We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Plastic Recycling Machines - Does Your Factory Have the Right Solution for Recycling Your Materials?

Producers understand the relevance of recycling the plastic waste created by their facilities. The shortage of resins drove plastic producers to respond faster and take action to recycle their factory waste, and thus to explore innovative ways to recycle post-consumer waste. This is possible with the right solutions for each factory and reliable plastic recycling machines.

Recycling with easy operation and maintenance

Plastic materials such as polyethylene and polypropylene are produced and reproduced in the plastic industry. Producers are striving for a complete circular economy process in order to save money and protect the environment.

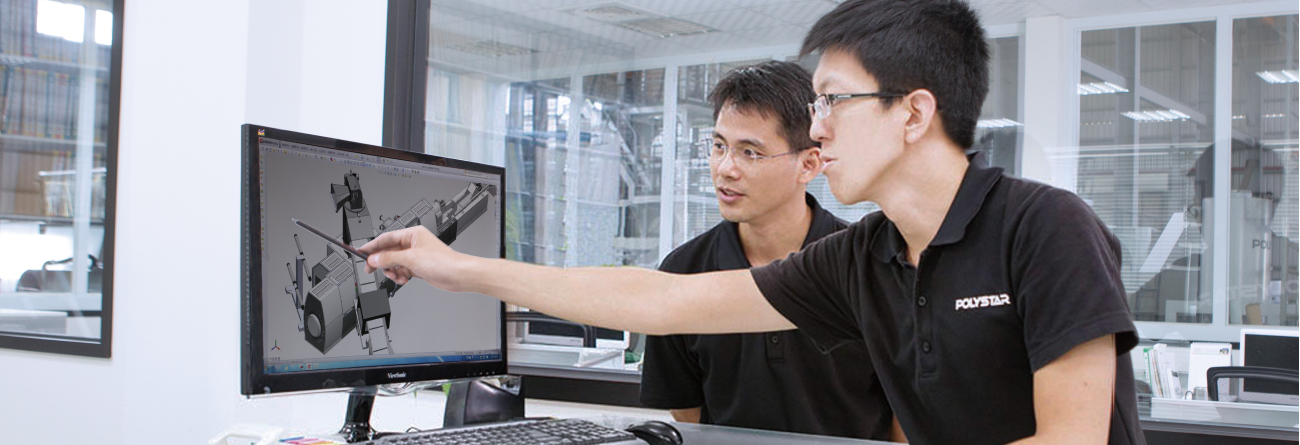

POLYSTAR has been working directly with manufacturers to combine their ideas and requirements with recycling machine design and reengineering to improve overall equipment effectiveness, product quality, and operator control.

Three recycling machines for different plastic materials

As a manufacturer of recycling machines, we must keep in mind that recycling demands more than just a machine. It's critical to have a plastic recycling machine that runs smoothly and produces high-quality products. Producers can choose from a variety of recycling options provided by POLYSTAR. Here are some suggestions to ensure that your recycling process meets your needs and requirements.

1. For factory film waste

Recycling your industrial trash can help you save money on production. The reusability of your pellets will be 100% if your material is 100% from your production, allowing you to reuse them in your factory line.

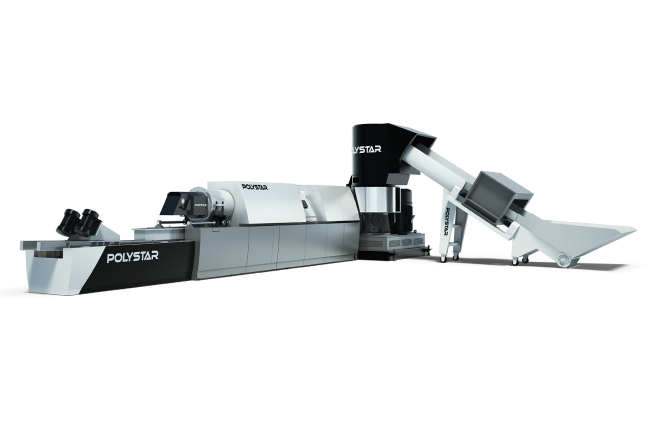

POLYSTAR's Repro-Flex plastic recycling machine is designed to recycle PE (HDPE, LDPE, LLDPE) and PP flexible packaging waste.

