We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Why Polyethylene Producers Are Embracing Plastic Recycling?

Growing concerns about plastic pollution and its environmental impact have guided global authorities to apply stricter policies on sustainability and circular economy principles. What was once considered optional has now become a necessity.

Polyethylene is the most commonly used plastic polymer for varied applications, such as plastic bags, HDPE bottles, and plastic films. Due to their popularity, polyethylene production was one of the first industries to face these changes. But, how have these new challenges affected polyethylene producers?

Global Trends and Regulations

For instance, some South American clients have expressed they are looking for a recycling machine since their products must contain at least 30% recycled post-consumer pellets before 2030. These regulatory pressures make them actively seek solutions to reduce waste and environmental footprint.

Case Study: Plasticonsumo

Post-Industrial Recycling: A Profitable Strategy

Acquiring a higher-quality plastic recycling machine offers producers several benefits, such as cutting labor costs, space efficiency, and minimizing energy consumption compared to traditional models. If well maintained, plastic recycling machines can last for many years, making them a long-term solution for every plastic producer.

__24K01sUWkB.png)

Mr. Hendrix, Production Manager of the Indonesia-based Plastic Bag Producers

POLYSTAR PE's Recycling Solutions

Before recycling, plastic producers and recyclers must be aware that, as mentioned earlier, polyethylene comes in several shapes and forms since it is the most used plastic polymer. Therefore, they must identify the shape, origin, and percentage of printed surface of their waste before recycling it. Producers and recyclers can choose the appropriate recycling machinery to optimize their operations by understanding these specific characteristics.

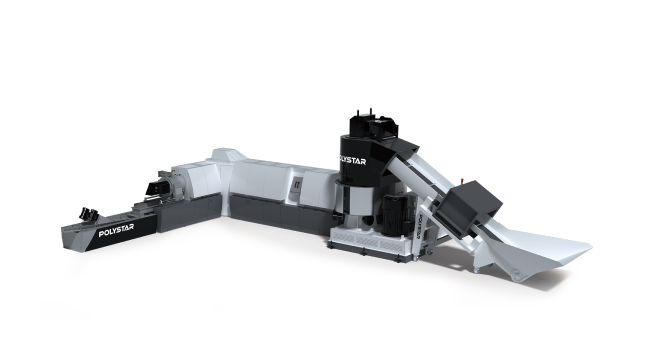

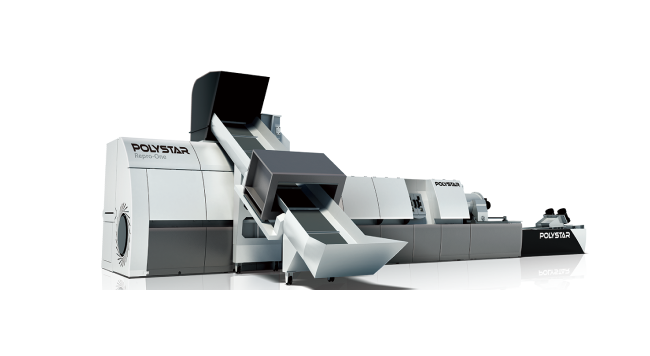

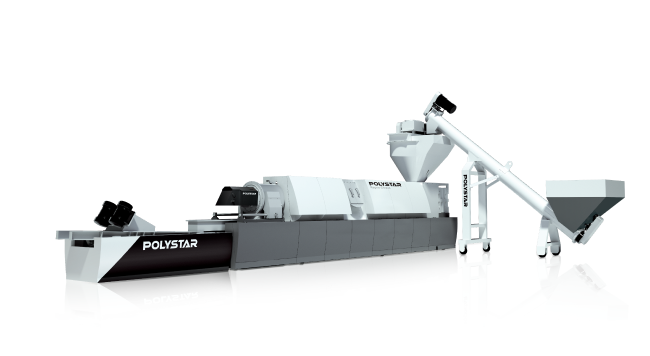

POLYSTAR offers a comprehensive range of recycling solutions to meet each customer's unique needs. Below is a table summarizing which machine can recycle what type of plastic waste (shape and origin).

| Model | Plastic Waste Shape | Origin |

|

Plastic Film Recycling Machine |

Plastic Film, film scrap, bags, bags cut-offs, film-on-rolls, etc.(Printed/Non-printed) |

Post-industrial (factory waste) |

| Washed and dried plastic flakes, multilayer film, plastic film, and scrap | Post-consumer waste |

|

| Plastic lumps or bulks, PE bottles, jumbo bags, woven/non-woven bags, raffia, stretch film rolls | Best for Post-industrial (factory waste) |

|

|

Hard Plastic Recycling Machine |

Hard plastic regrinds, fluffy flakes, washed material, scrap | Post-Industrial & Washed and Dried Post-Consumer waste |

| Plastic Film, film scrap, bags, bags cut-offs, film-on-rolls | Post Industrial Waste - Clean factory waste with no printing |

About the Author

Kevin Umanzor

International SalesKevin advises plastic producers to adopt a circular economy by implementing innovative POLYSTAR machinery. Driven by a commitment to providing the best possible solutions to his clients, Kevin is committed to broadening his learning process by interacting with diverse markets across the globe.