We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

How is Plastic Recycled? Streamlined Plastic Recycling Process

In response to the emerging demand for the recycling of plastic wastes such as PP raffia, woven and rigid plastics, POLYSTAR has developed the shredder integrated plastic granulator for plastic producers and recyclers. It aims to provide a simple plastic recycling process to help producers to complete their circular economy cycle.

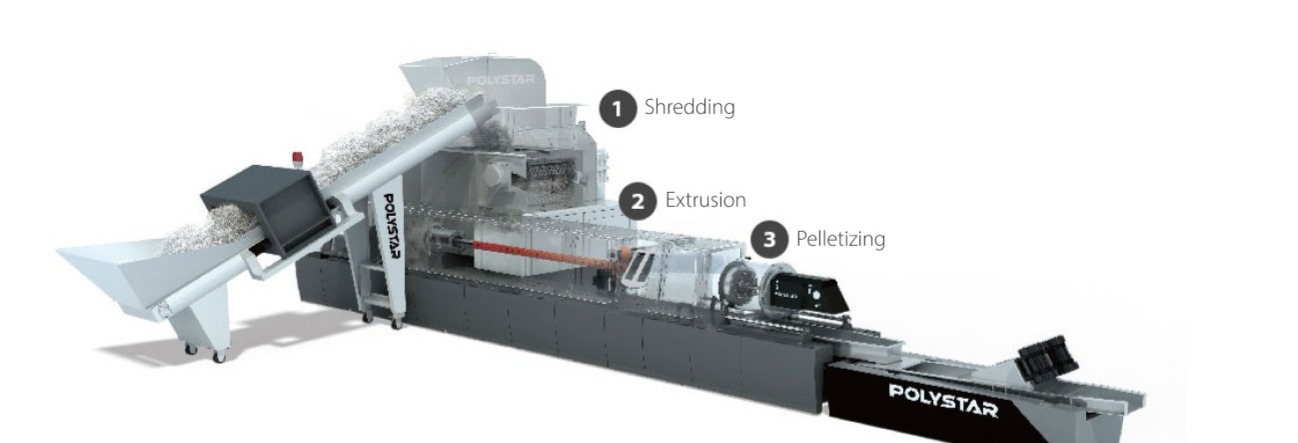

Repro-One plastic granulator is highly flexible with the integration of intelligent systems to increase process automation. Besides it combines three main plastic recycling processes into one single machine (Shredding + Extrusion + Pelletizing).

1. Shredding Process

Generally, hard-to-crush and bigger-sized waste plastics are first pre-crushed with plastic crushing machines. In contrast, with the Repro-One shredder integrated plastic granulator, the materials can be directly fed into the machine without pre-crushing.

Just after the shredding process with the single shaft shredder, the materials are immediately transferred to the recycling extruder. Thus, consistent feeding, which is one of the prerequisites for a higher output, is easier to achieve.

2. Plastic Extrusion Process - Efficient Degassing and Filtration

Degassing unit

The humidity and ink especially the printed and humid materials contained, turn into gas in the plasticization. Effective degassing for such materials prevents air bubble formation inside the final pellets.

The optimal screw design and the double-vented degasification together eliminate the problem of material leakage from the ventilation window. Thus, the machine can work at full speed.

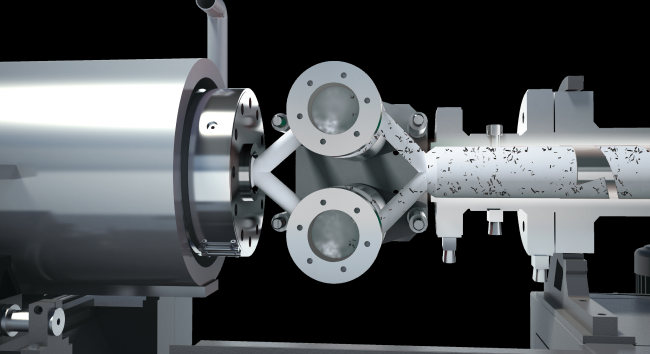

Filtration unit

Dual-piston filter system allows filter screen changing while the machine is running and prevents material waste. Avoiding loss of time and efficiency caused by machine downtime.

In order to further increase automation in the recycling process, we have also been offered a back-flush filter system that automatically performs melt waste discharging and reduces the cost of screen replacement operation.

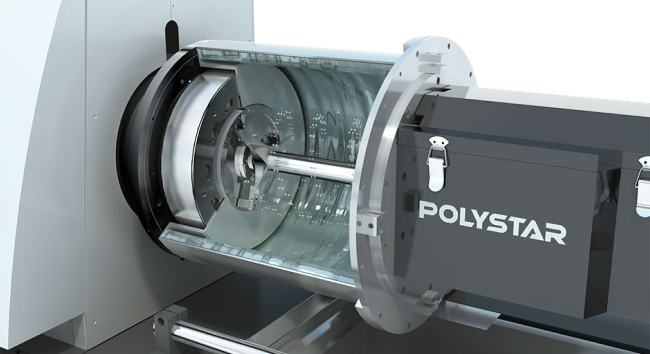

3. Pelletizing Process – Uniform Sized Pellets

Automatic pelletizing knife speed adjustment

Automatic pelletizing knife pressure adjustment

Plastic Recycling Process Automation with Intelligent Systems

Regarding to the circular economy sustainability, Repro-One shredder integrated plastic granulator machine is designed for producing high-reusability pellets with uninterrupted operation. For that, the plastic granulator not only combines shredding, extrusion, and pelletizing processes into a single machine but also ensures these systems work in harmony through automation systems.

In addition, the material feeding speed to the shredder is also automatically controlled. It results in consistent feeding for higher pellet output.

( PLC Control System )

In accordance with the development of Industry 4.0, customers can also upgrade the standard control panel to the PLC control system. This system has a user-friendly HMI (Human-Machine Interface), which significantly shortens the learning curve for operators. PLC control system can perform many different tasks including online troubleshooting, big data collection and analysis, automatic pre-heating, and parameter optimization with cloud IP control.

Conclusion

As global environmental protection awareness continues to grow, circular economy sustainability is becoming a very important trend in the sector. Recycling is an important part of this cycle and should be encouraged more. POLYSTAR therefore designs not only efficient and energy-saving machines but also plastic granulators that are easy to use and can process a wide range of plastic materials.

For this reason, Repro-One shredder integrated plastic granulator is especially preferred by our customers who want to recycle different materials such as PP raffia, woven, jumbo bags, films, start-up lumps, uncrushed hard plastics, and many in one step. You can also contact us to get more information about plastic granulators and find a suitable one for yourself.

About the Author

Resul Gökpınar

International SalesResul creates up-to-date content based on his experience, gained by solving customers' problems in Turkey and the EMEA market.