We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

How to Start a Recycling Business? A Crucial Preparatory Guide

Introduction

Plastic recycling is a growing industry. There are numerous factors to consider if you want to start a recycling business. You must decide what types of plastics you will recycle, determine the location of your business, research local and state requirements, research your customers, set up accounts with plastic buyers, estimate start-up costs, obtain necessary financing, arrange for plastic transportation, and, most importantly, invest in a reliable plastic recycling machine.

Plastics are a diverse group of materials, and some plastics can be recycled by one type of process, while others require special processing. In order to figure out what types of plastic you will recycle, you first need to understand the different types of plastic that are available.

The most commonly recycled plastics

The most commonly recycled plastics are PET (Polyethylene terephthalate), HDPE (High-density polyethylene), LDPE (Low-density polyethylene), and PP (Polypropylene).

-

PET

PET is a popular plastic for water and soda bottles. It's also often used to make plastic bottles and containers. PET is a clear, tough, and transparent plastic that is resistant to damage and cracking. -

HDPE

It is used to make plastic jugs, containers, and bottles that you might use for milk or juice. -

LDPE

It is used to make plastic films, packaging, and bags. -

PP

It is a versatile, lightweight, strong plastic that can be used in a variety of applications including packaging, containers, and bottles.

How to choose the recycling machine for different plastic materials?

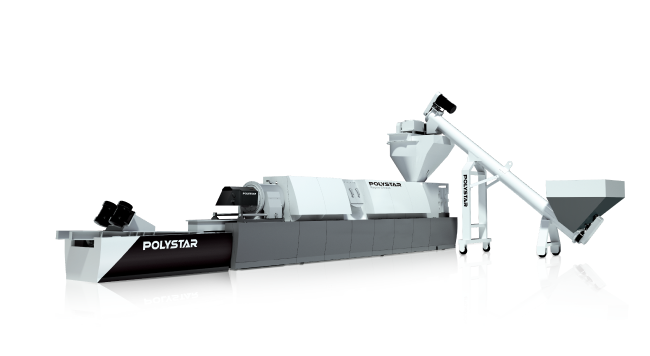

For PET: Repro-PET recycling machine

This model is equipped with a strand-type pelletizing system, it is perfect for reprocessing plastic materials with high fluidity like PET. The air knives on this model make PET pellets with a uniform shape and high reusability rate.

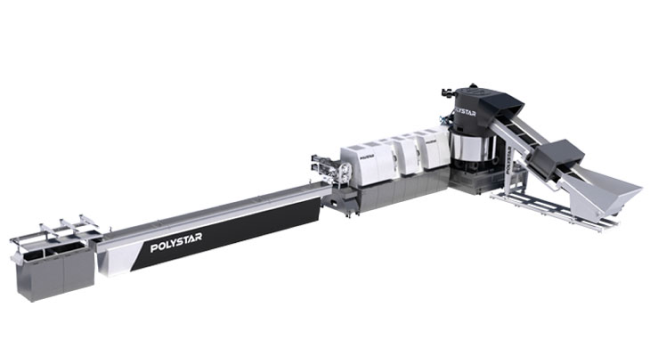

For HDPE, LDPE, PP films: Repro-Flex recycling machine

For HDPE, LDPE, PP films with high printing areas: Repro-Flex Plus recycling machine

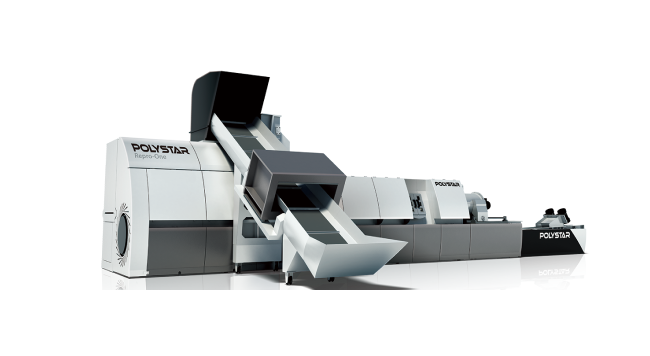

For PP raffia, woven, non-woven: Repro-One recycling machine

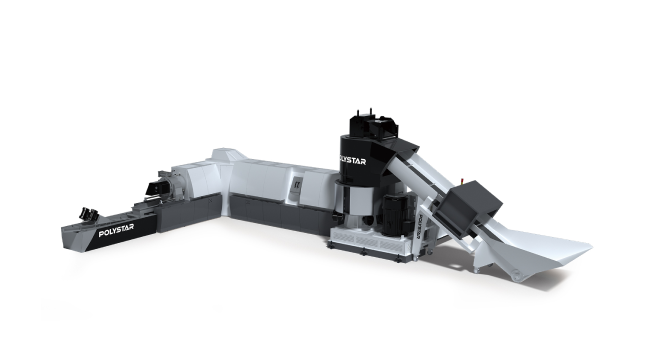

For PE, PP rigid regrinds: Repro-Direct recycling machine

This model does not have a compactor or shredder, you can feed the rigid regrinds directly into this machine through a hopper. This system ensures a faster and easier machine starting and stopping process compared to other plastic recycling systems.

For clean HDPE, LDPE films: Repro-Air recycling machine

This model is an air-cooled mini plastic recycling machine, which does not require huge space and budget for you to start recycling in your factory. It has a simple design that makes it very easy to operate. This mini plastic machine can be placed right next to your blown film machines or bag-making machines for you to recycle the waste right away.

Conclusion

About the Author

Derek Shiao

Derek Shiao is a business development manager at POLYSTAR. He keeps up with the latest trend in the plastic industry and creates content based on his experience offering various solutions to customers.