We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

What is the Difference Between Post-industrial Plastic Recycling and Post-consumer Plastic Recycling?

When it comes to plastic recycling, there are a few things you should know before deciding on the right machines. There are two types of plastic recycling in general, Post-industrial recycling and Post-consumer recycling. In this article, I will explain the difference between Post-industrial Plastic Recycling and Post-consumer Plastic Recycling.

Plastic waste generated during an industrial process is referred to as "Post-industrial plastic." Internal reprocessing of post-industrial plastic is sometimes referred to as "In-house recycling" or "Factory waste recycling." Whereas Plastic waste that is recycled after it has been used by consumers is referred to as "Post-consumer recycling."

Here are the major differences between Post-industrial recycling and Post-consumer plastic recycling:

- Post-consumer plastic is a combination of a wide variety of plastics that must be sorted before the recycling process, while recycling post-industrial plastics however, producers have the advantage that the input waste type is known and controllable.

- Even post-consumer plastics that are sorted into consistent types may have variations in plastic composition due to the different types of proportions used by various plastics product producers.

- Post-consumer plastics must be sufficiently cleaned with a washing line and control the moisture content under a certain level so that the output pellets can be used to produce new products of acceptable quality.

Post-industrial recycling

( Post-industrial plastic waste )

There is a lot of plastic waste generated during the manufacturing process of plastic products. These wastes are often clean and without any contamination, it would be a shame if they ended up in landfills. If the producers can recycle their own factory wastes and reuse them back in their production lines, they will not only help the environment but also save more costs, which is why post-industrial recycling has become a trend among plastic product producers.

The advantage of using recycling machines from POLYSTAR to recycle post-industrial waste is that the refeeding rate back to the production line is up to 100%, which means less amount of raw material needs to be used in your production process.

Perfect models for Post-industrial recycling: Repro-Air & Repro-Flex

Repro-Air

POLYSTAR's Repro-Air is an Air-cooled PE Plastic Recycling Machine. This compact pelletizing machine is simple to operate and can be placed right next to your production lines such as blown film machines and bag-making machines.

Repro-Air is specially designed for blown film and cast film producers. The model can effectively recycle HDPE, LDPE, LLDPE film scraps (mono and multi-layer), start-up or changeover film rolls (film-on-roll), edge-trim waste, and T-shirt bags bundles (cut-offs) from in-house production.

Key benefits of Repro-Air:

More recycled pellets can be used in production while maintaining the same quality as virgin material.The output pellets will not come into contact with water, thus they will be less contaminated.An energy-efficient recycling machine that uses only 19 kW of power.

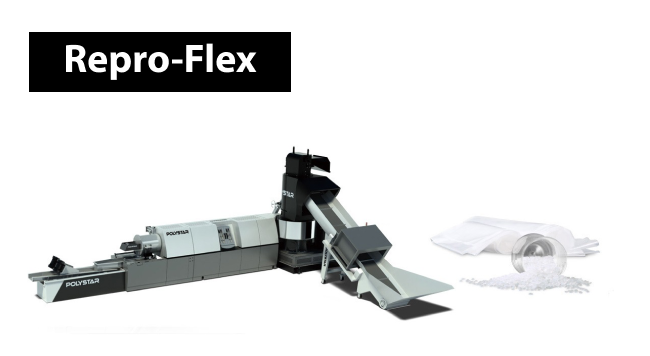

Repro-Flex

Repro-Flex is a cutter compactor integrated recycling machine designed for the reprocessing PE (HDPE, LDPE, LLDPE) and PP materials. It is a compact and efficient recycling machine that combines cutting, extrusion, and pelletizing.

The recycling machine's cutter compactor prepares (pre-conditions) the material for the extrusion process and feeds it directly into the extruder using centrifugal force. In comparison to traditional recycling machines, this integrated system does not require a separate crusher, which eliminates the issue of inconsistent feeding.

Key benefits of Repro-Flex:

1. Easy material feeding without the need for pre-cutting.

2. Higher output capacity compared to Repro-Air, the largest size of this model can reach 1,000 kg/hr output.

3. Wider range of materials can be reprocessed by this model.

Post-consumer recycling

( Post-Consumer plastic waste )

Post-consumer recycled materials, often referred to as PCR, are reprocessed plastics from household or commercial waste. Post-consumer plastic products close the loop by diverting waste from landfills and allowing it to be recycled into something else. Unfortunately, it is difficult to recycle post-consumer plastic. There are financial concerns (collection, cleaning, sorting, reprocessing, distribution) as well as physical issues (color and grade irregularity, contamination). After the wastes are recycled, the plastic pellets will be manufactured into various recycled products according to different physical properties.

