We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Blog

Categories

Categories

Exploring the Blown Film Extrusion Process for Plastic Bags

Explore the Blown Film Extrusion Process for Plastic Bags! From polymer selection to the final touches in film extrusion, learn how plastic bags are crafted.

Maximize Plastic Film Sheet Production with One Machine

Choosing the right size of blown film machine is crucial when planning your production, and a key factor in doing so is the maximum width of the film you will produce. However, if your goal is to produce narrow plastic film sheets, we have a clever strategy to help you maximize your output.

Recycled Materials as a Key Element for Blown Film Extrusion in Latin America

The demand for recycling and plastic extrusion machinery in Latin America has seen a significant rise. With the increased adoption of sustainable processes and changing industry regulations, more producers are choosing POLYSTAR machines to align their products with market requirements. POLYSTAR has become a reliable partner for producers and recyclers of post-industrial and post-consumer waste in the region.

Advanced yet Easy-to-Use Blown Film Extrusion Technology – Key to Eco-friendly Packaging

Eco-friendly packaging is a necessity more than a trend, for both environmental and economic sustainability today.

Exploring Different Industries and Product Uses for Plastic Films

Let’s explore the widespread usage of PE film products across different industries. Furthermore, we will provide a machine guideline for your reference if you would like to produce these popular plastic film products.

Frequently Asked Questions About Blown Film Machines

In this blog, we will answer some of the most common questions we receive about our blown film machines.

How to Produce a 3-Color Plastic Film

Using tricolor striped film or 3-color film in plastic products is a popular method for producers. In this blog, we will explain how to produce this appealing tricolor striped plastic film.

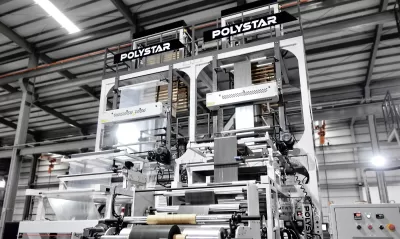

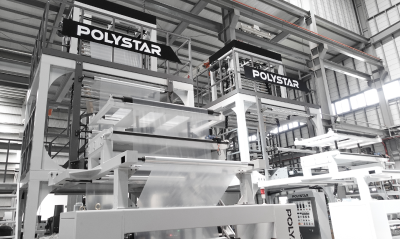

Advantages of Using Monolayer Blown Film Machines for Plastic Packaging

Star-X Mono Layer Blown Film Machine has become a popular choice of plastic packaging film and bag producers due to its versatility in producing different types of products, cost-effectiveness, and ease of use.

Common Uses for 3-Layer Blown Film Machines in the Plastic Industry

3-layer or multilayer plastic films are highly demanded in the packaging industry due to their superior tear and heat resistance, as well as excellent moisture and oxygen barrier properties.

Common Uses for 1-Layer Blown Film Machines in the Plastic Industry

Film produced with one-layer blown film machines is a versatile and cost-effective solution for applications from food packaging to bags of different types.