We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

What is Post-Consumer Recyclable (PCR) Plastics?

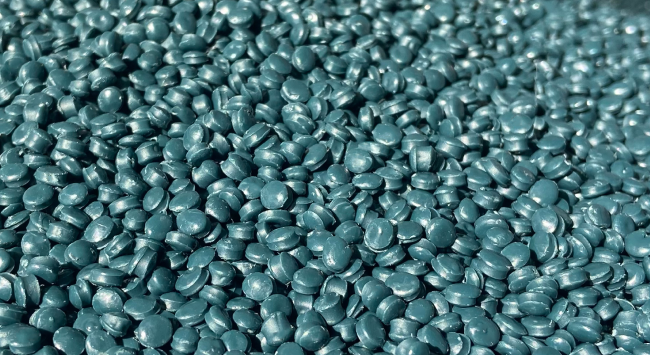

Post-consumer recycled materials, often referred to as PCR, are reprocessed plastics from household or commercial waste. Post-consumer plastic products close the loop by diverting waste from landfills and allowing it to be recycled into something else. Unfortunately, it is difficult to recycle post-consumer plastic. There are financial concerns (collection, cleaning, sorting, reprocessing, distribution) as well as physical issues (color and grade irregularity, contamination). After the wastes are recycled, the plastic pellets will be manufactured into various recycled products according to different physical properties.

( Post-Consumer plastic waste )

What do you need to start your post-consumer recycling business?

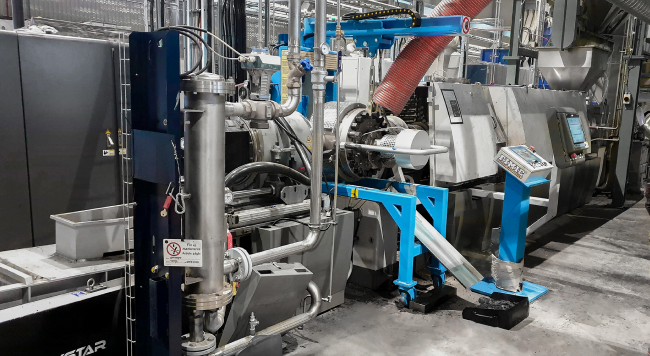

For recycling post-consumer plastic waste, you need a complete sorting, washing, drying, crushing, and pelletizing lines. It is crucial that you control the waste condition before feeding it into any recycling machine. As for the recycling process, the filtration and degassing systems are the critical units to for producing high-quality pellets from post-consumer wastes.

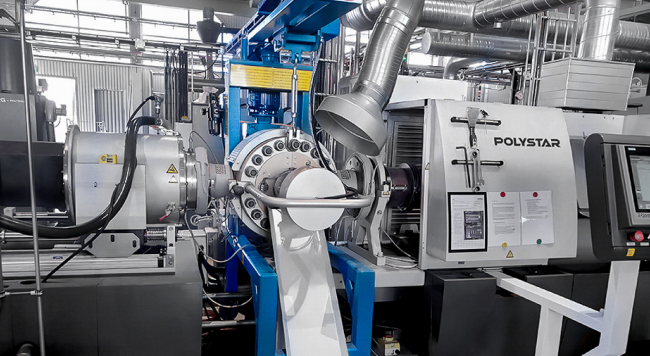

POLYSTAR has long been involved in post-consumer plastic recycling, turning plastic waste into new sustainable products. Wide-ranging experience has already been gained in collaboration with third-party filtration manufacturers, and we have successfully assisted many post-consumer recyclers around the world to stay competitive in their markets.

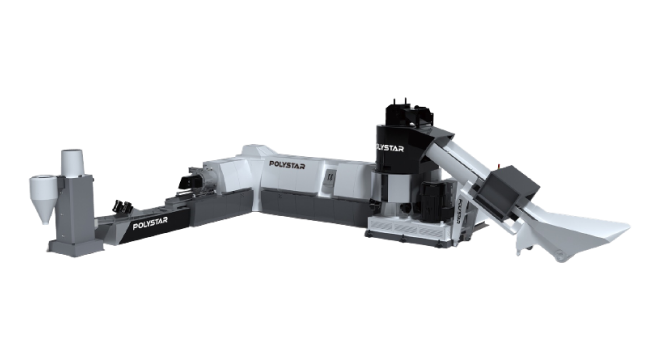

Perfect models for Post-Consumer Recycling: Repro-Flex Plus

Repro-Flex Plus is integrated with a cutter compactor just like Repro-Flex. This model, on the other hand, has an additional extruder as well as three degassing zones and two filtration units. It is designed specifically for processing post-consumer plastic wastes, and it ensures the minimal degradation of the material, resulting in uniform pellets that may be reprocessed right into your production line.

Filtration before degassing is also a unique design for Repro-Flex Plus. It has a better effect on producing excellent quality pellets from post-consumer waste. Furthermore, the second extruder features a third degassing system for removing even more ink and moisture from the materials.

Third-Party Filtration system integration

Conclusion

About the Author

Derek Shiao

Derek Shiao is a business development manager at POLYSTAR. He keeps up with the latest trends in the plastic industry and creates content based on his experience offering various solutions to customers.