We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

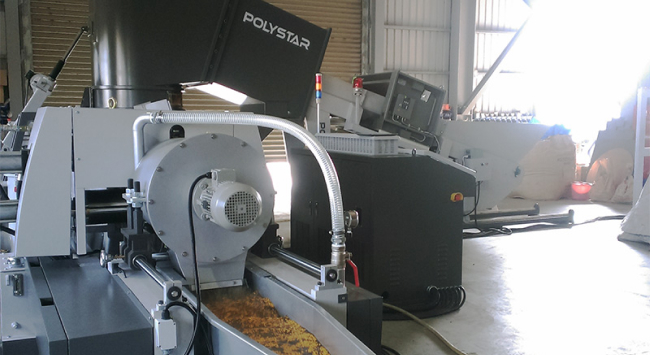

Bolivia takes two POLYSTAR Film Recycling Machines

Plastic Film Recycling Machines Installed in Bolivia

One of the leading plastic producers in Bolivia has decided to purchase two 500kg/hr POLYSTAR cutter integrated film reprocessing machines.

The Bolivia-based film producer made a fast decision immediately after seeing the lines operating in Chile which already has two POLYSTAR lines.

One of the plastic recycling machines will be used mainly for processing HDPE, LDPE/LLDPE, and PP-rejected film scrap, film rolls, and edge trim waste generated from in-house production. The other plastic recycling machine will be converting cut-offs and punches from thermoformed cups and trays of PP and PS.

Plastic Recycling Machine with Integrated Cut/Compact Technology

In general, plastic film waste and scrap recycling can be a problematic operation, since the low bulk density of the material can make high output difficult to achieve. It is hard to achieve high throughput with lightweight film flakes without going through the densification and compacting process first.

POLYSTAR's plastic film recycling machine with an integration of a cutter compactor helps to solve this problem by giving the material a quick agglomeration process before feeding it directly into the tangentially connected extruder. This process helps to achieve very stable and fast output compared to other methods in the market today. The plastic recycling machine can process scrap material on a conveyor and film-on-roll on a nip-roll film feeder simultaneously.

POLYSTAR's HNT-V plastic recycling machine is designed specifically for post-industrial film recycling and reprocessing. The one-step, high-efficiency recycling line with a cutter integration eliminates the need for pre-cutting and pre-conditioning of polyethylene and polypropylene film waste.

Ideal Solution for Blown Film and Cast Film Production Waste

The most commonly processed industrial waste from blown film and cast film productions are Printed and unprinted PE (HDPE/LDPE), PP, heavily printed films, edge trims, defective film roll scrap, multi-layer films (PE/PA), stretch and shrink films are ideal for this plastic recycling machine. In Latin America, POLYSTA not only works with some of the biggest film producers but also cooperates closely with many medium and smaller producers. As POLYSTAR provides customers with a wide range of machine capacities to choose from (50kg per hour up to 1,000kg per hour), most factories can easily find a plastic recycling machine that is suitable both economically and productivity-wise. In 2014, POLYSTAR has already commissioned multiple lines in Argentina, Bolivia, Colombia, Chile, Ecuador, Guatemala, Mexico, and Venezuela.