We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Post-consumer and Post-industrial Plastic Recycling Demand is Growing

Source: Plastech

Date: 18/11/2022

It may be good for everyone to be in the plastic recycling business whether you are a recycler or a producer.

New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. The instability of raw material prices and supplies also forces plastic producers to better recycle their production waste.

With the great importance of recycled-based plastic products, the global demand for plastic recycling is expanding. Recyclers are now purchasing more advanced technologies and much plastic equipment at once, as well as bigger pelletizing extruders.

Cutter-compactors Increase the Output of Large Plastic Recycling Lines.

A cutter compactor has a clear advantage, especially for larger-sized recycling extruders. Through natural heat and friction generated from the rotation, it can quickly compact and densify the lightweight material into a more solid form to be fed into the extruder at a constant rate.

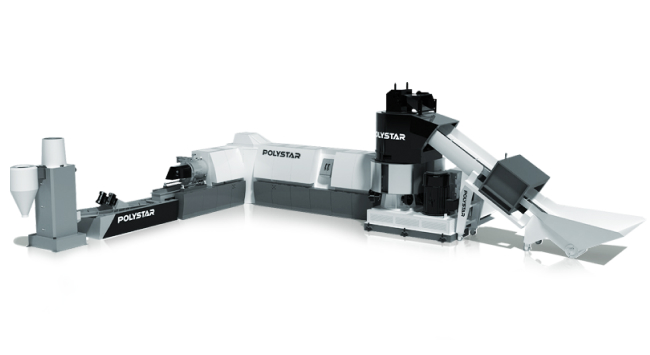

That’s why the Repro-Flex model from a Taiwan-based recycling machine manufacturer POLYSTAR has become one of the most popular models among recyclers due to its high level of efficiency and stability in recycling both soft and hard plastic scraps in a variety of forms. As of today, 1,200 Repro-Flex recycling machines are in operation worldwide.

Two-stage Plastic Recycling Machine Adds Flexibility for Recyclers

For recyclers who process washed and fully printed post-consumer waste, POLYSTAR offers an option of adding a second extruder to the Repro-Flex model. Also having a cutter compactor built in and operating with the same working principles, the two-stage model Repro-Flex Plus has a total of three degassing zones and two filtration steps throughout the entire recycling process. This model is also ideal for processing post-industrial laminated/multi-layered waste.

When processing post-consumer materials, the cutter-compactor reduces the ink and moisture level of the material coming from the washing lines, such as washed flakes (from film and woven bags) as well as regrind waste from milk and shampoo bottles. At the same time, it stabilizes the material being fed into the extrusion pelletizing line to ensure consistent production output and better pellet quality.

Shredder Integrated Plastic Recycling Machine Extruder can Process Raffia In-house Waste in One Step.

The reusability of recycled pellets has become more important than ever for plastic producers who recycle and reprocess their in-house waste. Besides packaging film producers, woven bag producers now also require higher quality recycling (minimal material degradation) to reduce production costs as much as possible.

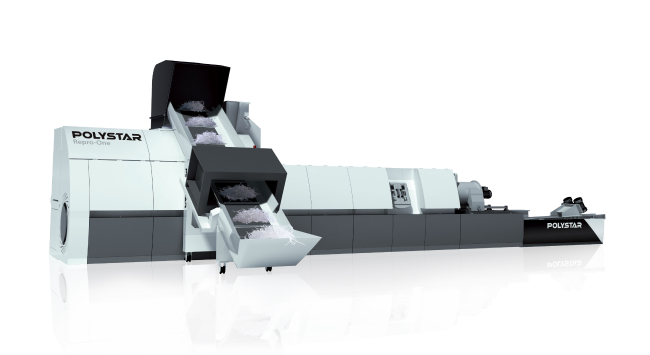

The Repro-One recycling technology from POLYSTAR is a combination of shredder, extruder, and pelletizer in one machine. This one-step, powerful (shredder) yet gentle (low processing temperature) process produces the best possible pellet quality at the lowest operation cost, enabling the producers to reuse all of the pellets back in PP tape extrusion lines.

In India, the requirement for more advanced recycling machines is rising, especially for PP raffia, woven bags, and FIBC producers who need to process their internal waste. More than 105 Repro-One recycling machines have been installed in the sector of India alone, and 350 more around the globe.

Less Expensive to Maintain. Faster Delivery.

Lower maintenance cost is a key advantage of using a POLYSTAR. The cost of consumable parts is 2.5~3 times lower compared to European machine suppliers of similar built quality.

With the new (third) facility in Taiwan, POLYSTAR has been able to better serve our customers with faster machine delivery time and in-time spare parts support; keeping a large number of critical machine components in stock. For standardized machine models from POLYSTAR, the lead time is only 4-6 months.

As the demand for recycling machines remains strong, POLYSTAR continues to prepare in-stock recycling machines and spare parts to avoid long delivery times, providing their worldwide customers with simple solutions.