We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

How to Recycle BOPP Films?

What is BOPP film?

The major advantages of BOPP films:

- BOPP films have an excellent gloss and high transparency, giving them an excellent appearance and fine finish.

- Lower electrostatic charge.

- BOPP films perform well in high-speed printing.

- BOPP films are not affected by moisture and do not wrinkle or shrink in response to environmental changes.

- They are recyclable.

What are the most common BOPP films?

Perfect model for plain BOPP film recycling:

Repro-Flex is a cutter compactor recycling machine that is ideal for processing plain BOPP films. This simple but powerful plastic recycling machine combines cutting, extrusion, and pelletizing. The cutter compactor on the recycling machine prepares (pre-conditions) the BOPP film for extrusion and feeds it directly into the extruder using centrifugal force. Unlike traditional plastic recycling machines, this integrated system does not require a separate crusher, eliminating the issue of inconsistent feeding.

Key benefits of Repro-Flex:

- Easy material feeding without the need for pre-cutting.

- Easy operation and maintenance.

- Excellent BOPP pellets can be produced by this model.

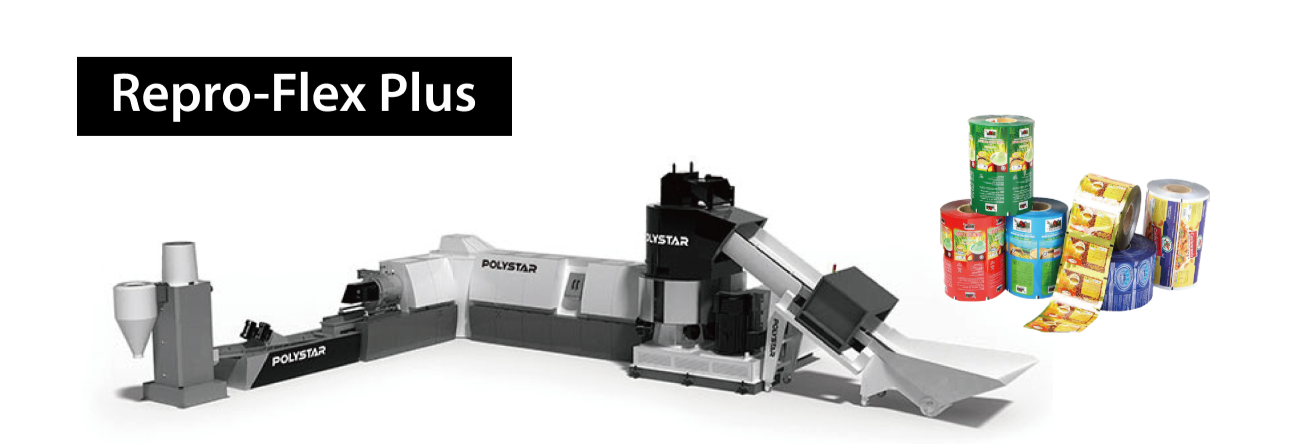

Perfect model for metalized BOPP film with printing

( Printed plastic film recycling machine )

Repro-Flex Plus is integrated with a cutter compactor just like Repro-Flex. This model, on the other hand, has an additional extruder as well as three degassing zones and two filtration units. It is designed specifically for processing heavily printed plastic films, and it ensures the minimal degradation of the material, resulting in uniform pellets that may be reprocessed right into your production line.

( Heavily printed BOPP film )

Filtration before degassing is also a unique design for Repro-Flex Plus. It has a better effect on producing excellent quality plastic pellets from metalized BOPP film with printing. Furthermore, the second extruder features a third degassing system for removing even more ink and moisture from the materials.

With all the features on Repro-Flex Plus, customers can simply achieve 10% less power consumption; 20% higher output; and 100% pellet re-usability using this model to recycle metalized BOPP film with printing.

Key benefits of Repro-Flex:

- Easy material feeding without the need for pre-cutting.

- Easy operation and maintenance.

- Excellent BOPP pellets can be produced by this model.

Conclusion

BOPP plastic film is reusable and recyclable. It can actually be recycled many times while retaining its value. Waste recycling increase revenue while decreasing your company's carbon footprint. With the right machines provided by POLYSTAR, you are able to recycle both plain BOPP film and metalized BOPP film with printing efficiently.

About the Author

Derek Shiao

Derek Shiao is a business development manager at POLYSTAR. He keeps up with the latest trends in the plastic industry and creates content based on his experience offering various solutions to customers.