We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

POLYSTAR - Another Recycling Machine Running in Ibaraki Japan Successfully

Source: ADSales

Date: 18/05/2020

With the effect of POLYSTAR’s recycling machine running in the Japanese market successfully, the reputed recycler located at Ibaraki Japan decided to go with POLYSTAR. Established in 1963, the customer devote himself as a professional recycler. They purchased the post-industrial and post-consumer grade waste from all sectors of the economy, including the blown film extrusion industry, food packaging film industry, injection molding, and blown molding industry. That is made possible by consisting of five recycling lines in their facilities and should be able to expand their business scale in the near future.

“Expansion is necessary for the enterprise's long-term survival and make sure holding the sufficient market share in this fierce market competition", says CEO Mr. Kobayashi. Not only cultivating at the Japanese market, Mr. Kobayashi also extends the business scale to foreign countries, including the USA, UK, Korea, China, India, Thailand, Indonesia, Middle East, and Africa market. We deeply believe that simple & easy machinery operation and maintenance is the key to a successful recycling business, and the excellent quality of the recycled pellets produced by the “Simple” recycling machine is another contribution to the business management, it relatively saves the operation cost and enhances the production performance. POLYSTAR truly plays an important role and performs well in “Simple” machinery design and quality insurance, impressively mentioned by Mr. Kobayashi.

Overcoming Pandemic Challenges: POLYSTAR's Recycling Line Installation Enables Commercial Success

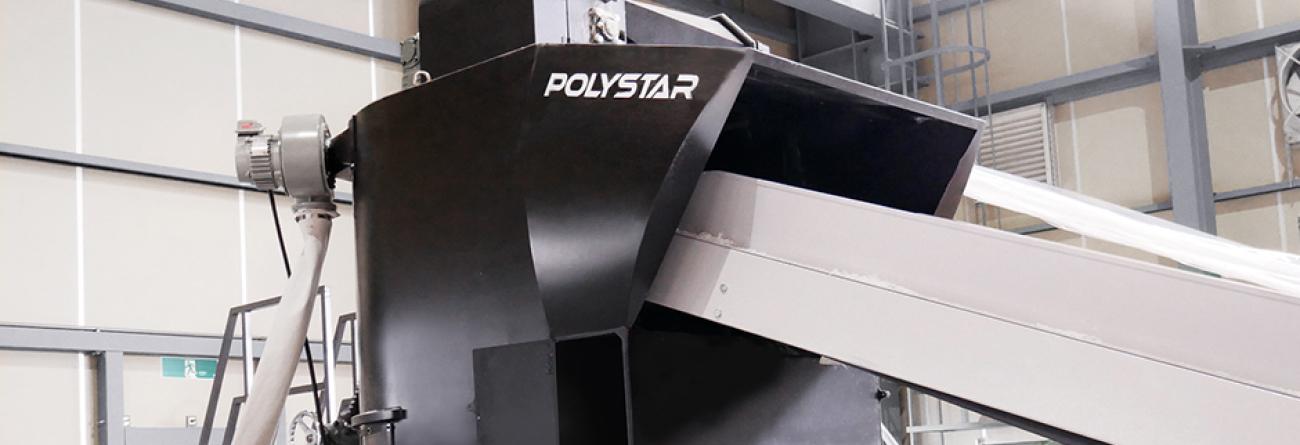

Owing to a new recycling hall being built and the filled order demand, the customer requested POLYSTAR’s recycling line installed on new land in time. However, due to the COVID-19 pandemic outbreak happening in Feb 2020 POLYSTAR’s technician is prohibited from installing the machine in the customer’s factory. Thanks to the simplest structure design, User-Friendly interface, and professional online remote installation guidance by POLYSTAR, it facilitates the successful installation of the machine and creates indispensable commercial value for both companies. Finally, a Repro Flex 150 with processing HDPE/LDPE/LLDPE film and bag scraps is stably reaching 600~650 kg/hr capacity at their new factory. These excellent quality recycled pellets are mainly sold to big film/bag producers and used in shrink and construction film production as well as for intermediate layers in laminated films.

The factory manager of the customer indicated that the size uniformity of recycled pellets is the critical point related to the homogeneous level and quality of their final product. Utilizing POLYSTAR’s intelligent pelletizing system and the patented air cylinder pressure control technology significantly stabilizes the quality of the recycled pellets and enhances the level of production automation. With POLYSTAR's latest intelligent pelletizing system and corresponding air cylinder pelletizing pressure control technology, it firmly ensures the reliability and uniformity of the recycled pellets and significantly increases our business profit.

Maximizing Recycled Pellets Reusability

Apart from the recycling business, the customer also utilizes the recycled pellets back to the production line for housewares products, such as the patented sonic driver for toothbrushes….etc. We aim to recycle every possible plastic waste and convert it into useful material for “ Green” environmental protection. POLYSATR’s simple but powerful machinery design concept has been affirmed by global customers and a professional in-time service attitude is the decisive criterion for our long-term cooperation, says Mr. Kobayashi in conclusion.