We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Plastic recycling system in Azerbaijan

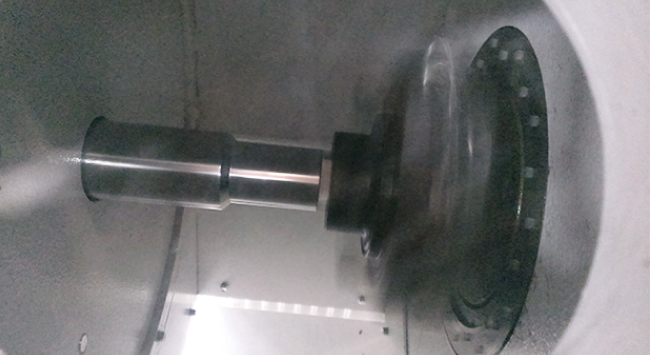

POLYSTAR has sold the 100th air pelletizing plastic recycling system RP-120 to the film manufacturer in Azerbaijan. The mini plastic recycling system was launched in 2008 as an affordable, compact machine to complement the established, high-output model HNT-V at Polystar. Since its launch, the air pelletizing line has been sold to film manufacturers worldwide.Established in 1995, the Sumgait-based company has focused on the manufacturing of various types of polyethylene film products, including handle bags, striped bags, carrier bags, and many other different types of packaging products. It supplies to well-known international companies such as Pepsi, Coca-Cola, Puma, and Adidas. Another production line was added in 2001 to produce greenhouse film and shrink film for a different sector. Besides supplying to the domestic market, it also exports to Germany, Turkey, and Russia.

Effectively Machine Recycle HDPE, LDPE, LLDPE Film Scraps

This compact, air-cooling plastic recycling system is specially designed for blown film and cast film producers. The model can effectively recycle HDPE, LDPE, LLDPE film scraps (mono and multi-layer), start-up or changeover film rolls (film-on-roll), edge-trim waste, T-shirt bag bundles (cut-offs) from in-house production. lightly-printed film can also be recycled into high-quality, uniform pellets.

Higher Output Capacity

The space-saving plastic recycling system RP-120 has an average output of 40~50kg per hour, 800~1,000kg per day. Through the nip roll feeder, the plastic recycling system can process multiple film rolls at the same time. T-shirt bag bundles (cut-offs) from the making process can also be put directly into the plastic recycling system without the need for pre-crushing.

Pellets Put Back into Production Line