We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Which Plastic Pelletizer System is the Best? A Practical Guide!

There are different pelletizing systems for recycling plastics. Choosing the right one for your next plastic recycling machine is the most important for the materials and final products. Then, let's review which pelletizing system is the best for recycling your plastics?

Strand Pelletizing System

Strand pelletizer is usually used for PET, and materials with high melting index are difficult to process using a water-ring pelletizing system.

In a strand pelletizing system, the plastic melt first passes through a water bath where it is cooled and turned solid. The plastic is then pelletized by air knives, where the water is removed from the surface of the pellets at the same time.

Water-ring Pelletizing System

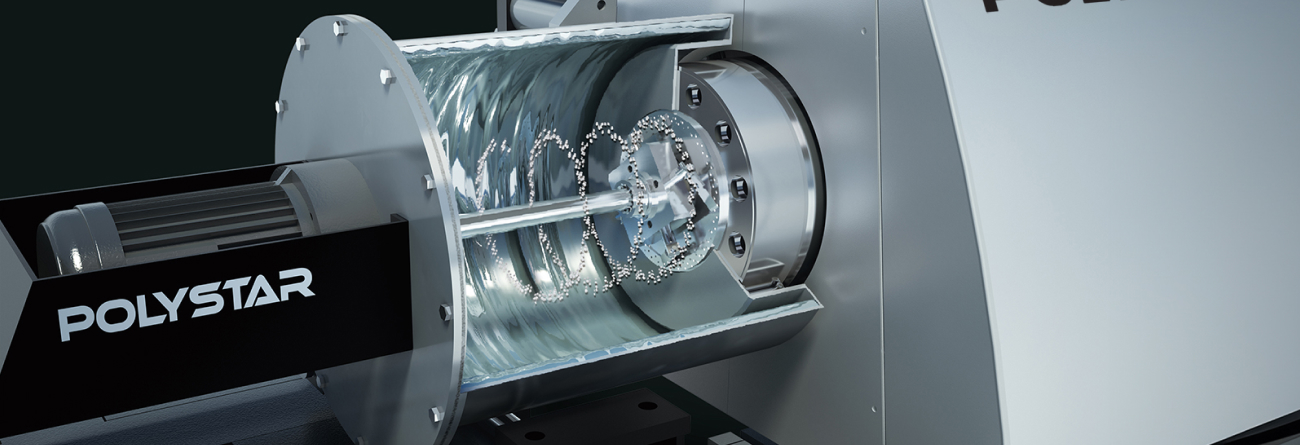

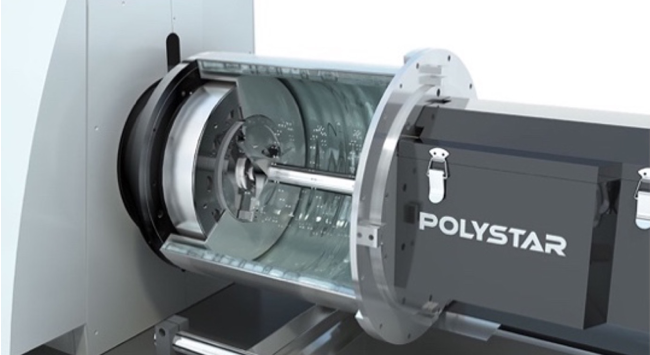

In a water-ring pelletizing system (also known as hot die face pelletizing), the plastic melt coming from the recycling extruder is directly cut by the rotating knives attached to the surface of the die head.

Round-shaped plastic pellets are produced and cooled inside the water ring immediately, flushed out, separated from water on the vibration table, and pass through a centrifugal dryer at the end.

Right Pelletizing System for Reprocessing Plastic Materials Waste

Water-ring pelletizing system has 3 main advantages over strand die pelletizing:

- Easy to operate - machine start-up is faster and requires less operator intervention

- Stable production - continuous running without the risk of strand-breaking

- Simple maintenance - Replacement of pelletizing knife is easy and at a lower cost

For the above reasons, the water ring pelletizing system has been the most popular choice for PE and PP recycling. If you are processing post-industrial or post-consumer film, raffia and regrind - water-ring pelletizing is without a doubt the most recommended and efficient plastic reprocessing system on the market today.

However, if you mainly recycle material with a high melting index, it might be more suitable to go for the strand type pelletizing instead.

About the Author

Jack Lin

Sales ManagerJack has visited and spoken to hundreds of POLYSTAR machine users around the world over the last 10 years. Having collected practical information on customer feedback and user experiences, he enjoys sharing the advantages and disadvantages of using different types of machines with others, especially coming from the customers' perspectives.