We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Why to Use Recycled Plastic Pellets for Injection Molding instead of Regrinds?

Using recycled plastic pellets for injection molding brings several benefits to businesses as well as to the environment. These can be listed as reducing waste, conserving resources, saving material costs, improving sustainability, and creating positive public relations. Recycling injection molding manufacturing wastes is one of the fastest ways of generating recycled plastic for injection molding. On the other hand, using recycled plastics in injection molding in pellet form is also found superior to regrind form by many injection molding manufacturers.

First of all, let’s understand the types of injection molding manufacturing wastes, then mention the benefits of recycling and reusing them in the manufacturing process as pellet forms instead of regrind forms.

What are the production wastes that can be re-used in injection molding?

During the plastic injection molding process, production wastes are generated because of various reasons. Recycling injection molded plastics and re-using them is a cost and time-savvy implementation. Furthermore, injection molding is one of the most welcoming plastic molding processes for recycled plastics.

Types of injection molding production wastes:

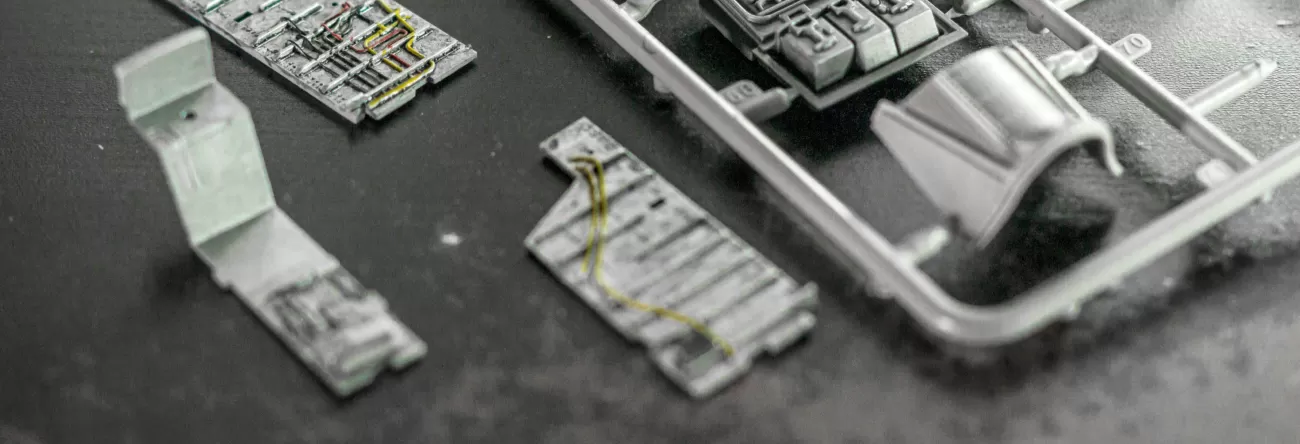

- Defective products that do not meet the standards

- Injection molding flash that overflowed the mold cavity

- Injection molding runner wastes

- Trimmings of the molded products

- Purging lumps that were used to clean the machine

Why should producers recycle injection molding production waste?

Recycling injection molding production wastes is beneficial for the environment as well as for businesses. While turning these wastes into valuable plastic materials, businesses can also help to achieve a more sustainable environment.

In terms of environmental benefits, recycling injection molding wastes and using them back in manufacturing reduces the amount of plastic waste that ends up in landfills. By using these recycled plastics, businesses can help decrease the demand for virgin plastic materials made from oil and natural gas. This can help preserve non-renewable resources, reducing greenhouse gas emissions and carbon footprints to contribute to the fight against climate change.

In terms of benefits for businesses, recycling injected molded plastics, factory scraps, and defective products is one of the extremely efficient methods for cost saving and improved sustainability. In most cases, recycled plastics can directly back to the manufacturing line which has the same formula and ratio. This can allow the manufacturers to reduce the time and cost of acquiring and blending virgin plastics, masterbatches, additives, etc., whereas virgin plastics are mostly more expensive than recycled ones.

Especially for injection molding production recycled plastic is just as durable as new plastic. This makes it a suitable choice for a wide range of applications, not only be used in injection molding but also in blow molding, and extrusion. This gives producers versatile options to use the recycled plastic pellets they obtained from their production wastes.

Does recycled plastic pellets any better than regrinds for injection molding?

