We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

One-Step Plastic Recycling Machine HNT-V: Combines Cutting, Extrusion and Pelletizing

Plastic Pelletizers are Being Equipped Widely in Different Industries

In addition to in-house (post-industrial) film waste, the system is also able to process washed flakes, scraps, and regrind (pre-crushed rigid plastic waste from injection and extrusion). This equipment is highly recommended for packaging film producers of commercial bags, garbage bags, agricultural films, food packaging, shrink and stretch films, as well as producers in the woven industry of PP woven bags, jumbo bags, tapes, and yarns. Other types of materials such as PS sheets, PE and PS foam, PE net, EVA, and PP mixed with PU are also applicable to this machine.

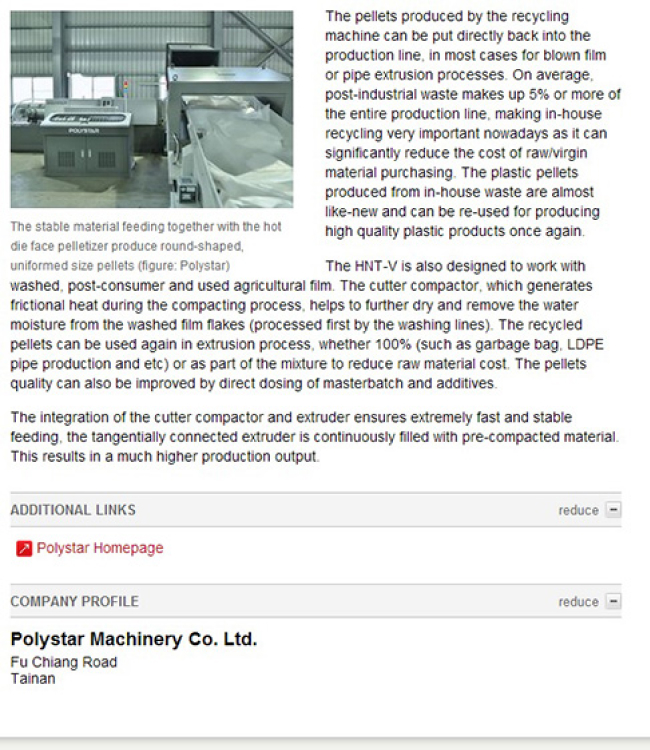

The pellets produced by the recycling machine can be put directly back into the production line, in most cases for blown film or pipe extrusion processes. On average, post-industrial waste makes up 5% or more of the entire production line, making in-house recycling very important nowadays as it can significantly reduce the cost of raw/virgin material purchasing. The plastic pellets produced from in-house waste are almost like new and can be reused for producing high-quality plastic products once again.

Plastic Pelletizing Machine with Integrating System

The HNT-V is also designed to work with washed, post-consumer, and used agricultural film. The cutter compactor, which generates frictional heat during the compacting process, helps to further dry and remove the water moisture from the washed film flakes (processed first by the washing lines). The recycled pellets can be used again in the extrusion process, whether 100% (such as garbage bag, LDPE pipe production and, etc.) or as part of the mixture to reduce raw material cost. The pellet’s quality can also be improved by direct dosing of masterbatch and additives.

The integration of the cutter compactor and extruder ensures extremely fast and stable feeding; the tangentially connected extruder is continuously filled with pre-compacted material. This results in much higher production output.