We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

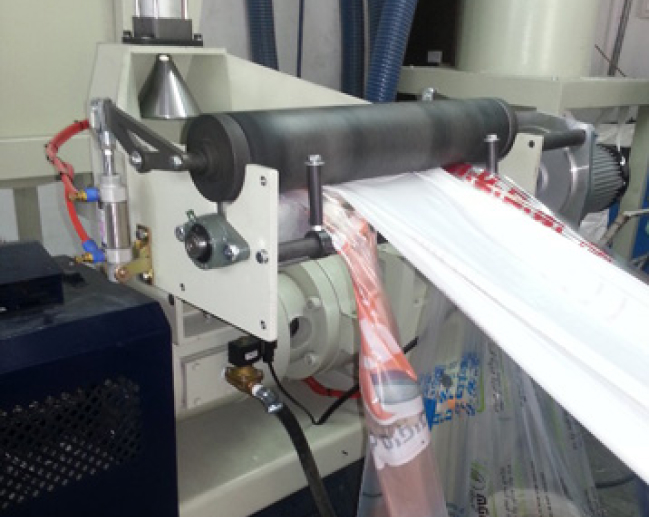

Recycling Machine for Blown Film Waste Operating in Israel

This recycling machine for blown film waste produces about 40~50kg per hour. Designed for in-house recycling, for the most part for film producers. It can recycle complete film rolls without having to pre-crush or pre-cut the waste. T-shirt bag bundles and cut-offs from the bag-making process can also be fed directly into this recycling machine for blown film waste. Recycling machine for blown film waste is an essential line in film production today, as in-house recycling considerably reduces the cost of virgin raw material.

On average, factories with roughly 8 blown film machines need to acquire a recycling machine for blown film waste to recover the waste that it produces, normally from edge trim or cut-offs.

The RP recycling machine for blown film waste can recycle HDPE, LDPE, and LLDPE film scraps, film roll, cut-offs, defective films from production, T-shirt bag bundles, and rejected film from in-house production. The advantage of this recycling machine for blown film waste is that it does not require any water.

A special cooling device -- The vortex system of this recycling machine for blown film waste, greatly enhances the cooling and separation of plastic pellets, enabling the air-cooled recycling machine to process HDPE, LDPE and LLDPE.

This recycling machine for blown film waste is extremely compact, space-saving, user-friendly and does not require any installation upon machine arrival.