We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Recycled Plastics VS. Virgin Plastics — Which One Fits Your Production?

Plastic products can be produced in different ways, the common-to-see types are blown film, injection molding, blow molding, thermoforming, and rotational molding. Although there are various manufacturing methods, the similarities between those are the quality of the plastic raw materials.

As a result, these essential materials play an important role in the manufacturing process of plastic products, and we can roughly divide these plastic resins into 2 main categories: recycled plastics and virgin plastics, in this blog, we will share what the pros and cons of using recycled plastics and virgin plastics.

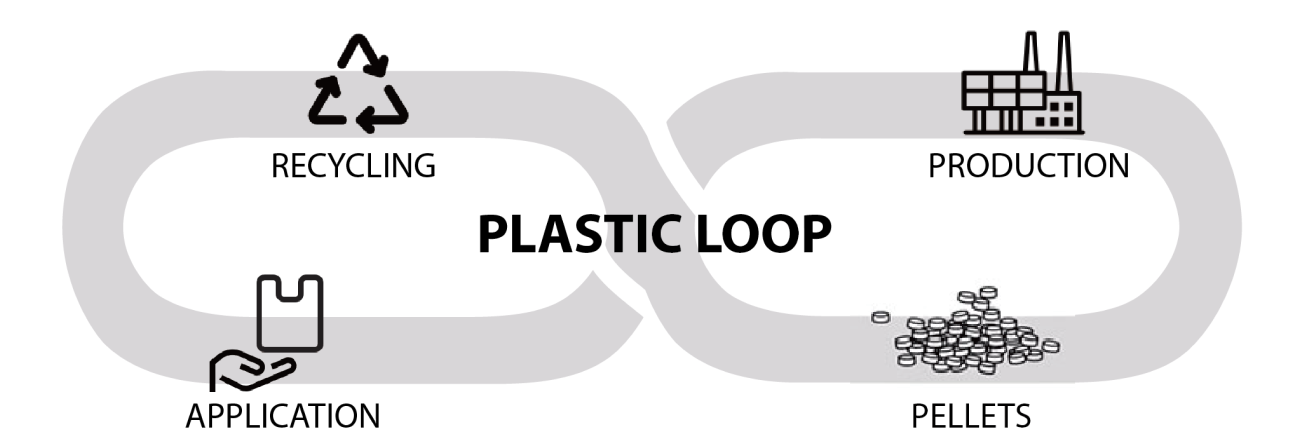

Using recycled plastic to close the plastic loop, what’s more?

With the rise of environmental awareness, many countries are implementing regulations that require a certain percentage of recycled plastics to be used in the production of new products.

For instance, some multilayer plastic film (A-B-A layer) producers start using recycled materials as inner-layer film, while some injection molding procedures are reusing production waste to generate new goods. Using recycled plastic not only can close the plastic loop to remain sustainable but also:

- Reducing carbon footprints and greenhouse emissions

- Cost-saving, for the plastic producer, the in-house recycled pellets can be directly put back into their production line.

- Prevents further pollution, more eco-friendly compared to virgin plastics.

- Can remain the equivalent quality of virgin plastics if using reliable recycling equipment.

( Garbage Bag Made by Recycled Plastics )

Pros and cons table of recycled plastics

While recycled plastics offer numerous benefits when reproducing products, manufacturers must still carefully evaluate whether these recycled plastics are suitable for meeting their product requirements or not. Here we provide some pros and cons of recycled plastics for you:

Pros and Cons Table of Recycled Plastics |

|

| Pros | Cons |

| Cost-saving (Can be down to 0 if collected from the production line) |

Limited availability |

| Lower energy when producing | Takes time to sort before recycling |

| Create circular economy | Might have contamination |

| More environment protection, more eco-friendly | Quality issues if using unreliable machines |

Does using virgin plastic materials always bring benefits?

Virgin plastics are new and pristine materials that are often used to manufacture plastic products such as films and packages. With a sturdier molecular structure, virgin plastics ensure precision and high performance in manufacturing plastic products. However, there are always two sides to every coin, and using virgin materials in your production does not always bring advantages:

- Virgin materials have a high cost

- Generate waste and cause pollution if use-and-throw

- Non-renewable resources which have environmental impacts

- Non-biodegradable characteristics

Pros and cons table of virgin plastics

Pros and Cons Table of Virgin Plastics |

|

| Pros | Cons |

| Pure and clean | Expensive |

| More Durable than reused plastics | Dangerous for the environment |

| Better performance when producing products | End up in a landfill, waste generation |

| Availability for wide applications | Resource-intensive |

* The price of recycled pellets might be different by outsourcing or in-house recycling.

Must-know table: recycled plastic vs. virgin plastic

Must-Know Table: Recycled Plastic vs. Virgin Plastic |

||

| Recycled Plastic | Virgin Plastics | |

| Price | Cost-saving | Expensive |

| Energy to produce | Lower | Up to 3 Times More |

| Life cycle | Create plastic loop | Disposable if not recycled |

| Resources | In-house Production line Outsourcing |

Fossil fuels Natural gas |

| Environmental impact | Reduce the waste ends in landfills | Release Carbon Dioxide when producing Causing Pollution and Climate Change |

Conclusion

Learn more

About the Author

Sandy Kuo

E-Marketing SpecialistSandy follows up on the market demand and analysis data in the plastic industry, promoting the brand and doing digital marketing activities by e-commerce.