We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

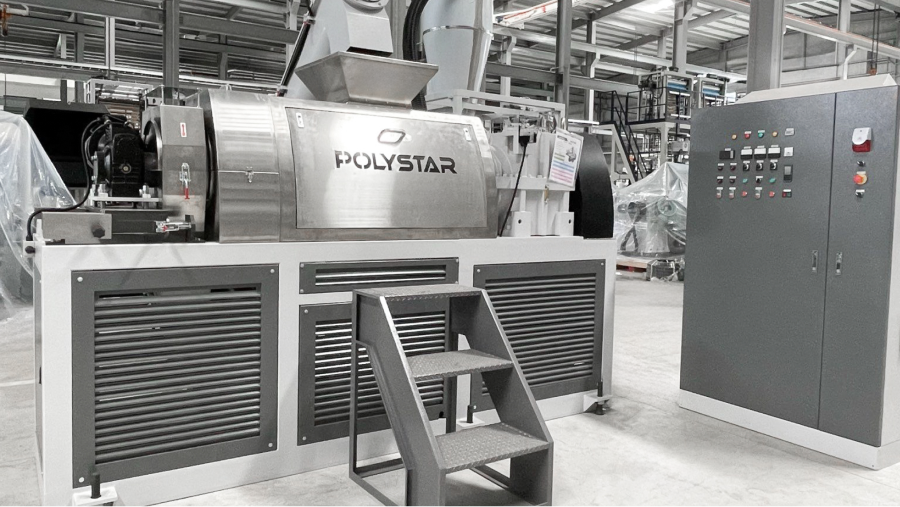

Squeezer Drying Machine (for washed film)

Squeezer Drying Machine (for the washed film)

Recycling Processes of Repro-Dry

-2__23L07mPrKX.png)

-

1. Feeding

Feeding the wet plastic scraps by belt/screw conveyor. -

2. Water Discharge (Squeeze)

The specially designed short screw “squeezes” and presses out the remaining moisture out of the washed materials. -

3. Final Product

The end product from the drying machines is in granule shape, which can be transported to the recycling pelletizing extruder easily.

Main Function

- For pre-washed material (coming directly from washing lines):

Post-consumer PE film, PP woven, PP jumbo bags, and agricultural film, in the form of flakes after washing. - Reduces water moisture level down to 1 ~5 % from 10~35%.

- Turn film flakes into solid lumps – higher density, and less volume result in faster, easier, and more stable feeding to the extruder.

- Faster drying of washed film and woven waste compared to conventional drying methods such as centrifugal drying or blow drying using hot air.

- The drying process generates less heat. This results in less material degradation, higher value, and higher reusability of recycled pellets.

- Prepares the material for the extrusion-pelletizing process that follows.

Benefits of Using the Squeezer Dryer

-

Increase Extruder Efficiency:

Increases output capacity and efficiency of the pelletizing extruder and the overall recycling process.

- Improve Pellets Quality:

After squeezing, the volume of the material goes down and the feeding to the pelletizing extruder becomes much easier and more consistent. As a result, the quality of the end product (recycled pellets) also improves.

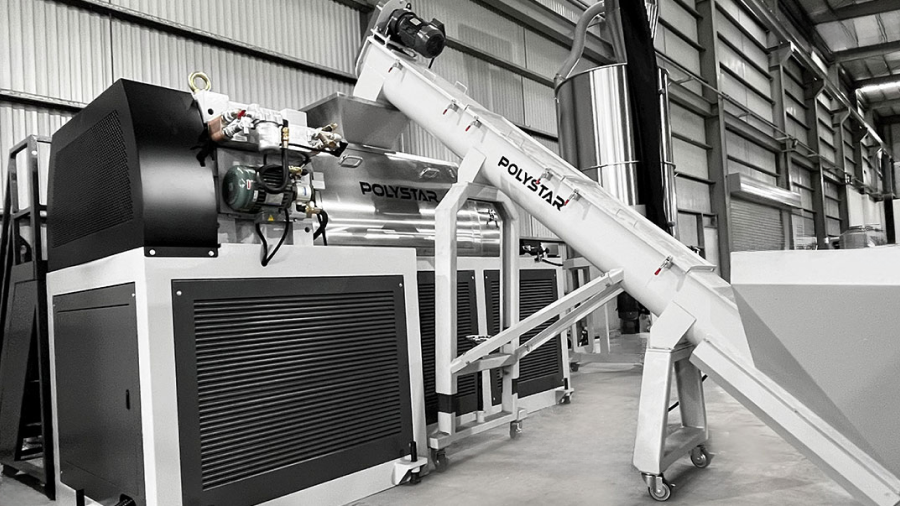

Integration with Recycling Extruder and Washing Line

-

Maximizes Output:

Maximizes output when working in line with the combination of the compactor-extruder-pelletizing type of recycling machine. -

Special Designed:

To fit between the washing line and plastic recycling extruder to increase output and efficiency. - Workflow:

Washing line → plastic squeezer dryer → plastic recycling extruder

-

Washed Film flakes

Washed Film flakes -

Washed Jumbo Bags

Washed Jumbo Bags -

Plastic Regrinds

Plastic Regrinds