We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Successful Stories

A Japanese Producer Customized POLYSTAR's Plastic Recycling Machine for Its Fishnet Recycling Project

Takemura Co., Ltd., located in Mieken, Japan, is a renowned fishnet manufacturer in the local market. Their diverse products range from fishnets, bird nets, and light shielding sheets, to canvas products. With extensive knowledge and experience, they stand as a leading fishnet manufacturer in Japan. They are satisfied with the flexibility of our plastic recycling machine, which meets their specific needs, and the space in their factory, also impressed by the high output quality with the simple designs.

Daisaku Co., Ltd. and POLYSTAR Collaborate to Lead Japan's Plastic Waste Recycling Industry

DAISAKU CO., LTD, located in Ibaraki Prefecture, Japan, is a leading enterprise in the plastic waste recycling industry. We have been collaborating with POLYSTAR since 2019 to enhance our plastic recycling business. Our partnership with POLYSTAR includes the purchase of their Repro-Flex 150 recycling machine to process various HDPE/LDPE/LLDPE packaging film/bale film/shrink film waste. The machine is highly efficient and can convert plastic waste into uniform-sized and high-quality recycled pellets. With a production capacity of up to 700 kg/hr, we have successfully sold these recycled pellets with excellent quality to both domestic and overseas markets. Our company's reputation and supply quality have enabled us to sell our products in more than 20 overseas markets.

Turkish CPP Cast Film Producer Recycles Factory Production Waste with POLYSTAR

A well-known Turkish CPP cast film producer Kamel Cast Film recycles its edge trim wastes with POLYSTAR’s Repro-Flex plastic recycling machine. Instead of throwing away these edge trim wastes, the company sells them as high-quality, virgin materials like recycled CPP pellets in the local market and Europe region. The buyers of recycled CPP pellets use them in the production of several different plastic packaging products.

Turkish Plastic Recycler Grows with POLYSTAR

At the end of 2022, POLYSTAR attended Plast Eurasia and cherished once again meeting many of its customers and visitors from Türkiye and neighboring markets. The showcased Repro-Flex plastic recycling machine took a huge interest of local and international visitors with its compactness and flexibility. Moreover, Repro-Flex was installed at Sembol Geri Dönüşüm, Istanbul based leading plastic recycling center, just after the exhibition.

BOPP Food Packaging Producer in Argentina Recycles His Industrial Waste Using POLYSTAR

With sustainability goals and ESG regulations being implemented more widely, plastic producers are looking for ways to reduce their waste and become more eco-friendly, such as implementing an industrial recycling program. The BOPP food packaging exporter, Vitopel Argentina, is no exception. The company has recently expanded its recycling line by adding a cutter compactor integrated recycling machine (Repro-Flex) to its factory.

Turkish Flexible Package and Courier Bag Producer Now Recycles Production Wastes In-house

Global polymer price increase and the obstacles to reach out the resources, push many manufacturers to find alternative solutions. One of the most effective methods is in-house recycling of factory production wastes. Istanbul, Esenyurt based flexible package and courier bag producer Sürmeli Plastik has also started to recycle its own production wastes within the factory by Repro-Flex 100.

Bag Producer in Ecuador Uses Up to 100% Recycled Material to Reduce Cost

Plastic packaging production and demand, as well as recycling, have increased in Latin America. As a result, having machinery that produces high-quality and long-lasting finished goods is critical. You'll see how Plasticonsumo has found the ideal supplier to meet the needs of a plastic producer.

Stretch Film Plastic Recycling Machine - How In-house Recycling Improves Pellets Reusability?

In-house recycling of stretch wrap, pallet wrap and shrink wrap waste significantly reduces the cost. Therefore, Taiwan’s leading stretch film producer invests in POLYSTAR’s stretch film recycling machine.

PP Woven Sack Recycling Machine Commissioned in Nigeria

One of the leading PP (polypropylene) woven packaging manufacturers in Nigeria has recently acquired the Repro-One PP sack recycling machine to process its post-industrial waste. The company has focused on the production of PP woven bags and PP jumbo bags for over 20 years. On average, the production lines generate 2 ~ 5% waste from tape extrusion lines, printing lines, and start-up lumps.

