We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

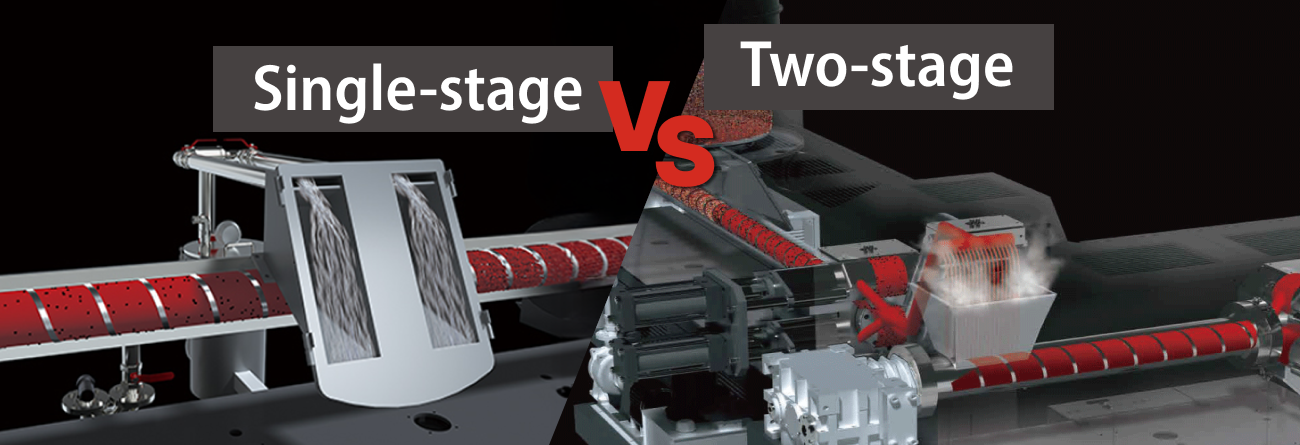

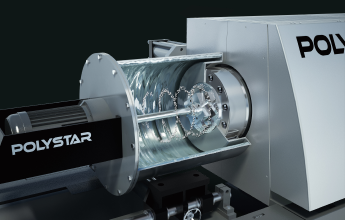

Single-stage vs. Two-stage Recycling Machine

-

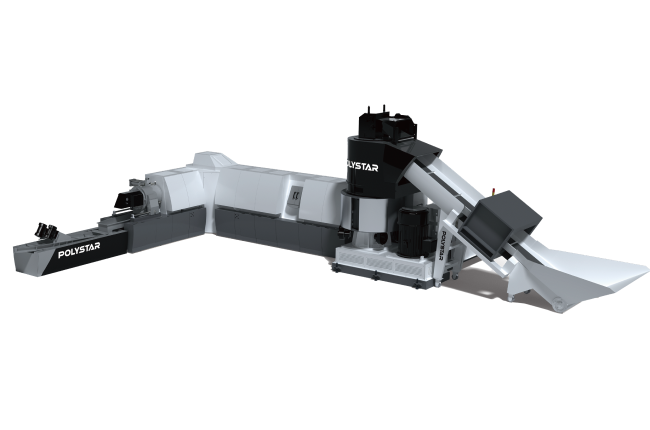

( Repro-Flex )

( Repro-Flex ) -

( Repro-Flex Plus )

( Repro-Flex Plus )

| Repro-Flex | Repro-Flex Plus | |

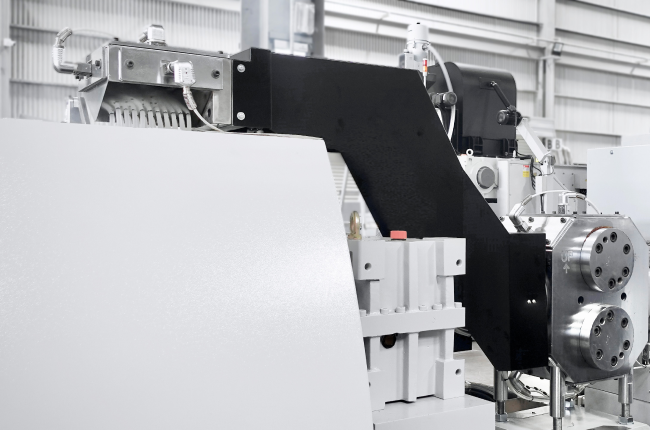

| Number of Extruders | 1 | 2 |

| Number of Degassing | 2 (Double-degassing system) |

3 (Double-degassing system, and one in the venting area) |

| Number of Filtration | 1 (Dual-Piston) |

2 (Dual-Piston and Manual type) |

-

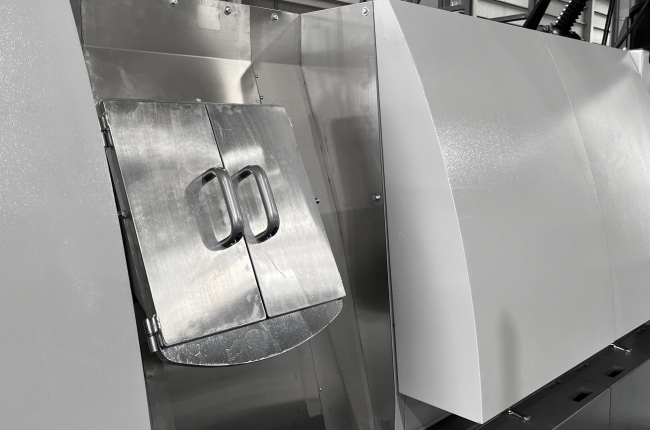

( Double-degassing )

( Double-degassing ) -

( Triple-degassing )

( Triple-degassing )

Same cutting and pelletizing system different materials to reprocess

Repro-Flex is able to reprocess PE and PP films, multi-layered film, stretch films, EPE foam, pre-washed film flakes, non-printed and printed (up to 50%) films, others.

Repro-Flex Plus is able to reprocess the same materials as Repro-Flex but can process highly surface printed material, up to 100% of it. This is able thanks to the reposition of the filter and the third degasification.

These pelletizing machines are highly recommended for packing film producers, blown film producers, PP woven producers and professional recycling centers.

-

(No-printed Film)

(No-printed Film) -

(Printed Film)

(Printed Film)

| Repro-Flex | Repro-Flex Plus | |

| % of Humidity | 3% | 5% |

| % of Surface Print | 50% (Filter Repositioned) |

100% (Filter Repositioned) |

| % of Contamination | Less than 1% | Less than 1% |

( Repro-Flex and Repro-Flex Plus )

Final Product

POLYSTAR recommends

If you are a film producer and you want to recycle your post-industrial waste these two recycling machines are perfect for you. Very easy to install, operate and perform maintenance. Having One-Step direct technology with cutting, extrusion and pelletizing will give your operators a friendly use of it. Remember to have in count the properties of your materials before choosing. If you have any questions or doubts, contact us and we will find a solution to your requirements.

About the Author

Maria Lopez

Marketing ManagerMaria Lopez is a content marketer at POLYSTAR. She authors in-depth guides that provide solutions to Plastic Producers. Not only to select your machine but also to keep you updated with the new trends.