We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

POLYSTAR-Recycling Made Simple for Circular Economy Value

Source: AdSale

Date: 14/07/2021

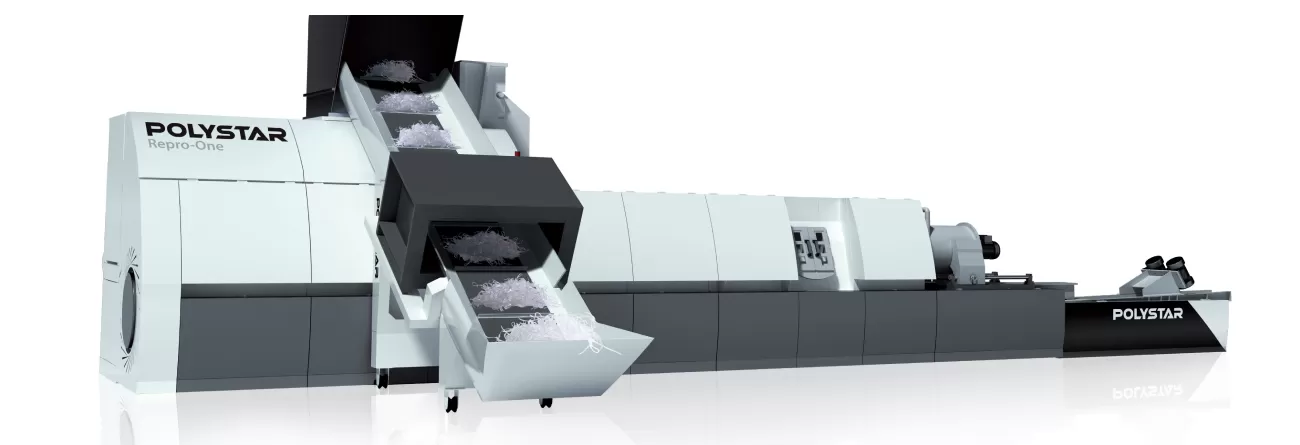

In response to the increasing demand for film bag scraps and solid structure material processing, POLYSTAR has developed a highly efficient shredding integrated recycling machine with innovative value and benefits. This recycling machine perfectly integrates the shredder all in one step and is equipped with advanced energy-saving feeding technology to ensure the optimization of the feeding. In terms of the filter system, an innovative back-flush filter system with a unique melt flow channel design and segmented clock control effectively enhances the automation of the slag discharge process and reduces the operation cost of screen replacement.

The Importance of Pelletizing

The pelletizing system is the core section of the recycling machine. POLYSTAR utilizes innovative digital programming technology with ECO energy-saving inverter modules to develop a fully automated pelletizing system. By automatically adjusting the speed of the pelletizer along with the die head pressure, a uniform size of recycled pellets can be produced.

In the aspect of Industry 4.0 intelligent manufacturing, POLYSTAR adopts a smart PLC control system and integrates a highly user-friendly HMI, which significantly shortens the learning curve for operators. The PLC control system is embedded with the remote-control module which can perform online troubleshooting, automatic preheating, big data collection and analysis, and parameter optimization through Cloud IP base control. The innovative technology of this machine has been applied to customers in Europe, Japan, the United States, India, and the Middle East …..and has been highly valued.

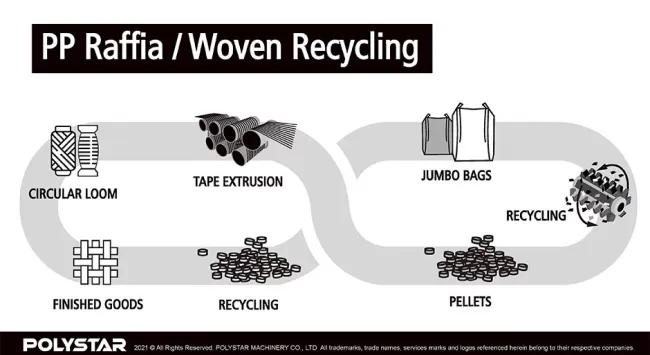

Circular Economy

As global environmental protection awareness keeps rising, the development of the circular economy has turned out to be a crucial tendency in the industry. POLYSTAR develops various turnkey recycling solutions to meet diversified requirements from global customers, such as Repro-Flex cutter compactor integrated recycling line, Repro-One shredder integrated solution, Repro-Flex Plus for PCR material processing, and so on…. The plastic waste can be directly fed into POLYSTAR’s highly efficient recycling machine and converted to superior quality recycled pellets, it can be 100% reused back to the production line to save the new material purchasing cost and reduce the waste effectively. We aim to contribute the new ECO-Green value for the industry and to be more friendly to the earth.

With customers’ valuable feedback and operation suggestions, POLYSTAR keeps innovative and steady improvements to strengthen our core values and competitiveness.

The product development appeal is based on " Exquisite Simplicity, Excellent Quality, and Steady Improvement" as its core value. We expect customer feedback to become the main driving force for our continuous growth and fulfill our social responsibilities to achieve the goal of sustainable operation