We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

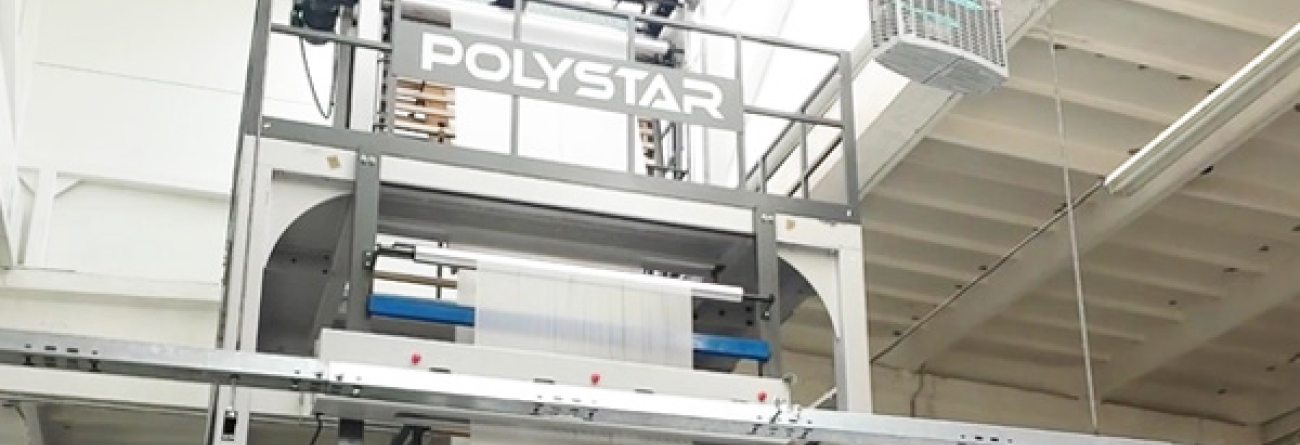

ABA Multilayer Blown Film Machine in Czech Republic

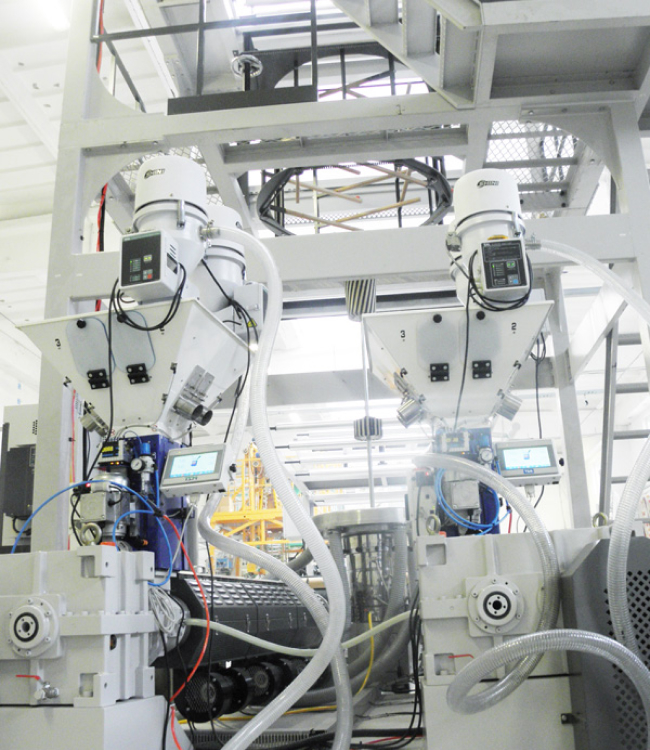

Another set of ABA Multilayer blown film machine is installed in Europe. Located in Czech Republic, customer installed 1 set of ABA blown film machine that is equipped with one 55mm extruder and one 65mm extruder. The multilayer blown film machine is capable to produce max. 1350mm HDPE film, and has average output 110~140 Kg/Hr.

The commissioned machine is mainly for producing the HDPE film with large quantity of CaCo3 filler. Films will be fed to converting lines to make commercial bags. By using the gravimetric 4 components dosing unit, the client is capable to control the accuracy of formula when mixing main material resins(either virgin or recycled) together with additives, fillers, and masterbatches.

The ABA Multilayer blown film machine offers more flexibility on film formula comparing to regular monolayer machines. Moreover, the three layer film is 30% stronger than regular monolayer film, and production cost can be saved upto to 50%. Based on the unique screw design, upto to 60% CaCo3 can be added to machine with excellent mixing effect.

ABA Multilayer blown film machine is already well known in Turkish market, and it has become very popular in worldwide markets nowadays. More and more film producers start to replace existing monolayer machines with ABA Multilayer blown film machine in order to stay competitive in the film industry.