We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Renee Castro

-

Maximize Plastic Film Sheet Production with One Machine

Choosing the right size of blown film machine is crucial when planning your production, and a key factor in doing so is the maximum width of the film you will produce. However, if your goal is to produce narrow plastic film sheets, we have a clever strategy to help you maximize your output.

Read Article > -

Recycled Materials as a Key Element for Blown Film Extrusion in Latin America

With the increased adoption of sustainable processes and changing industry regulations, more producers are choosing POLYSTAR machines to align their products with market requirements. POLYSTAR has become a reliable partner for producers and recyclers of post-industrial and post-consumer waste...

Read Article >

-

What are the Types of Plastic Mechanical Recycling?

Mechanical recycling refers to the process of recovering plastic materials through sorting, shredding, washing, drying, and pelletizing. Depending on the type of plastic waste to be recycled and its condition, this process can be adjusted and even shortened, helping streamline recycling operations...

Read Article > -

Exploring Recycling Materials and New End Product Possibilities

With consumers increasingly pushing for less raw material usage, the last few years have exhibited an increase in recycled plastics as basic materials for production, helping repurpose products that otherwise would be considered waste. But what type of plastic materials can be recycled? How can plastics be recycled? And what end products can be made using recycled materials?

Read Article >

-

How to Produce a 3-Color Plastic Film?

Extruding plastic of different colors into a single film is quite popular for applications such as t-shirt bags, sufra film, or ribbons, where the attractive colors can create a significant increase in the product’s demand in comparison with other products using a single color. In this blog, we will explain how to produce this appealing tricolor striped plastic film.

Read Article > -

Cost-Saving and Friendly Operation Plastic Recycling Machines

Having a recycling machine in your production facility not only helps the environment but can also help you cut costs, but before choosing a recycling machine you must make sure that this works well according to your needs. In this blog, we will explain some important factors to keep in mind before choosing a plastic pelletizer.

Read Article >

-

Material Handling and Feed Systems for Plastic Recycling Machines

By optimizing the handling and feeding of plastic waste with systems like belt conveyors, screw conveyors, and nip rollers, you can improve the efficiency of plastic recycling machines and ultimately reduce costs. In this blog post, we'll explore the importance of material handling and feeding systems for plastic recycling machines and take a closer look at how they can help make your recycling operations run smoothly.

Read Article > -

Common Uses for 1-Layer Blown Film Machines in the Plastic Industry

One-layer blown film machines have become a crucial part of the plastic industry. Film produced with these machines is a versatile and cost-effective solution for applications from food packaging to bags of different types. Here, we will discuss the most common uses of one-layer blown film machines and the advantages of using each type for different applications.

Read Article >

-

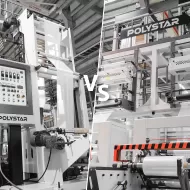

How to Choose the Right Blown Film Machine for Making Small Plastic Bags?

Producing film rolls of smaller width can be an easy way for producers who are new in the business to begin their production. Sizes under 800mm are also very common for producers who start to switch their bag production from outsourced into in-house. POLYSTAR offers different machine types to choose from. Producers can choose between...

Read Article > -

3 Benefits of Using a Gravimetric Dosing Device for Monolayer Extrusion

Lately, more monolayer film producers have begun to add gravimetric dosing devices to their blown film machine lines, getting an advantage over their competitors by allowing them to lower their costs. Here we explained 3 benefits of using a gravimetric dosing device for monolayer extrusion.

Read Article >

-

Why Should All Plastic Film Producers Recycle?

Although plastic is a very popular material, on a global level, less than 10% of it is recycled. With plastic waste being in such a high supply, producers could benefit from incorporating recycling into their existing business model. In this blog, we will share how you can benefit from plastic recycling and what equipment you need to make your plastic film more eco-friendly.

Read Article > -

Plastic Recycling Machines