We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

How to Recycle Woven Polypropylene Feed Bags Efficiently?

Woven polypropylene (PP) feed bags are a common type of packaging material for animal feeds and other agricultural products due to their strong, durable, and lightweight features. These packaging materials are indeed one of the applications of PP woven bags that can be recycled. Recycling post-consumer waste and post-industrial production scraps is an important way to reduce waste, conserve resources, and save various costs.

In this blog, we will mention the process of woven polypropylene feed bags and highlight the appropriate plastic pelletizers that can be used to produce highly reusable recycled PP plastic pellets.

Benefits of Recycling Woven Polypropylene Feed Bags

Recycling woven polypropylene feed bags offers a range of environmental and economic advantages. By properly recycling these bags, we can create a more sustainable future. Let's explore the four key benefits of recycling woven polypropylene feed bags:

- Reduces waste and pollution

- Conserves resources by generating recycled PP plastics

- Saves energy compared to manufacturing virgin polymers

- Creates a circular economy by reusing plastics

How to Convert Woven Feed Bags to Recycled Polypropylene?

(Defected woven polypropylene feed bag production scraps)

1. Post-industrial Production Scraps of Woven Polypropylene Feed Bags

💡 How to Recycle Post-industrial Woven Polypropylene Feed Bag Scraps

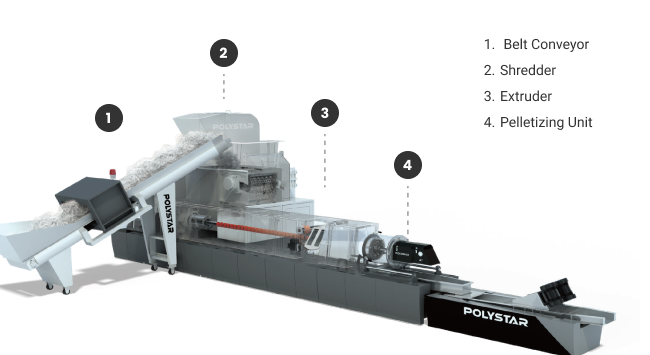

Repro-One Shredder Integrated Plastic Pelletizer combines shredding, extrusion, and pelletizing steps into a single recycling machine. The integrated shredder, on the other hand, works at a low processing temperature to ensure minimal material degradation when recycling woven polypropylene feed bags. The capability of this line to process a variety of unprinted and printed woven polypropylene bags and lumps is approved by many PP raffia and woven bag manufacturers.

- Explore how Repro-One works – Machine Information

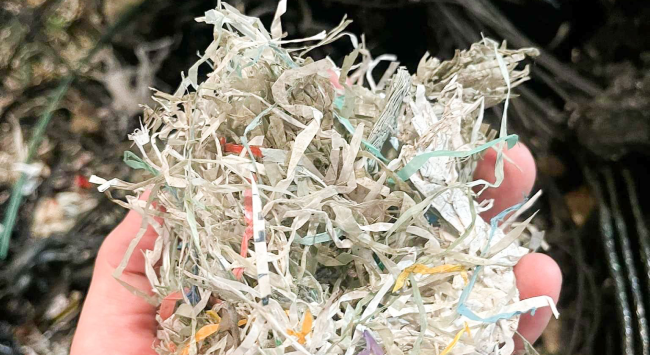

(Crushed and washed woven polypropylene feed bag waste)

2. Post-consumer Waste of Woven Polypropylene Feed Bags

💡 How to Recycle Post-consumer Woven Polypropylene Feed Bag Wastes

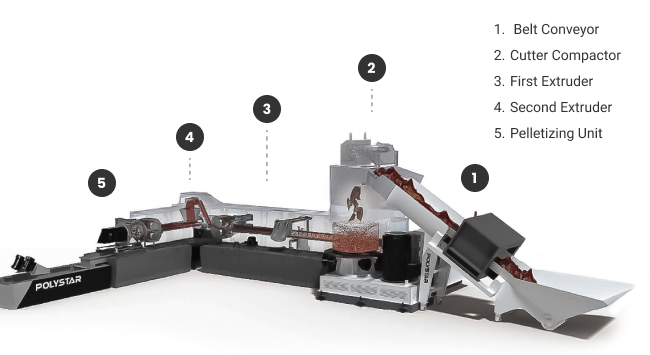

This one-step two-stage pelletizer provides an enhanced triple degassing unit and two filtration unit features along with stable feeding with a cutter compactor integrated, which all together ensures increasing reusability of the recycled polypropylene pellets.

- Explore how Repro-Flex Plus works – Machine Information

Conclusion

In conclusion, recycling woven polypropylene feed bags properly helps to fulfill the recycled PP polymer needs of the industry. Moreover, it promotes sustainability and reduces plastic pollution while conserving resources, energy, and costs. Today contact POLYSTAR to learn more about our woven polypropylene recycling machine solutions.

About the Author

Resul Gökpınar

International SalesResul creates up-to-date content based on his experience, gained by solving customers' problems in Turkey and the EMEA market.