We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Plastic Recycling Machine Installation in Germany

Milestone Reached: 160th Re-engineered HNT-V Sold

After the installation of a 450kg/hr cutter-compactor plastic recycling system in Dortmund Germany in April, POLYSTAR, the Taiwanese plastic recycling system manufacturer, celebrates another milestone. This was the 100th re-engineered cutter compactor film recycling system that POLYSTAR has installed in a customer's factory since 2012. More than 160 units of the same model have been sold to 85 countries worldwide in less than 3 years. The plastic recycling system manufacturer's experience in producing this type of system gives customers much added value and reliability.

With more than 40% revenue growth every year since 2011, POLYSTAR is currently the largest manufacturer of plastic recycling systems in Taiwan. The biggest advantage of the company is its ability to supply customers with high-quality plastic recycling systems at a very affordable cost.

High-efficiency Plastic Recycling Systems with Fewer Processes and Higher Output

POLYSTAR, the plastic recycling system manufacturer, has been focusing on the re-engineering of its best-selling model, the HNT-V, which is designed specifically for post-industrial film recycling and reprocessing.

POLYSTAR, the Taiwanese plastic recycling system manufacturer, not only works with some of the biggest film producers around the world but also cooperates closely with many medium and smaller producers. As the plastic recycling system manufacturer provides customers with a wide range of capacities to choose from (50kg per hour up to 1,000kg per hour), most factories can easily find a plastic recycling system that is suitable both economically and productivity-wise.

Turn your Ex-factory Waste Back into the Production Line!

In general, plastic film waste and scrap recycling can be a problematic operation, since the low bulk density of the material can make high output difficult to achieve. POLYSTAR's plastic recycling system with an integration of a cutter compactor helps to solve this problem by giving the material a quick densification, before feeding it directly into the tangentially connected extruder. This process helps to achieve very stable and fast output compared to other methods in the market today. The plastic recycling system can process scrap material on a conveyor and film-on-roll on a nip-roll film feeder simultaneously.

__23K019psOY.jpg)

The plastic recycling system manufacturer's recycling machines, built for 24/7 reliable and easy operation, provide customers with a cost-effective way to reuse plastic, putting the waste and scrap back into the manufacturing process to increase profit margin. The like-new, high-quality recycled pellets give great value back to the film producers as they can be put directly back into the production line.

The plastic recycling system manufacturer's recycling machines are equipped with Siemens energy-saving motors and electrical components from Schneider. Compared to European machinery suppliers, POLYSTAR's machines have a much faster return on investment, providing high-quality recycling machines at a very affordable cost.

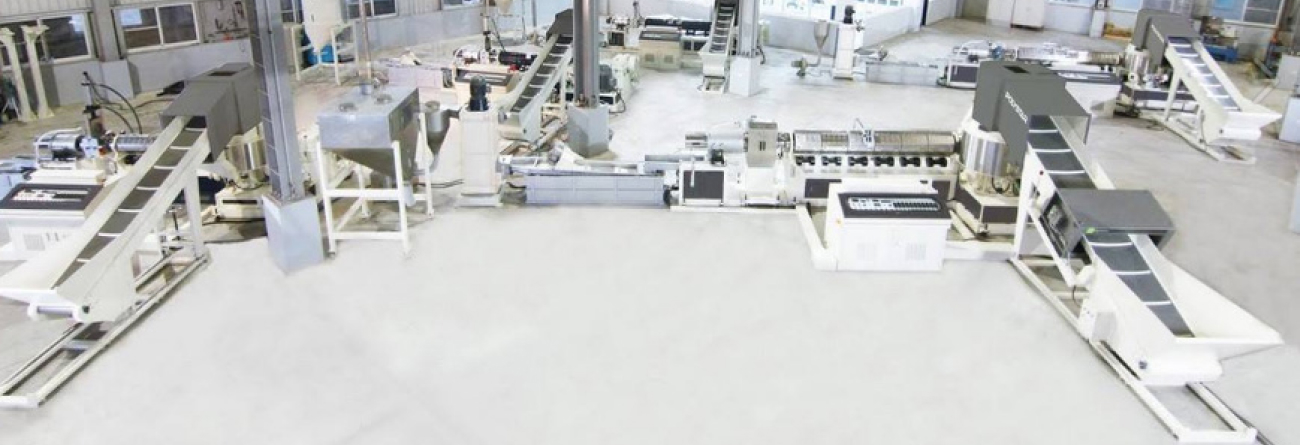

Exhibitions and Show Rooms

The plastic recycling system manufacturer will be presenting recycling lines in Plastimagen (Mexico) in November, TaipeiPlas 2014, and NPE (Orlando) in 2015.

The plastic recycling system manufacturer machine showrooms in the United Kingdom, Dubai, Russia, and India with live demonstrations have been receiving customers every week. The next step for the plastic recycling system manufacturer will be to open a showroom in Mexico and another one in South America, as the demand in the region continues to increase.

Click here to check: