We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Success in Rosupack

A-B-A machines are very popular nowadays largely because a high percentage of CaCO3 compound can be used in the B (middle) layer of the film. This significantly reduces production costs thanks to the large use of calcium carbonate and recycled material.

Since 2011, POYSTAR has brought focus to the manufacturing of ABA film lines. Approximately 120 machines have been installed worldwide. POLYSTAR has already installed 6 sets of ABA machines in Russia in 2014 and the trend of Russian film producers to acquire ABA machines is likely to increase by a large margin this year.

Mono-Layer Film Production Becomes More Competitive

POLYSTAR has introduced the ABA technology in various markets, particularly in countries where mono-layer film production has become more competitive. The ABA machines are already prevalent in the Turkish market.

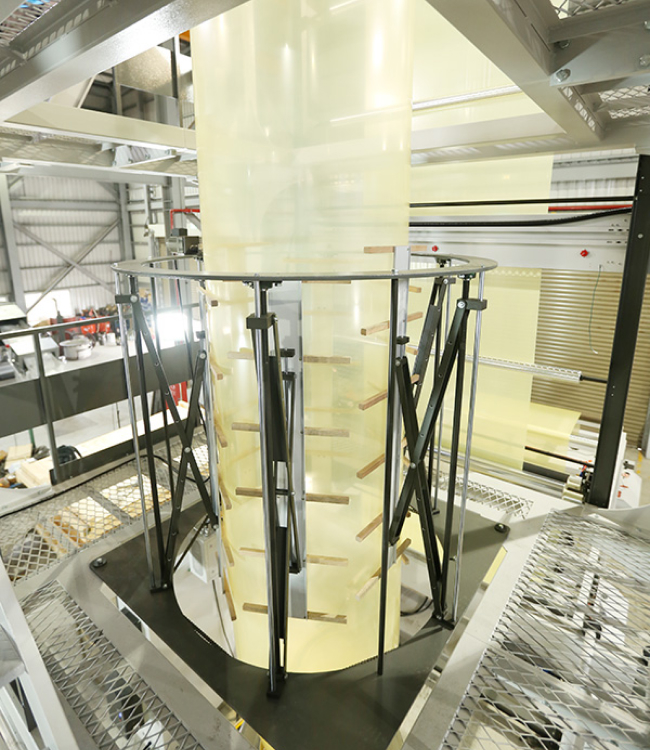

The A-B-A blown film machine consists of two extruders, normally of two different sizes. The most common ones today are the combination of a 45mm extruder with a 55mm or 55/65mm for T-shirt bag and garbage bag production. The B layer generally consists of 60~70% CaCO3. Recycled pellets (from in-house waste) can also be added to the mixture.

Excellent Material Mixing for Multi-layer Co-Extrusion Blown Film Line

The re-designed screw helps to achieve maximum efficiency during the film production process. A superior extrusion mixing can produce superb film quality, even when working with 70% CaCO3 and recycled material in the receipt.