We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Maximizing Your Plastic Recycling Efficiency with Custom Layouts and Optional Devices

How does customization maximize the efficiency of plastic recycling?

Plastic recycling machines that are highly capable of customization can play an important role in the recycling process by providing advantages such as:

- Saving energy and factory space

- Tailored to specific types of plastic waste

- Increased flexibility and eased recycling

- Improved quality of recycled plastic

- Encouraging recycling for a circular economy

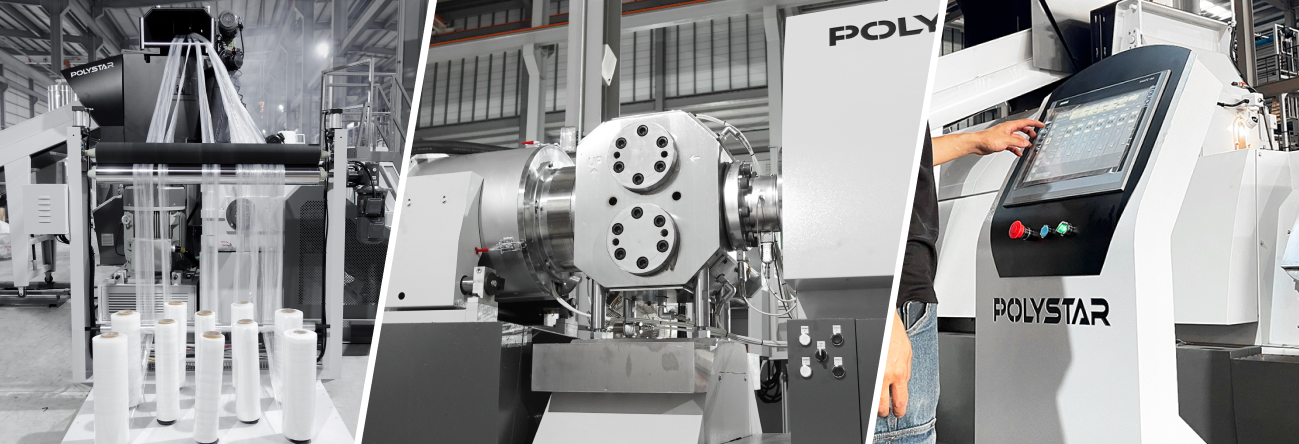

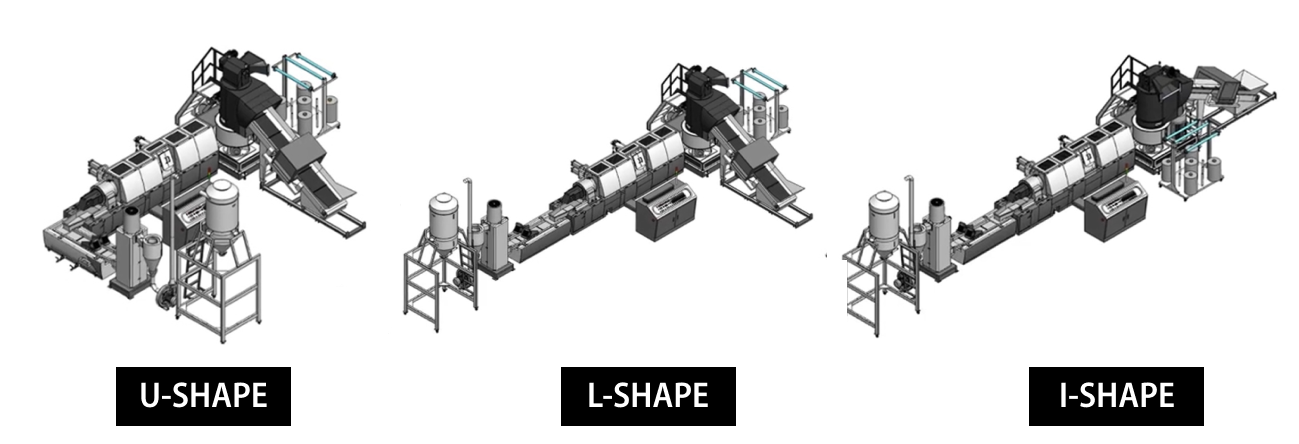

Plastic recycling machine flexible custom layouts

POLYSTAR plastic recycling machine layouts are highly flexible to be customized based on your factory space. All the cutter compactor integrated, shredder integrated, and hopper feeding recycling machine models can be manufactured in L shape, I shape, and U shape layouts. Based on customer requirements, further customization can be provided.

Moreover, considering changing factory space and the operation flow of the customers, POLYSTAR plastic recycling machines are designed for flexible layouts.

* For instance, if you have installed a cutter compactor integrated model Repro-Flex plastic recycling machine with L shape layout, then you want to change it to a U shape, this is possible without adding any extra equipment in most of cases.

- Contact us for further details on machine layout customization.

Plastic recycling machine customization with optional devices

Metal detector

Nip roller

Additive and masterbatches feeder

Allows adding masterbatch, coloring, or additives precisely to enhance the formula and quality of the recycled material.

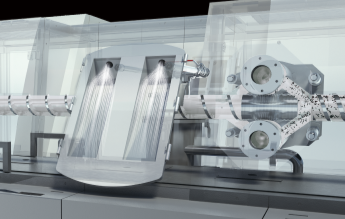

Repositioned filter

The filter before degassing design enhances degassing efficiency, stabilizes extrusion pressure, and increases yield for heavily printed and laminated materials.

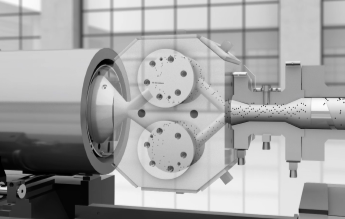

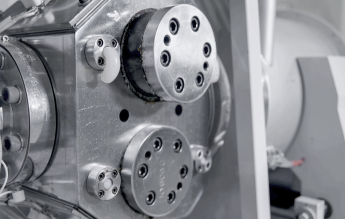

Dual piston screen changer

Automatic back-flush screen changer

The back-flush filter system automatically performs melt waste discharging and reduces the cost of screen mesh replacement as well as saves time.

PLC control System

With a user-friendly HMI, increases recycling automation with features such as automatic pre-heating, parameter optimization, custom parameter memory, online troubleshooting, and so on.

Extra die head for PP/PE

Bi-metallic screw

Improved wear resistance against abrasive post-consumer materials. Extends the lifespan of the screw, and reduces downtime and maintenance costs.

Centrifuge dryer

Provides excellent pellet drying and separation performance. Allows the pellets to be directly used in production just after recycling and saves time.- Contact our sales specialists for further info about optional device customization.

In conclusion, flexible layout and customization of the plastic recycling machines make it possible to adopt versatile plastic recycling requirements with the minimum investment costs, minimum space requirements and minimum interference of the operation flows in the factories. Perhaps, we didn't cover your customization requirement in this article due to limited space. We would be more than happy to talk further about how we can contribute to your plastic recycling business when you contact us on the earliest occasion.

About the Author

Resul Gökpınar

International SalesResul creates up-to-date content based on his experience, gained by solving customers' problems in Turkey and the EMEA market.