We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

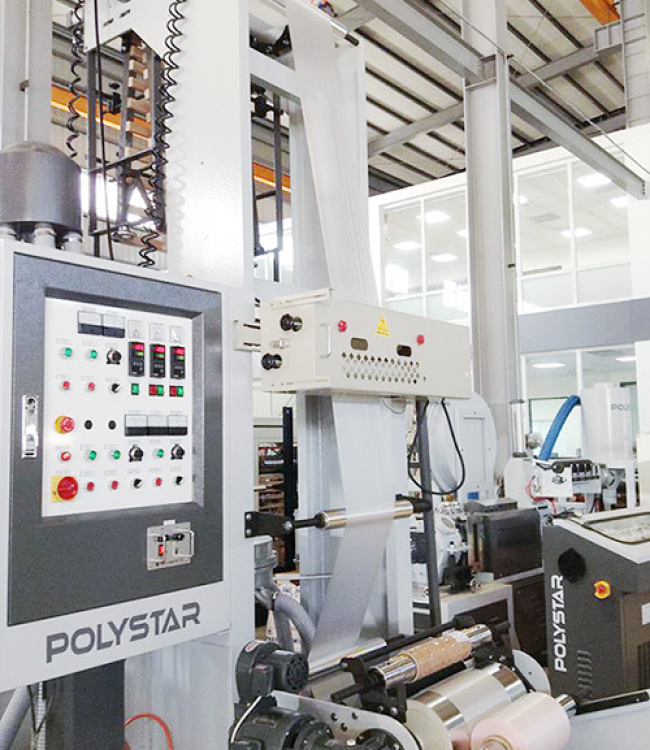

Blown Film Factory in Saudi Arabia

12 sets of the blown film made by POLYSTAR were mounted in Jeddah, Saudi Arabia in January 2014. Since the plastic production business is popular in Saudi Arabia, the demand for the product is also getting higher and higher, this customer had a plan to enter a new business at the end of 2012.

PE Film Factory in Saudi Arabia

Customers started to make business plans at the end of 2012. They collected some product sample which is popular in Saudi Arabia and sent them to POLYSTAR. After examining the sample, POLYSTAR recommended customer some machines which is suitable for producing the films for making the product.

This Customer Planned to Produce:

- T-shirt bag with a width from 10cm to 50cm. With and without gusseting

- Bottom-sealed flat bag with a width from 10cm to 35cm

- Garment bags with widths 30cm to 50cm

- Garbage bags with widths of 50cm to 100cm

POLYSTAR suggested the customer have the mini-type of blown film machine for making small-sized T-shirt bags and bottom-sealed flat bags (width 10cm to 50cm), HDPE films are suitable to be produced by this mini-type of blown film machine. The output of this mini-type blown film machine is on average 40kg/hr. POLYSTAR recommended the customer get 8 sets of this machine to the production line.

Tips and Recommendations for Small Bag Production

For producing films with a width of 50cm to 100cm, POLYSTAR recommended the customer have a 55mm extruder blown film machine. Two sets of this machine will be able to produce 50 cm to 100cm films for making garbage bags. The material will be HDPE blended with LDPE to make a tougher film.

To make a garment bag with a width of 30 to 50cm, POLYSTAR recommends customers use a blown film machine with a 45mm extruder for producing LDPE garment bags. POLYSTAR also suggested customers add some LLDPE material into LDPE material to make the film look brighter and will be tougher than films made from 100% LDPE.

After discussion, a customer visited POLYSTAR factory to see the machines. At the end of August 2013, the customer ordered 12 sets of blown film machines from POLYSTAR, including 8 sets of HDPE mini-blown film machines, 2 sets of 55mm extruder blown film machines, and 2 sets of 45mm extruder blown film machines. The machines were installed in Jeddah, Saudi Arabia in January 2014. After 6 months of working, the customer is very satisfied with POLYSTAR machines' performance and the service that we offer. They are planning to expand the production line in the 4th season of 2014.

Successful Cases of Blown Film/Bag-making Machine Combination

POLYSTAR offers customers detailed suggestions on the production line. For the past 3 years, POLYSTAR already successfully organized more than 20 projects for plastic bag production starters. The projects included a blown film machine, bag-making machine, printing machine, and recycling machine.