We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

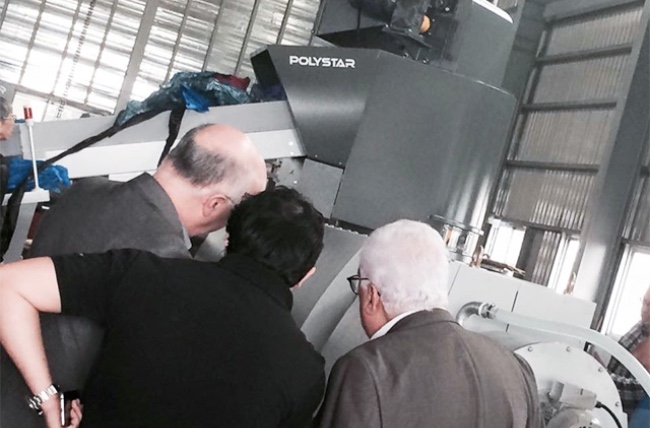

Recycling Machine Set Up in Morocco's Leading Film Producer

In January 2015, POLYSTAR successfully mounted another 500kg per hour film recycling machine in Morocco, currently reprocessing HDPE, LDPE and PP film waste from in-house. This is the third recycling line that the filmmaker has purchased since 2007.

The cutter-compactor integrated plastic recycling system is ideal for in-house recycling, particularly for film producers. It can reprocess complete film-on-roll as small as 300mm up to 2 meters in width without pre-cutting. Film scraps from blown film or printing start-ups as well as T-shirt bag cut-offs from bag making process are fed from the conveying belt. The plastic recycling system pre-conditions the material into a semi-molten state for the following extrusion process. The material is cut, homogenized, heated, dried, and compacted to ensure stable feeding and an end product of consistently high quality.

Plastic production waste is becoming more and more significant as a valuable secondary raw material. Escalating prices of primary resources forces the producers to minimize the use of raw materials to save costs. As a result, the plastic recycling system is a crucial line in film production today. On average, factories with more than 5 blown film machines need to acquire a plastic recycling machine to recover the waste that it produces, normally from defective film products, edge trim, or cut-offs. When the waste is recycled and kept in-house the quality of the recycled pellets can be better controlled.

The Repro-Flex Plastic recycling system is able to recycle HDPE as well as LD/LLDPE and PP. Shrink film, stretch film, and EVA film are also applicable to the plastic recycling system.