We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

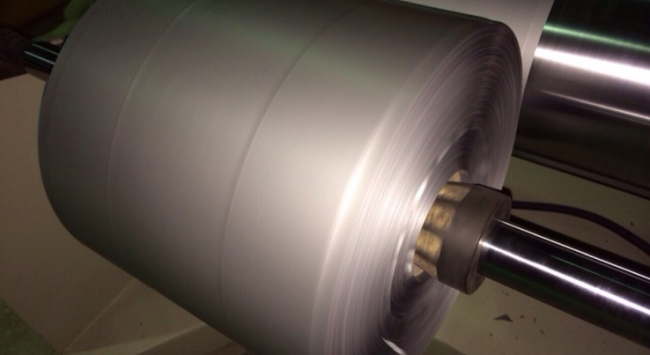

Co-Extruder Blown Film Line Mounted in Russia

In December 2012, POLYSTAR mounted a co-extruder blown film machine in Russia. The co-extruder blown film line is a three-layer ABA type, which is used for producing HDPE films blended with CaCO3. The film produced by the co-extruder blown film line is mainly used for making T-shirt bags and small-sized garbage bags.

Producing High-Quality 3-layer Plastic Film with Recycled Materials

The co-extruder blown film machine has two extruders for producing ABA-type, three-layer plastic film. In the middle layer, the film producers are using HDPE recycled pellets mixed with CaCO3. The CaCO3 can be used up to 70% in the middle layer. For the outer layer, a producer is using HDPE recycled material blended with 20% CaCO3 and silver color masterbatch, which is not easy to mix with other materials. The user is very satisfied with the material mixing ability of this co-extruder blown film line.

ABA Co-extrusion for T-shirt/Garbage Bags Production

Since the cost of virgin raw material keeps increasing, the ABA-type co-extruder blown film line is getting more and more popular with the T-shirt bag and garbage bag producers. Using recycled material and CaCO3 in the middle layer helps to reduce the cost of producing films. The final product will become more competitive in the market.