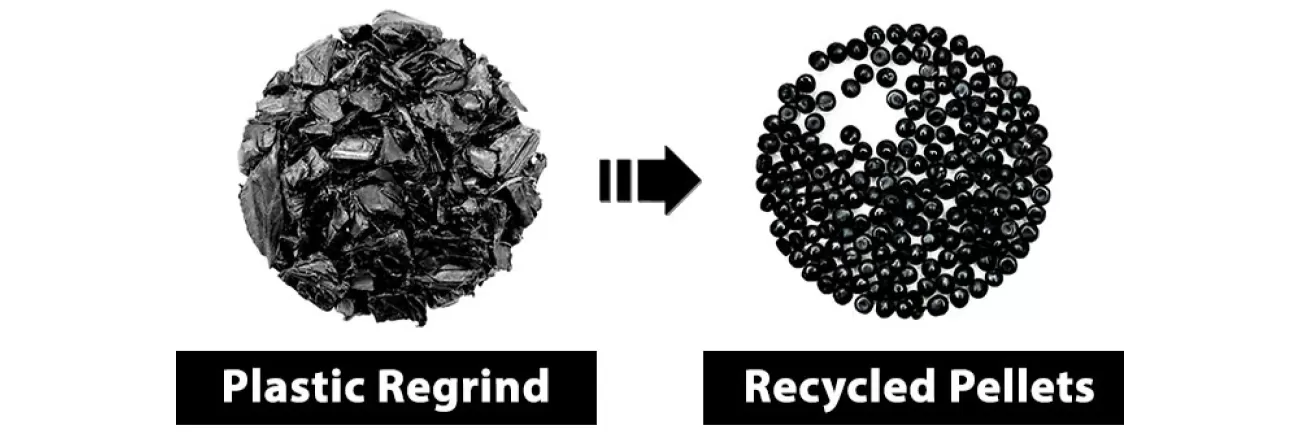

The two most common forms of recycled plastics re-used in injection molding manufacturing are plastic pellets and plastic regrinds. While regrinds are generated by crushing the plastic wastes from injected, blow molded, or extruded plastics; plastic pellets are generated by the plastic recycling machines through melting and reshaping them.

Plastic regrinds come in various shapes and sizes and it is almost impossible to achieve a uniform size and shape. In contrast, the plastic pellets produced by a reliable machine are in uniform sizes and shapes. This makes the plastic pellets superior to plastic regrinds for injection molding manufacturing.

( Recycled plastic pellets provide better melting and mixing features than regrinds )

The key point that makes recycled plastic pellets for injection molding superior to regrind is their shapes and sizes. When the pellet sizes and shapes are uniform, many problems of injection molding caused by regrinds can be solved easily. Such as recycled plastic pellets can mix better with other plastic pellets, masterbatches, and additives evenly and melts evenly.

Key factors why recycled pellets are better than regrinds for injection molding:

-

Better mixing:

Uniform sizes and shapes of recycled pellets help them mix well. -

Better melting:

Heat is homogeneously distributed to the pellets on all sides. -

Even material flow:

Prevents material degradation caused by uneven melting. -

Homogenize product:

Assures final product quality and decreases defect rate. -

Expanding screw and barrel lifespan:

Recycled plastic pellets cause lower wear and tear problems than regrinds.

Plastic recycling machine suggestion for injection molding production wastes

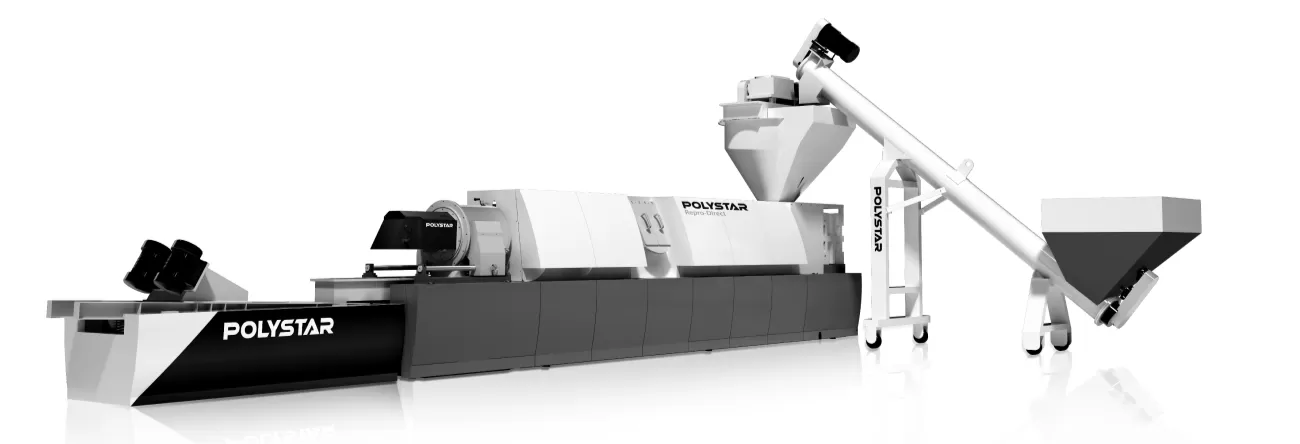

Repro-Direct is a hopper-feeding recycling machine, which is suitable for pre-crushed, heavy, and hard regrinds of injection molded products, plastic bottles, pipes, drums, lumps, etc. Besides, the recycling machine can also process flakes from soft materials such as film, PP raffia, PE/PP woven, and PE foam. It is suitable to process the most commonly used materials in the industry today such as HDPE, LDPE, PE, PP, PA, PC, PU, PBU, and ABS.

How Repro-Direct ensures uniform pellet sizes and shapes?

Repro-Direct plastic recycling machine’s optimized screw & barrel design, double degassing, and dual piston filtration units ensure plastic materials are first evenly mixed and melted, degassed, and filtered in the extrusion process. These optimizations are designed to prevent material degradation (deformation in the chemical structure of the plastic) and increase the output.

Then the plastic melt passes to the die-face cutting pelletizing unit. Here, the pelletizing knives’ speed and their pressure on the die head are automatically adjusted according to the material flow and pressure. Therefore, final recycled pellets result in uniform sizes and shapes. Meanwhile, this automated system prevents material loss, as well as expands die head and pelletizing blade lifespans.

Conclusion

Learn more

- Repro-Direct Regrind Recycling Machine - Machine Info

- Moroccan Biggest Injection Molding Producer recycles with POLYSTAR - Customer Stories

- 5 Tips to Increase Efficiency in Plastic Recycling Process - Blog

About the Author

Resul Gökpınar

International SalesResul creates up-to-date content based on his experience, gained by solving customers' problems in Turkey and the EMEA market.