We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

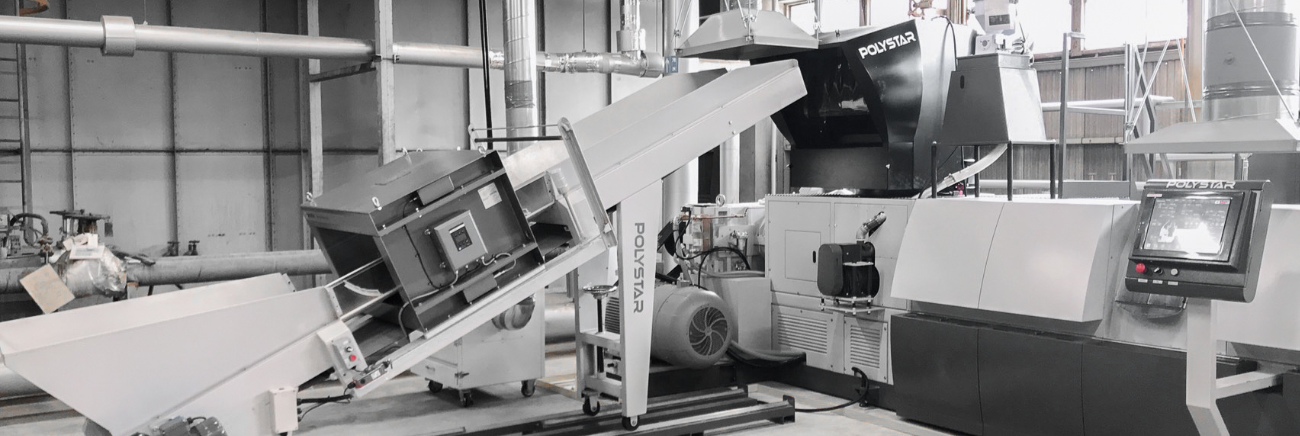

Japanese PP Fiber Producer Goes with POLYSTAR Recycling Machine

Precise PP Recycling for Enhanced Product Quality

Latest Technology Developments and Costumers' Core Benefits

- Integrated with smart driving module, enable to control the cutting speed via the die head pressure variation.To produce the uniformed size quality of recycled pellets.

- Customization of the pelletizing die head design according to different properties of the material. To come out with the best quality of recycled plastic pellets.

- Embedded with the patented air cylinder piston system to ensure the pressure of pelletizing blade constantly. To make the stable quality of recycled plastic pellets with long terms operation.

In accordance with the development of “ Industry 4.0”. This customer adopted with the advanced PLC + HMI control system to optimize their routine production management. Through “ Big Data Storage and Analysis” process, the customer can track back the historical production record via the iCloud data storage zone and find out the real roots cause if any trouble happening. Furthermore, the PLC control system is embedded with the remote control module, it allows the administrator to monitor even control the operation parameter from remote end. It also enhances the automation degree of the operation and shorten the timing of machinery repair and maintenance.

So far, the Japanese customer is running with POLYSTAR’s plastic pelletizer properly and keep increasing their production capability gradually. Averagely 0.30~0.35 kw/kg power consumption performance make the customer saving the energy efficiently; The customer estimated the ROI (Return of Investment) of POLYSTAR’s plastic pelletizer should be less than 1.5 years and will go with the second machine soon. With POLYSTAR’s professional after sales service support toward mechanical and electrical operation system, the mechanical and electrical manager of the customer mentioned that they are relived about the brand of POLYSTAR and will keep going with POLYSTAR for sustainable cooperation.