We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

What is Polyethylene Used for? – Polyethylene Plastic Cycle in the Circular Economy

In this blog, we will explore the common uses of polyethylene and its sustainable cycle in the circular economy.

What is Polyethylene Plastic?

Benefits of Polyethylene Plastic

- Lightweight yet strong,

- Flexible and easy to mold and shape,

- Durable and has a longer life span,

- Resistance to chemicals and moisture,

- Recyclable and its derivatives can be blended.

When all put together, these make PE an outstanding and affordable material for wide use in plastic applications.

Applications of Polyethylene Plastic

The versatility and superior benefits of polyethylene mentioned above make it a highly preferable material, especially for packaging, agricultural, transportation, construction, and consumer goods applications. Some of the specific applications made by polyethylene and its derivatives can be listed as:

- Packaging (plastic films, bags, drums, bottles)

- Agriculture (mulch films, greenhouse films)

- Transportation (stretch and shrink wraps, crates)

- Construction (pipes, tubing, geomembranes)

- Consumer goods (toys, household containers, plastic furniture)

Furthermore, thanks to the easy-to-mold and shape feature of polyethylene, several plastic molding and processing methods are used to produce PE applications. One of the most common production methods is the PE-blown film extrusion method for producing soft-flexible film materials for a wide range of applications from plastic shopping bags, film wraps to agricultural films.

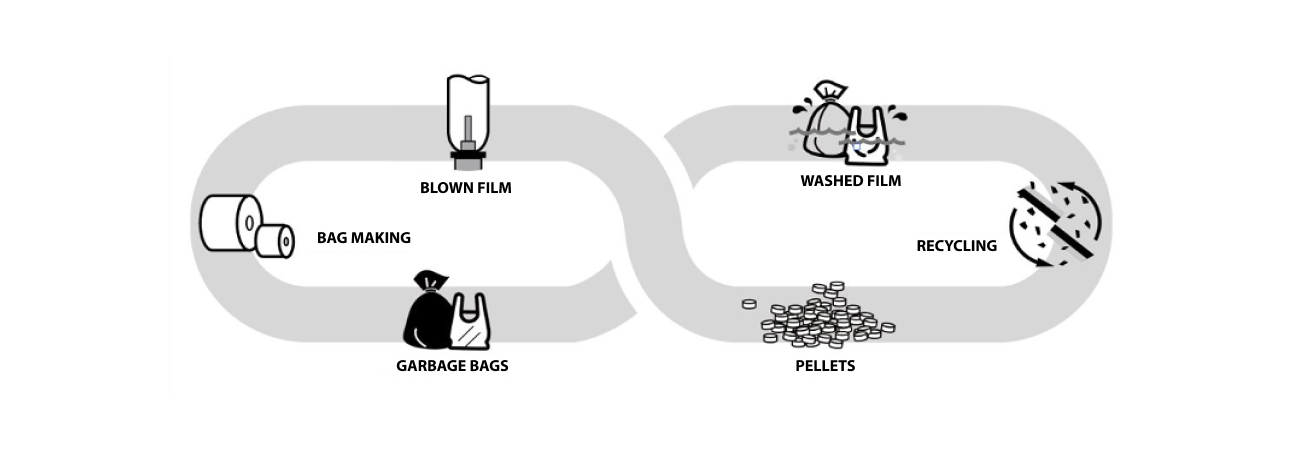

Polyethylene in the Circular Economy

Polyethylene is highly recyclable and the recycled polyethylene can be used several times for manufacturing certain products, and/or used in the resin mixture to reduce the cost of the plastic products manufactured. This not only reduces our dependency on virgin polymers and reduces environmental impact, but also reduces production costs for the manufacturers and provides them a competitive advantage.

About the Author

Resul Gökpınar

International SalesResul creates up-to-date content based on his experience, gained by solving customers' problems in Türkiye and the EMEA market.