We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Exploring Different Industries and Product Uses for Plastic Films

Plastic films are versatile, lightweight, and flexible, making them suitable for a wide range of applications. They can be processed and transformed into various products to meet different consumer needs.

Notably, plastic films excel as barriers, effectively protecting items from potential damage. Their affordability, accessibility, and convenience further enhance our daily life.

In this blog, let’s explore the widespread usage of PE film products across different industries. Furthermore, we will provide a machine guideline for your reference if you would like to produce these popular plastic film products.

Commonly seen PE plastic film applications in different industries

1. Retail Industry

Heavy-duty supermarket bags, flat shopping bags, vegetable and fruit bags, gusseted T-shirt bags

( Plastic bags: plastic grocery bags and fruit bags )

2. Household

Zipper bags, cooking bags, garbage bags, disposable plastic tablecloths, disposable gloves

Household plastic film applications provide convenient solutions for storage and cleaning tasks. Zipper bags are often preferred over glass containers to save time on cleaning when storing or marinating food. Similarly, disposable tablecloths and gloves offer a practical way to minimize the need for extensive cleaning.

( Household plastics: zipper bags and disposable plastic gloves )

3. Food and Beverage Industry

Heat-resistance bags, cup-sealing film, bread bags, self-sealing cookie bags

Plastic bags act as reliable barriers, protecting food and beverages from potential pollutants while preventing spills and leaks. Additionally, their flexibility makes them suitable for both solid and fluid food items.

( Food packaging: street food plastic bags and bread bags )

4. Logistics and Shipping

Courier bags, air cushions, bubble film, protective covers

For shipping purposes, plastic films and bags are to prevent items from exposing and falling apart during transportation. Moreover, applications like air cushions and bubble films offer an additional layer of impact absorption, minimizing the risk of damage during transit.

( Shipping packaging: bubble wrap and courier plastic bags )

5. Pharmaceutical and Medical Industry

Medical waste bags, specimen bags, drug bags, disposable aprons

Plastic films and bags play a crucial role due to their exceptional barrier properties. They serve purposes such as storing hazardous waste, preventing cross-infection, and maintaining the cleanliness of medical items for invasive procedures.

( Medical plastics: specimen bags and disposable aprons )

What qualities make high-quality plastic films?

-

Strength and durability

Bear demanding weight or impact without tearing

-

Moisture, heat, and oxygen barrier

Preserve the integrity and freshness of the item

-

Flexibility

Conform to different shapes of the item, ensuring efficient packaging

-

Heat sealability

Ensure secure closure and protection by good heat-sealed performance

-

Printability

Allow for high-quality printing, boosting branding, and information display

-

Sustainability

Reduce the impact on the environment, such as using eco-friendly materials

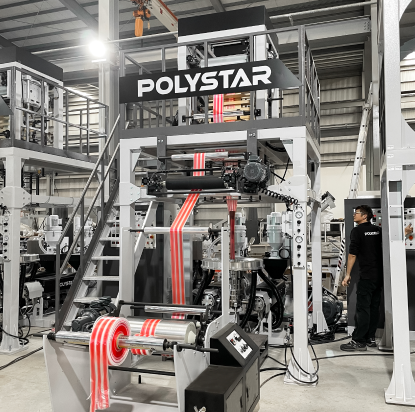

Blown film machines for diverse applications

Solutions for producing Polyethylene plastic films – HDPE, LDPE, LLDPE

POLYSTAR offers diverse solutions for different end products. For instance, Twin-head blown film machines and Mini-blown film machines are ideal for producing narrow film widths, suitable for applications like fruit bags, zipper bags, and drug bags.

For larger plastic film products such as garbage bags, pallet covers, and tablecloths, our Standard film machines provide wider plastic films to meet your requirements.

Highly automated and user-friendly blown film machines enable you to produce high-quality plastic films with the desired key qualities. Additionally, we offer customization options and optional devices to meet your specific requirements.

Last but not least, our special screw design allows for the incorporation of recycled materials, CaCO3, and biodegradable materials, providing both financial and environmental benefits.

If you are interested in producing plastic films, contact us right now.

About the Author

Janine Cheng

Marketing AssistantJanine creates engaging content for POLYSTAR’s social media presence, including keeping social media channels updated and brand-focused and seeking ways of connecting with plastic producers and recyclers.