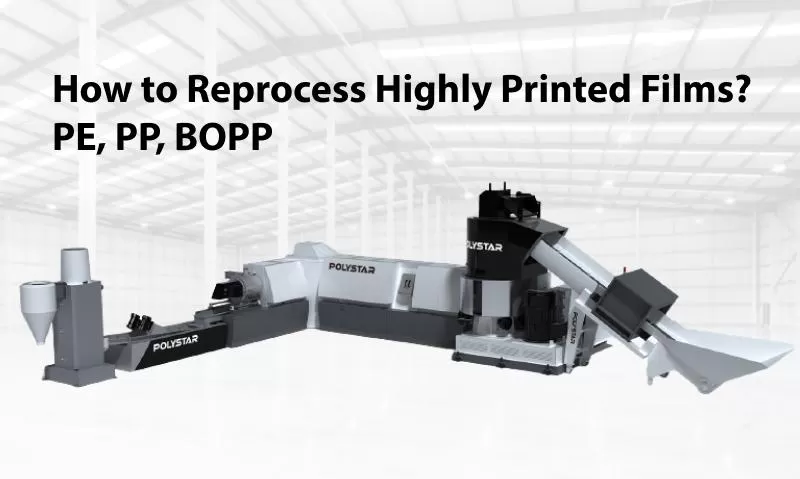

How to Reprocess Highly Printed Films? PE, PP, BOPP

The industry of plastic has been changing and evolving over the years that’s why plastic recycling has become a necessity among plastic producers. The laws toward plastic have become stricter, which require the producers to use a higher percentage of recycled material in their final products. The benefits of these laws are for lowering the production cost of the producers and reducing the plastic waste in our environment. POLYSTAR, through reengineering, designed the perfect solution: Repro-Flex Plus.

US Recycler Shares His Experience Using POLYSTAR

Managing director of the Tennessee-based recycler, Mr. Irvin Payne, shares his own experience with Polystar recycling extruder. My experience includes installing and operating American extruders and German extruders for over 30 years. My opinion of Polystar is they do a very good job of designing and building extruders and for the price, cannot be matched. I looked at buying a German machine at three times the cost before I decided on the Polystar.

ABA Blown Film Machine – What’s the advantage?

For PE bag production, single layer blown film machine has been the most common type of extruder to use. It is probably still the best machine for products such as fruit and vegetable bags (perforated bag-on-roll) that use mainly virgin materials with low film thickness ranging from 6 to 18 microns. Single layer machine is also the favorable choice for biodegradable bag production.

Raffia Producer Now Recycles in One Step

POLYSTAR’s Repro-One recycling machine provides solutions to the problems of post-industrial recycling of PP raffia, woven sacks, tapes, non-woven/woven, FIBC and jumbo bags . These materials would be challenging to recycle at some points. But not anymore with POLYSTAR.

Air-Cooled Pelletizer Increases Reusability Percentage of Pellets Back to Bag Production

The air-cooled pelletizing recycling machine Repro-Air has proven to be a big cost-saver for two of the largest PE bag producers located in Solo, Indonesia – Cahaya Kharisma and Djerapah Plastindo. According to the well-known HDPE and LDPE bag producers, the air-cooled pelletizing technology is even better than water-cooled recycling machines for some applications, especially for the recycling of HDPE and LDPE non-printed film.

PE Bag Producers Step Up in Quality and Efficiency in Vietnam

The Vietnamese plastic sector has grown significantly in the past 5 years thanks to many unique advantages that the country has. The ability to produce lower cost yet good quality plastic products is ideal for export markets such as the US, Japan, Europe, Australia and Cambodia. The local market demand is also increasing in sectors such as live seafood packaging, industrial and agricultural film, in a country of large population of nearly 100 million. Since 2016, Polystar has already been working with 42 producers in Vietnam and has installed 187 sets of blown film extruders for various applications such as general packaging (garbage bags, vegetable and fruit bags, shopping bags), seafood packaging and industrial packaging.