We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Recycled Plastic Enhances Sustainability of Blow Molding Manufacturing

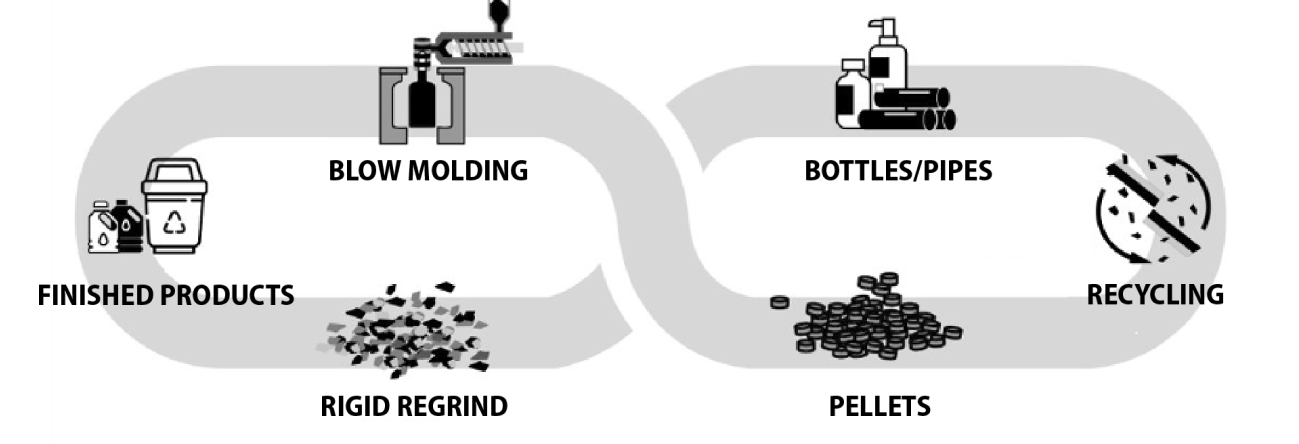

Blow molding plastic manufacturing is one of the most common plastic production methods with a long history. Considering it is one of the most demanding industries for plastic polymers, the economic and environmental sustainability of the industry become a big concern. Using more recycled content in blow molding manufacturing, and recycling blow molded products to circulate the plastic in the industry can significantly ease these concerns.

How the recycled plastic support blow molding manufacturing?

Recycled polymer requires lower energy and releases low carbon. Besides providing a significant environmental benefit, plastic recycling can also support blow molding manufacturing in multiple ways. Using recycled plastic in product content reduces dependency on virgin polymers, which is often relatively more expensive than recycled pellets. Producers can also improve their business reputation since more and more customers become environmentally conscious and support products made from recycled materials.

How to source recycled plastic from blow-molded products?

Recycling blow-molded products and production scraps is as important as using recycled content in production because production scraps are one of the best material sources due to providing recycled plastic for production with the same blend and formulation.

In this way, producers can close the loop of the circular economy, achieve sustainability goals, and reduce costs. We can separate the recycling process into three main steps as below:

1. Sorting based on plastic type and shape

2. Crushing, washing, and drying plastic

3. Plastic Pelletizing

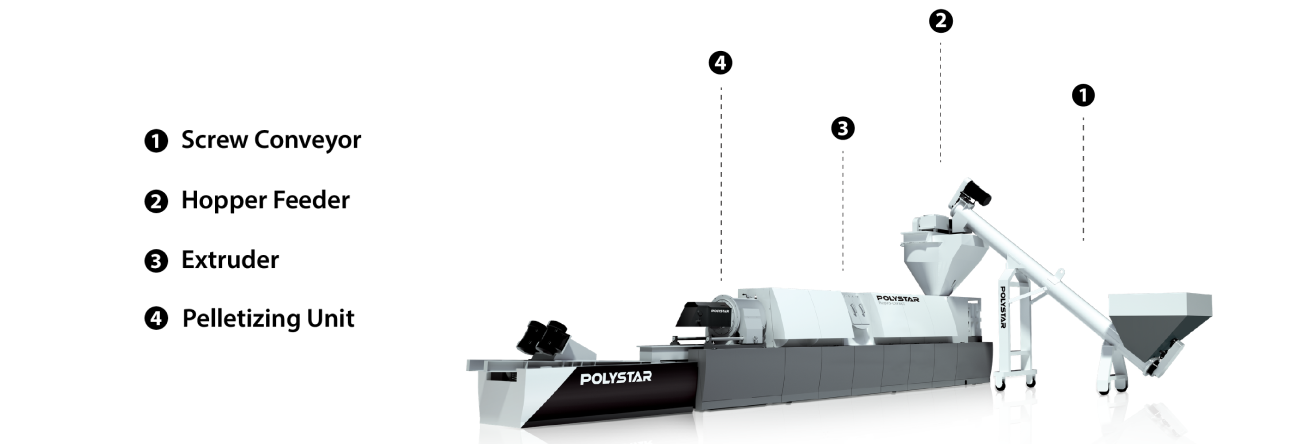

Repro-Direct regrind pelletizer process the materials as follows:

- Plastic regrind feeding to the hopper via screw conveyor or belt conveyor.

- Hopper feeds regrinds to the extruder. A force feeder can be attached to prevent bridging.

- In the extruder, plastic is melted, degassed, and filtered.

- The water ring pelletizer cuts plastic melt into uniform size and shaped plastic pellets.

Where to use recycled blow molding plastics?

As long as meeting the quality and formulation requirements, recycled pellets from blow-molded products can be used in many different plastic manufacturing methods. Most importantly, blow molding manufacturing scraps can be used back in the production lines after being recycled.

In addition to using back in blow molding, the recycled pellets from blow-molded materials can be also used in injection molding, extrusion molding, and blown film lines as recycled content to produce many different plastic products.

The multiple fields of applications and the wide circulation among different industries, allow recycled blow molding plastics to provide a big sustainability advantage to the plastic manufacturers. By recycling production scraps, and using recycled contents in their production, blow molding manufacturers can save costs, stay competitive, and improve their business reputation.

About the Author

Resul Gökpınar

International SalesResul creates up-to-date content based on his experience, gained by solving customers' problems in Turkey and the EMEA market.