We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

How to Choose the Right Blown Film Machine for Making Small Plastic Bags?

Choosing the right machine for small film width

POLYSTAR offers different machine types to choose from: Producers can choose between a Mini-type blown film machine (Simple-X) or a Twin head blown film machine (Duo-X).

Both of these extruders can be used to produce small-width plastic film made of HDPE, LDPE, LLDPE, recycled, or biodegradable materials.

Producing film rolls of smaller width can be an easy way for producers who are new in the business to begin their production. Sizes under 800mm are also very common for producers who start to switch their bag production from outsourced into in-house.

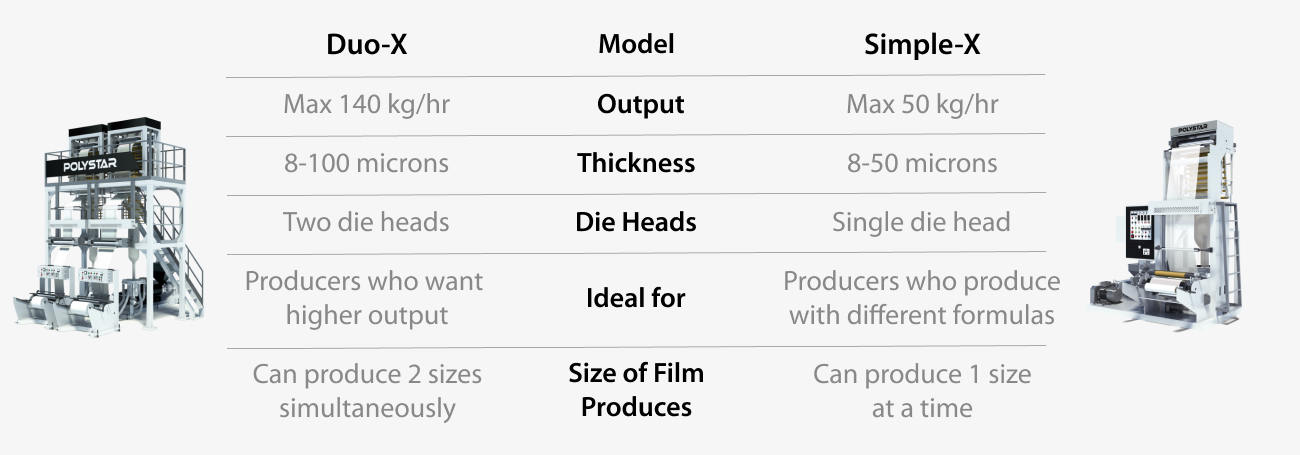

Machine comparison

1. Twin head blown film machine - Duo-X

Duo-X is designed with a single screw that splits the plastic melt into two separate die heads, which is ideal for achieving a higher output in reduced spaces.

Additionally, this machine allows you to produce two separate film rolls of different sizes simultaneously. Which helps avoid lost material and machine downtime when changing the die heads. Moreover, Duo-X saves space in your factory while making it easier for the operator to monitor the machine.

( Changing and monitoring film rolls is easy for the operators )

POLYSTAR’s Duo-X model is highly popular among Vietnamese and Latin American producers, thanks to its high output and space-saving properties.

2. Mini-Type Blown Film Machine – Simple-X

On the other hand, the Simple-X machine is ideal for first-time producers or for producers who have different material or color requirements.

Many producers purchase more than one line given that they are more economical, allowing them to designate one machine for each product. This can help shorten machine downtime while changing the die head and avoid losing material when switching sizes, colors, or formulas.

Comparison: Manufacturing < 800mm Film Roll

If you are interested in learning more about these blown film machines, contact POLYSTAR, our sales team will be happy to assist you.

Learn more

About the Author

Renee Castro

Renee is helping plastic producers find simple solutions to their problems. She is interested in topics like the circular economy and the latest recycling trends.