We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Jack Lin

-

Film Extruder with Twin Head – Efficient For Bag Production?

Compared to extruders with single-die heads, double-die extruders can achieve higher production capacity when producing film rolls that are small in width... -

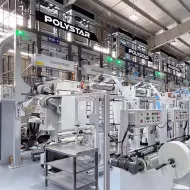

POLYSTAR Simple Solution for Post-consumer Recycling

The POLYSTAR extruder pelletizer and FIMIC filtration system combination provide professional recyclers with a simple, cost-effective solution that has a much lower operation and maintenance cost, which results in...

Read Article >

-

Recycling for Post-consumer and Post-industrial Plastics on the Rise

With the great importance of recycled-based plastic products, the global demand for plastic recycling is expanding. Recyclers are now purchasing more advanced technologies...

Read Article > -

Which Plastic Pelletizer System is the Best? A Practical Guide!

Choosing the right pelletizing machine for your next plastic recycling machine is the most important for the materials and final products. Then, let's review which pelletizing system is the best for recycling your plastics?

Read Article >

-

How Does Squeezer Dryer Improve Post-consumer Plastic Film Recycling?

In post-consumer plastic recycling, pre-washed film waste coming directly from the washing line contains a very high percentage of moisture that is difficult to reduce using traditional drying machines. One of the better solutions...

Read Article > -

Co-extrusion AB and ABA Blown Film Machine - A Simple Comparison

Both AB and ABA co-extrusion blown film machines consist of 2 extruders, the main difference between the two is the design of the material flow channels in the die head. In this blog, we will learn more about and make a comparison of these two co-extruders.

Read Article >

-

3 Benefits You Must Know About In-house Plastic Recycling

In this article, we will share the main reasons why you should start in-house recycling instead of outsourcing. The reasons are based on the aspects of product quality, production costs, and...

Read Article > -

3 Reasons Mini Blown Film Machine is Good for Plastic Bag Making

Mini-type blown film machine is a very popular model for t-shirt bag and flat bag producers. The common screw sizes are Ø40mm, Ø45 and Ø 55mm which cover...

-

Recycling - Bigger Pelletizing Extruders in High Demand

With the great importance of recycled-based products for both rigid and flexible packaging, the global demand for plastic recycling is expanding. Recyclers are now purchasing much plastic equipment at once, as well as the bigger pelletizing extruders.

Read Article > -

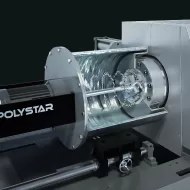

2 Reasons Why Air-cooled Recycling Extruder Can be Better than Water-cooled Pelletizing?

A water-cooled recycling extruder is the most common recycling machine in the market for both post-industrial and post-consumer recycling. However, the air-cooled recycling pelletizer can be the better option sometimes, especially...

Read Article >

-

Recycling Machine Sales Doubled for POLYSTAR in 2021!

The growing demand for plastic recycling directly reflects the machine sales for POLYSTAR. By the end of April 2022, a total of over 110 recycling machines will have been shipped within 12 months – twice as many compared to last year...

-

Recycled Plastic Pellets from PP Raffia and Woven Production – Tips to Reuse them Better

On average, 5-10% of production waste is generated during the PP woven bag-making process at different stages of the production. Here we have some tips to reuse recycled plastic pellets from PP raffia and woven production better.

Read Article >

-

Bulk Bag Recycling - Which recycling machine to buy?

In most cases, producers can use up to 100% of recycled pellets from production waste such as pp raffia, pp bag, bulk bag, and endless tape, while still able to maintaining the strength and quality of the end product (woven bags). The following factors...

-

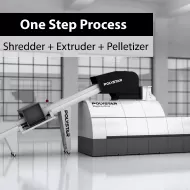

300th Shredder - Plastic Recycling Machine goes to India

The Repro-One 85 is the 300th all-in-one (shredder + extruder + pelletizer) plastic recycling machine that POLYSTAR has sold worldwide. This shredder integrated recycling line is on the way to India and will be in operation before July 2021.

Read Article >

Plastic Recycling Machines

__24F265QXUA.webp)