This machine has a cutter compactor, which eliminates the requirement for material pre-cutting. The system uses centrifugal force to feed the material directly into the extruder, ensuring that it is in the best possible condition for extrusion.

- Want to know more about this product: Customer Stories - Japanese recycler increases efficiency and production in pelletizing

2. For factory raffia waste

Due to the strength and mechanical qualities of the materials, recycling PP raffia, woven sacks, tapes, non-woven/woven, and bulk bags in one step may be difficult for some producers.

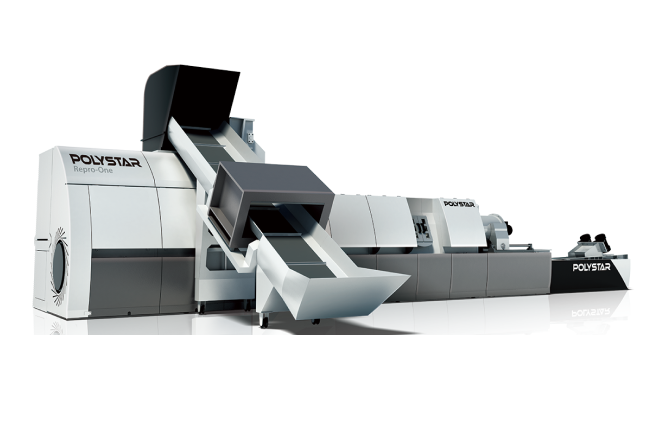

The versatility of POLYSTAR's Repro-One shredder integrated recycling machine allows raffia and non-woven/woven bag producers to quickly reprocess their factory production waste in just one step.

A heavy-duty single-shaft shredder is included in this equipment and is immediately connected to the extruder and pelletizing system. Tapes, fabric, giant bags, lumps, and other PP trash can all be pelletized with this equipment. Recycling pellets can be simply reintroduced into tape extrusion processes.

-

Want to know more about this product: Successful Story - Shredder Integrated Plastic Recycling Machine

3. For multilayer film and post-consumer waste

Multilayer films, heavily printed plastic waste, post-consumer plastic trash (pre-washed and pre-dried), and BOPP films can be recycled; however, reprocessing them is complex. Most of the time, the recycled pellets made from these materials are of poor quality.

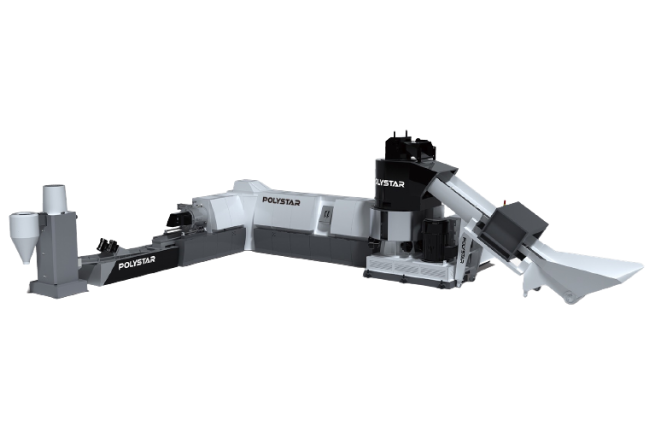

The two-stage recycling machine Repro-Flex Plus from POLYSTAR satisfies your needs if you're searching for little material degradation.

It can reprocess post-consumer plastic waste and highly printed material, and thanks to the integration of the cutter compactor and systems like the two filtrations and three degassing units, your recycled pellets will be of the highest quality and productivity.

- Want to know more about this product: Two-stage Plastic Recycling Machine

Why do we need the factory waste recycling machine?

Producers are looking for solutions to their needs due to a shortage of resins and new trends of utilizing more recycled materials. POLYSTAR provides your factory with exceptional design in your plastic recycling equipment. Providing you with the highest quality recycled pellets, easier machine control, and lower production costs.

About the Author

Maria Lopez

Marketing ManagerMaria Lopez is a content marketer at POLYSTAR. She authors in-depth guides that provide solutions to Plastic Producers. Not only to select your machine but also to keep you updated with the new trends.

__23L13slB6Z.png)