We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

How to Recycle Polypropylene Bags (Woven bags, Bulk bags, etc.)?

"PP bags" is a collective name for a variety of bags made of Polypropylene (PP). Their structure, texture, and properties vary depending on their manufacturing methods, which include single-layer or multi-layer co-extrusion, woven, and non-woven techniques.

- Read more: What is Polypropylene and its applications? - Blog

PP woven bag manufacturing steps

-

Extrusion and Taping

PP virgin resins ( or recycled pellets) along with additives, melt and stretch into flat tapes, which are then cooled and wound into rolls. -

Weaving & Winding

The PP tapes will go through a weaving machine which interweaves the fabric together and then winds it into woven rolls. -

Coating & Printing

Customize PP woven rolls with printed designs or logos. The coating prevents moisture from getting in and contents from leaking out. -

Cutting and Sewing

Cut the bags to the desired size and shape, followed by sewing the sides, and make sure they are strong enough to withstand the weight of the contents.

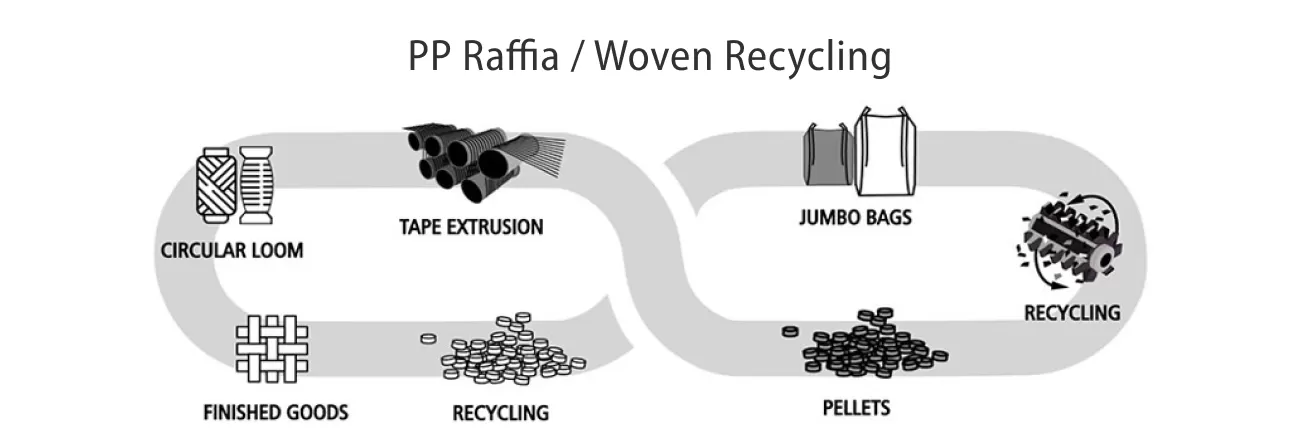

PP woven bag recycling steps

-

Collecting & sorting

Gather PP woven bags from factories or waste programs, and sort out the undesired waste. -

Cutting

Decrease the size of the PP woven bags for enhanced washing and drying convenience. -

Washing & drying

Remove the major impurities and reduce the moisture content to 3~5%. -

Pelletizing

Employ mechanical recycling techniques, including extrusion

Impacts & Benefits

How to reduce the environmental impact of PP woven bag manufacturing?

-

Reusing old PP woven bags

Since woven bags are cost-effective, light in weight, and resistant to tear and humidity, PP woven bags are found in various industries. For instance, they are employed in agriculture for storing items like rice, flour, and seeds, as well as in construction for material and debris storage.

These bags, including sacks or FIBCs, are 100% reusable and recyclable. If there are no significant damages, they can be economically and sustainably reused even after the initial consumption.

-

Recycling PP woven bags

However, if the PP woven bags reach the end of their functional life, they should be collected, recycled, and reprocessed to new PP products. Whether you're a producer or recycler, pelletizing is the most effective way to recycle PP woven bags.

PP woven bag recycling

Recycling here refers to pelletizing PP woven bags, turning both post-industrial and post-consumer PP woven bags into valuable PP recycled pellets. Through mechanical recycling, PP woven bags are able to enter a life circle and the industries strive with sustainability.

Tips (1): For post-consumer PP woven bags, a thorough washing and drying process is essential before proceeding to extrusion and pelletization stages.

Tip (2): When utilizing a Cutter-compactor type plastic recycling machine, it is suggested to pre-crush PP woven bags before the recycling process.

Tip (3): Remove the unwanted elements such as nylon straps or labels that could affect the quality of the final pellets.

Shredder Integrated PP Woven Bag Pelletizer (Post-industrial Waste)

Cutter Compactor Plastic Recycling Machine (Post-industrial Waste)

Two-stage Cutter Compactor Plastic Pelletizer (Heavily-printed & Post-consumer Waste)

Conclusion

Read More

About the Author

Janine Cheng

Marketing AssistantJanine creates engaging content for POLYSTAR’s social media presence, including keeping social media channels updated and brand-focused and seeking ways of connecting with plastic producers and recyclers.