We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

For POLYSTAR, Quality’s the Core Value

Source: Sustainable Plastics

Date: 31/05/2024

POLYSTAR, which has grown into one of Asia’s most influential recycling equipment brands, said that demand from the first group is growing rapidly. “Their willingness to invest on the part of plastic processors stems from a desire to be able to control the quality of the material to be recycled,” explained Lo.

Collaboration

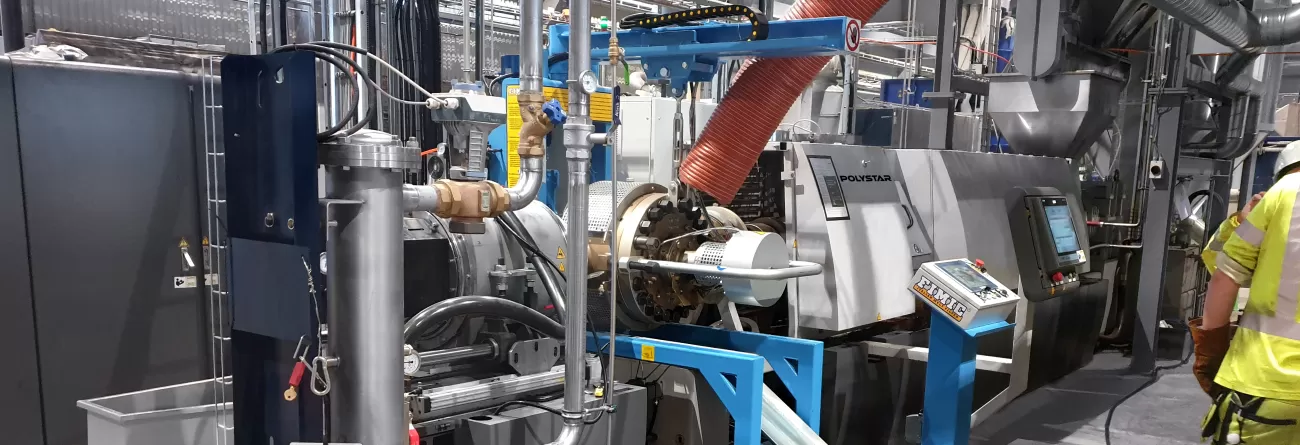

The machine on show at NPE 2024, the Repro-FlexPlus, is a two-stage cutter compactor integrated plastic recycling machine for heavily printed film, laminated film, and post-consumer waste. This plastic pelletising system includes two extruders, three degassing zones, and two filtration units to enhance filtration and degassing ability. It is ideal for processing post-industrial laminated and multi-layered waste.

“We have partners, whose products we integrate into our system because they provide the professional quality our customers’ demand. We cooperate, for example with FIMIC, using their self-cleaning melt filter as well as with a German company that has developed a very fine mesh filtration system. We are very focused on ensuring the recycled pellets are clean and have therefore included two filtration units in the system,” said Lo. “But we still need to really rely on some outsourcing to build the perfect solution for the customer.”

The Repro-Flex Plus system has an integrated cutter compactor that reduces the ink and moisture level of the material coming from the washing lines, such as washed flakes from film and woven bags as well as regrind waste from milk and shampoo bottles. At the same time, it stabilises the material being fed into the extrusion pelletising line to ensure consistent production output and better pellet quality.

The triple degassing unit features double degassing in the first extruder, with the venting area serving as a third degassing section to further remove the ink and extra moisture from the material, enabling the system to handle materials with up to a 95% printed surface.

Differentiation

In the almost four decades since its founding, the Taipei extruder producer has grown into an internationally recognised recycling machinery producer. According to David Lo, part of this success is attributable to the continuous R&D work the company carries out to maintain its program of continuous improvement and innovation. “We take the feedback we get from our customers very seriously,” said Lo. “They are asking for more energy efficiency, even better filtration, automatic backflushing – these are all features we are continuously working to improve. We are also working on the development of some of the components we currently buy to integrate in our systems, to produce these ourselves, as well as more advanced solutions. We want to be able to offer a full end-to-end POLYSTAR system. But that is still in the future.”

POLYSTAR annually invests around 3% of its budget in R&D. Asked about where its customers come from, it became clear that the company operated at a truly global level. “We deliver to customers in India, Japan, Mexico, Chile, Colombia, the EU to name but a few. The PRSE is an important show for us to expand our presence in Europe. Our main market is Southeast Asia, because it is close to home. In terms of service and maintenance, that’s convenient for our technicians.”

The company is now purposely eying the US market, which is why it attended the NPE. “The potential demand is there - the internal market is huge,” noted Lo.