We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

What are the Differences Between Single-layer and ABA 3-layer Blown Film Machines?

Single-layer extruder remains the leading trend in plastic bags production

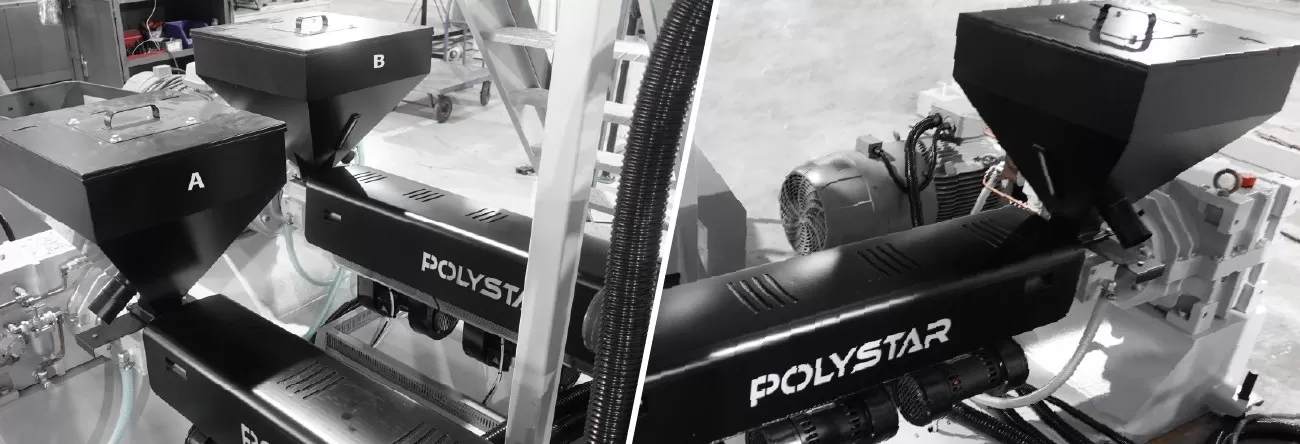

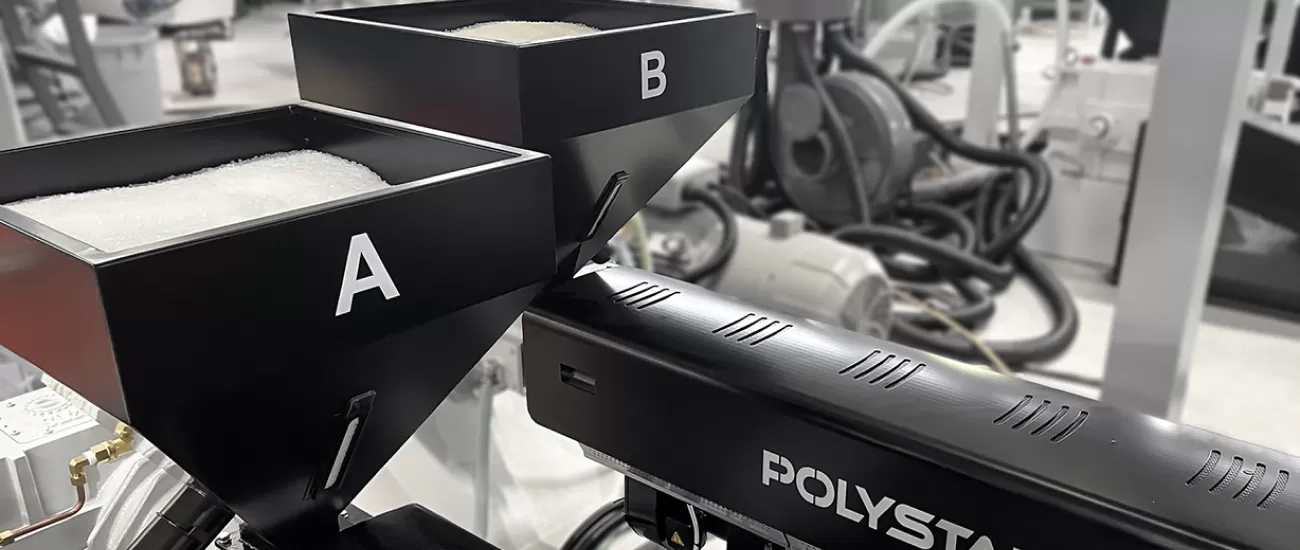

ABA multilayer extruders use more recycling materials

For outer layer A – the producers can put virgin material for the ¬smooth and shining surface, as for the inner surface (B-layer) the recycled materials can be put to enhance the film strength and reduce the production cost. ABA multilayer film-blowing machine is suitable for producing garbage bags, goods packaging (food and beverages), etc.

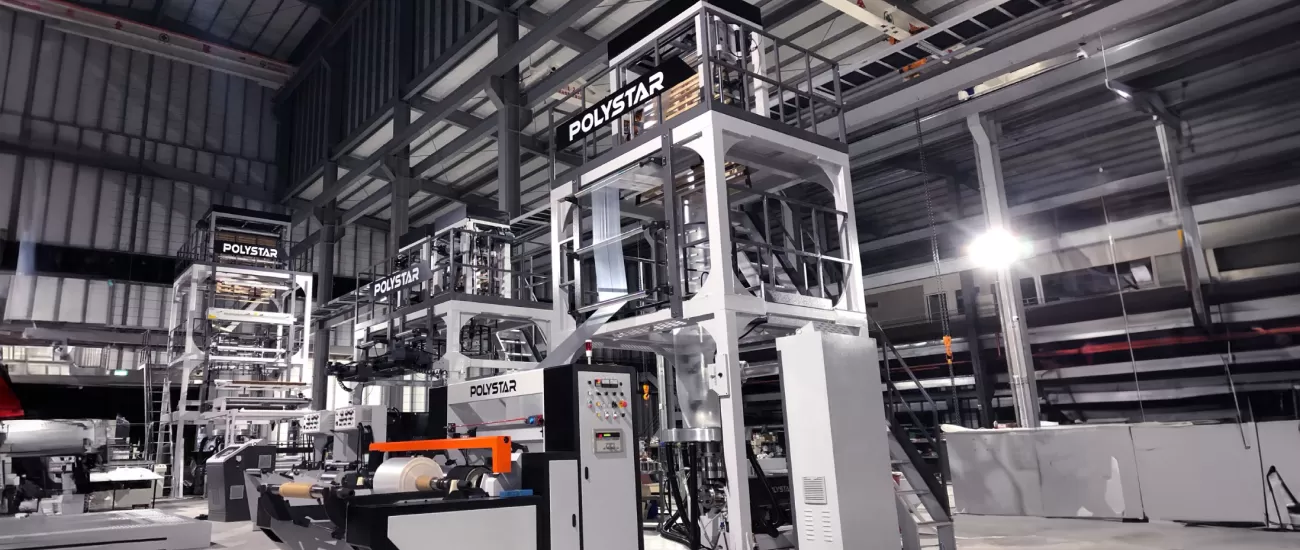

Single-layer and ABA extruder for bag production

Even though a single-layer extruder is efficient for general bag production, an ABA co-extrusion (3 layers) machine has its advantage over one layer machine for certain applications, like garbage bags, shopping bags, and T-shirt bags that are thicker (20 to 100 microns) or require higher film strength. As a result, using ABA multilayer blown film extrusion to produce larger-sized garbage bags has become a new industrial trend in markets like Australia and the UK.

What is the difference between Single-layer and ABA?

| Single extrusion | ABA co-extrusion | |

| Machine cost | Lower | Higher |

| Raw material cost | Higher (Less recycled material can be used) |

Lower (More recycled material/ CaCO3 can be used in production) |

| Produced Film layer | 1 layer | 3 layers (A-B-A) |

| Application | Especially for thinner film (T-shirt bag, shopping bag) |

Produce higher-strength film (Garbage bags, medical bags) |

Learn more

About the Author

Sandy Kuo

E-Marketing SpecialistSandy follows up on the market demand and analysis data in the plastic industry, promoting the brand and doing digital marketing activities by e-commerce.