it runs like an automatic robot, our operators love to work with this machine."

Mr. Nguyen, Managing Director of the ISO-9001 certified Vietnamese company with hundreds of staff

For Mr. Nguyen, what’s more impressive is that the company is now able to use a higher percentage of recycled pellets back to their Italian-made blown film machines without affecting the film quality. Compared to the recycling machines that the company had previously worked with:

"The pellets might look similar from the outside, but the quality is actually very different. This really lowers our production cost by a significant margin."

Mr. Nguyen, Managing Director explained

__23L04aZoNC.png)

With the new factory expansion which aims to increase another 30~40% of its current production, the company has already planned space to bring in the second POLYSTAR HNT-120V to effectively process all of its in-house waste material.