POLYSTAR has long been involved in post-consumer recycling, turning plastic waste into new sustainable products. Wide-ranging experience has already been gained in collaboration with third-party filtration manufacturers, and we have successfully assisted many post-consumer recyclers around the world to stay competitive in their markets.

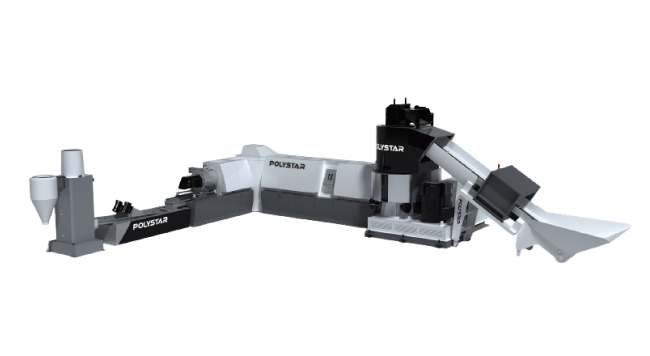

Perfect models for Post-Consumer Recycling: Repro-Flex Plus

Repro-Flex Plus is integrated with a cutter compactor just like Repro-Flex. This model, on the other hand, has an additional extruder as well as three degassing zones and two filtration units. It is designed specifically for processing post-consumer plastic wastes, and it ensures the minimal degradation of the material, resulting in uniform pellets that may be reprocessed right into your production line.

Filtration before degassing is also a unique design for Repro-Flex Plus. It has a better effect on producing excellent quality pellets from post-consumer waste. Furthermore, the second extruder features a third degassing system for removing even more ink and moisture from the materials.

With all the features on Repro-Flex Plus, customers can simply achieve 10% less power consumption; 20% higher output; and 100% pellet re-usability using this model to recycle post-consumer wastes.

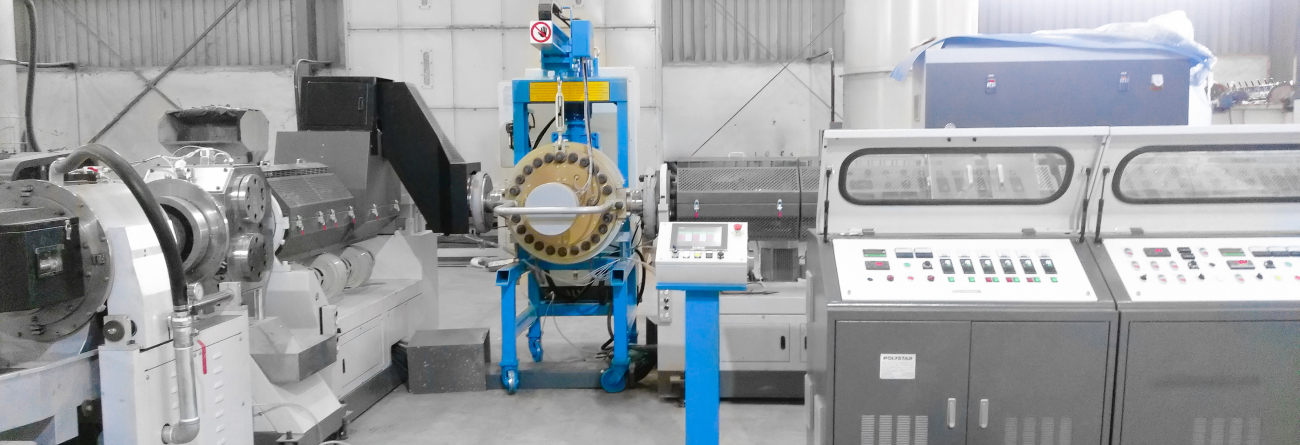

Third-Party Filtration System Integration

POLYSTAR has collaborated with several filtration system manufacturers to provide customers with the best post-consumer waste processing solution. Repro-Flex Plus is extremely compatible with all the third-party filtration systems you can find on the market today, and we have proven that with this integration, the recycling line will be more flexible while handling different kinds of post-consumer wastes.

It is essential to understand that integrating with an automatic third-party filter is not just a matter of technology and operation – it is a strategic solution. It offers the chance to thoroughly change your production business economic indicators. From the perspective of the plastic recycling competition, this choice is remarkable and allows you to improve your competitiveness.

(FIMIC filtration system)

Conclusion

Related Links

About the Author

Derek Shiao

Derek Shiao is a business development manager at POLYSTAR. He keeps up with the latest trend in the plastic industry and creates content based on his experience offering various solutions to customers.