We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

POLYSTAR’s Recycling Machines in North America

Managing Director of Tennessee-based recycler, Mr. Irvin Payne, shares his own experience with his POLYSTAR Recycling Machine in North America.by allowing them to lower their costs.

Q : Could you give us your opinion about your POLYSTAR Recycling Machine?

A: My experience in the industry includes installing and operating American and German extruders for over 30 years. In my opinion, POLYSTAR does a very good job in designing and building extruders, and for the price they offer, it cannot be matched. I considered buying a German machine at three times the cost before I decided to buy this POLYSTAR machine.

Q : Which POLYSTAR machine model do you use?

We have run BOPP film with just the shred drum (cutter compactor) at over 1500 lbs/hr. Also, we have added a melt filter (third-party filter) on the line to remove labels, which works well together with our recycling machine from POLYSTAR. If you will be processing your own in-house waste film, you won’t need a melt filter. You only need one if you were to use post-consumer waste or recycled content back into the film you produce.

Q : Does the real output compare to the nameplate output?

A : We can't run the line at the 1700 lbs/hr nameplate, but we can run it over 1600 lbs/hr with some materials depending on the material’s density. The bulk density usually depends on the screen size in a normal shredder. In a cutter compactor, the hardness of the material and the condition of the blades determine how finely the material is shredded and how tightly the shredded material is transferred to the screw. That’s why you will find that LLDPE film processes a little slower than LDPE film. In my recycling line, BOPP film runs at 1500 lbs/hr yield as it has a cutter compactor with a sharp blade.

A : Determining the ratio is part of the learning curve with the cutter compactor. With ours (it may or may not apply to yours), we found that we can run the cutter compactor at high temperatures to increase the rate and use the water injection system to prevent the plastic inside the compactor from completely melting. Once operators have experience in doing this, they become very adept at keeping the rate. The double vacuum degassing system removes water from the plastic melt very effectively, so when processing post-consumer LDPE we can always wet-treat the material. Actually, we used wet PP today and it worked well with the double-degassing system. If you process printed film, I would definitely recommend the double-degassing unit.

With a compactor, the rate at which you feed it is everything. Overfeeding the compactor or feeding it at a high-rate variation will cause problems. First, the line operators learn how to feed the line at a steady rate, then they learn their other tasks. We currently run PP bags at 1400 lbs/hr and the extruder is rated at 1500 lbs/hr for PP. Again, this is a learning experience, to achieve optimal rate, our average rate is probably 20% lower than the instantaneous rate due to operational issues such as screen changes and other operational issues. Our average rate for PP bags is about 1200 lbs/hr.

As you probably know, an extrusion process is managed through first pass yield (good product processed/ total product processed), utilization (uptime as a percent of scheduled hours), and rate (% of achievable nameplate based on the material). The product of these three metrics is the efficiency percentage. We strive for 95% first pass yield, 95% utilization, and 95% rate. The product of the three metrics is 86% Efficiency. This is challenging but very profitable if you can achieve it.

Q : Are you pleased with the Recycling Machine’s performance?

A : Very pleased. I am quoting another line with POLYSTAR with a few modifications so I can add more recycled materials.

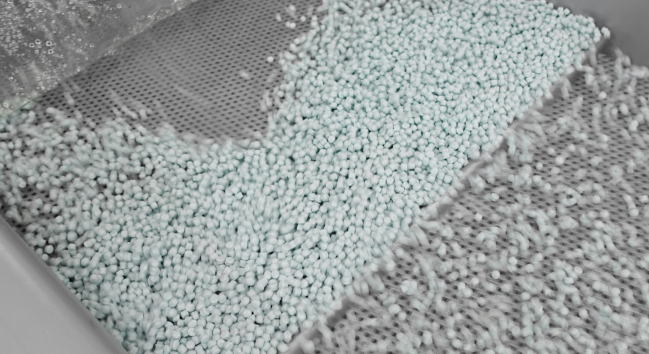

Q : How’s the quality of the output pellets produced by your POLYSTAR pelletizer?

A : The pellets we produce are of the highest quality and our customers love them. The double degassing (vacuum) system really makes a difference in the quality of the pellet.

Q : How’s the quality of the POLYSTAR machine?

A : I recommend you install the best water-cooling system you can (we use a cooling tower but you may need a chiller) and a very good filtration system for the water to remove pellets and fines. If you don’t have proper cooling and filtration, the extrusion system will become contaminated and this will affect the operation of the extruder. With the right design, the extruder will operate without problems.

I do not think anyone will regret buying a POLYSTAR line. I am available to talk to potential customers and welcome a visit from any potential customer who wants to see a line in operation or perform a trial. We are happy to show it off.

We’ll help you to find a simple solution for your plastic waste.

Learn More

About the Author

Derek Shiao

Derek Shiao is a business development manager at POLYSTAR. He keeps up with the latest trend in the plastic industry and creates content based on his experience offering various solutions to customers.