We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Quality and Consistency of Output - Plastic Recycling

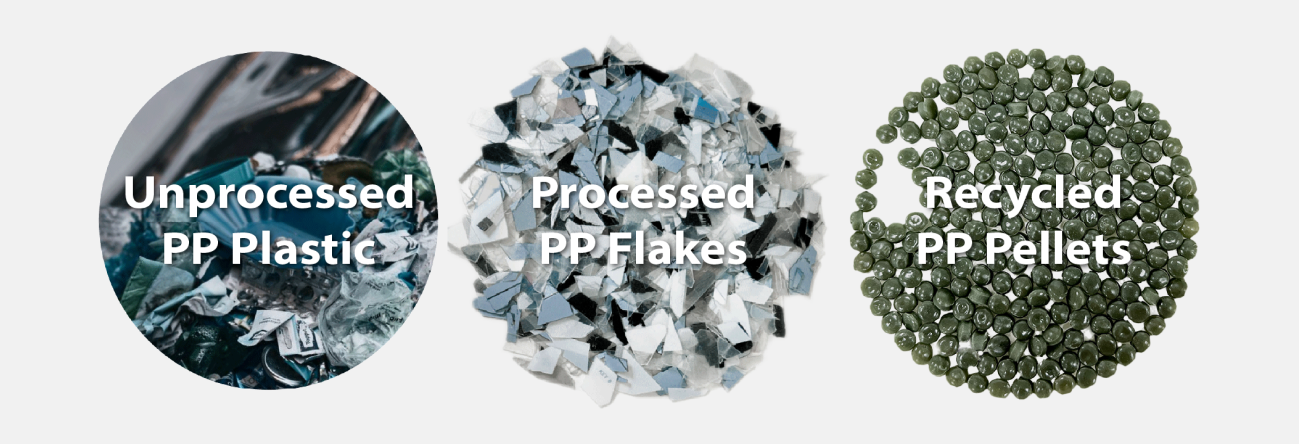

High-quality final pellets coming from well-prepared input material and a well-controlled recycling process is a matter of course. In other words, recycled materials without proper preworks and a recycling process without inspections will not bring you plastic pellets which meet the market standards.

This article aims to help you identify any crucial missing elements in your plastic recycling process and provide suggestions to improve your recycling business.

Why is “consistency” important in plastic recycling?

Consistency is crucial throughout the plastic recycling process, from the quality of the input material to the processing conditions and the output quality of the recycled pellets. Maintaining consistency in these areas helps ensure the efficiency of the recycling process and increases the marketability of the final product.

Tips for the consistent quality of plastic recycling

-

Adequate preparation

To obtain high-quality final pellets, it is essential to ensure that the input material is of the same quality. This means sorting, washing, drying, and crushing should be done to the highest standard.

-

Material testing

Testing before full-scale manufacturing allows for the examination of the material's purity, properties, and shape, as well as for identifying any problems with the recycling machine's operation. It is crucial to monitor the consistency of the output quality and adjust parameters if necessary.

-

Regular inspections and continuous improvements

Consistent quality of the recycling process can be maintained by regularly inspecting the process to identify potential or existing problems, ensuring a smooth procedure. Additionally, reviewing and identifying areas for improvement can help enhance the process further.

How to take plastic recycling to the next level?

-

Integrated plastic recycling technology

The most ideal situation is to produce consistent quality pellets with the least space, costs, and effort.

POLYSTAR’s plastic recycling lines integrate cutting/shredding, extrusion, and pelletizing into one machine, making recycling more convenient and cost-saving. Additionally, feeding, degassing, and filtration systems enhance stability and efficiency, ensuring output quality consistency.

-

The awareness of the latest trends

To remain competitive, it's crucial to stay informed about the latest trends and innovations in the industry. This can be achieved through attending plastic trade fairs, following industry leaders, monitoring your competitors, and other approaches.

Conclusion

About the Author

Janine Cheng

Marketing AssistantJanine creates engaging content for POLYSTAR’s social media presence, including keeping social media channels updated and brand-focused and seeking ways of connecting with plastic producers and recyclers.