We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Exploring the Blown Film Extrusion Process for Plastic Bags

Have you ever wondered how the plastic bags you use in your daily life are made? In this blog, you will find everything you need to know about plastic bag production through the blown film extrusion process.

The Blown Film Extrusion Process

Plastic films are commonly made through a process called blown film extrusion, which is a widely used method for producing the films used for making bags. The blown film extrusion process is efficient and versatile, allowing manufacturers to create a variety of film thicknesses and properties. Here is a general overview of the process:

Polymer Selection

Extrusion

Bubble Formation

Cooling and Flattening

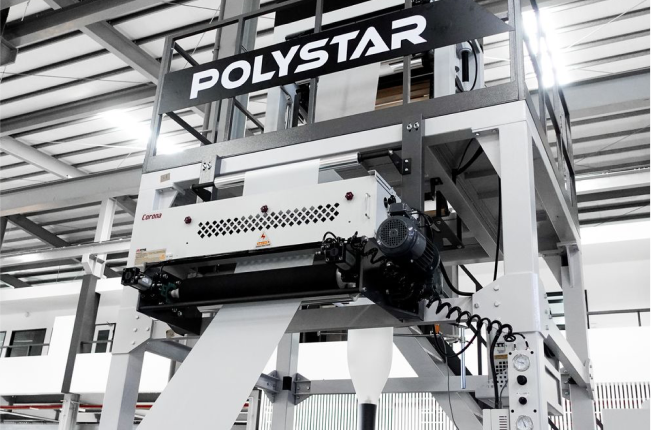

Corona Treatment

Slitting and Cutting

The flattened plastic sheet can be slit into multiple layers if needed. For general bottom sealing bags, slitting isn't necessary, but it is required for shrink film or water sachet. You can also cut the film into smaller sizes during this process to increase efficiency. For example, if you require a 300mm width for the film, you can extrude up to 900mm and then cut it into three pieces of 300mm film to increase the efficiency.

Winding

After flattening, the plastic film is wound onto a winder to form rolls. Automatic winders cut and replace rolls automatically, while manual winders require manual intervention. An automatic winder is ideal if labor costs are high.

Printing (Optional)

Some manufacturers add printing to the film before bag production. This involves feeding the film through a printing machine that applies logos, designs, or information. Ink choice and printing technique depend on the desired visual impact and film type.

The above steps outline the blown film extrusion process, resulting in a film roll. This roll can be used to make plastic bags with another machine or sold to plastic bag manufacturers.

If you are interested in POLYSTAR's blown film extrusion machines, please provide the following details:

- Your intended material: LDPE or HDPE?

- Maximum desired film width.

- Desired hourly output capacity.

- Whether you require any printing capabilities.

We will provide a quotation based on your information to help you start your business.

From Blown Film Extrusion to Finished Plastic Bags

With the film roll produced by the blown film extrusion process, we can now move on to the bag making process. Here's how the film extrusion output becomes the plastic bags we use daily:

Bag Cutting

The film roll, a product of the blown film extrusion process, unwinds and enters a specialized bag-making machine. Sharp blades precisely cut the film into individual bag shapes based on pre-programmed dimensions. This determines the size and style of the final bag (like t-shirt handles). Various cutting and sealing methods exist on different bag-making machines, with some offering folding functionality. Consult your bag-making machine supplier to ensure the equipment meets your specific requirements.

Counting and Stacking

The finished bags, now transformed from the blown film extrusion output, are counted and stacked by the machine, ready for packaging or further processing. Automatic stackers ensure organized and efficient handling.

Manual Packaging

Depending on the customer's needs, the bags can be bundled, packed into boxes, or placed on pallets for storage or distribution. This ensures safe and organized transportation of the final product from the film extrusion process.

Quality Control

Throughout the blown film extrusion to bag making process, quality control checks are performed to ensure the bags meet size, strength, and printing specifications. This involves visual inspection and sometimes machine-based testing.

Conclusion

That's the transformation journey from blown film extrusion to finished plastic bag! Remember, this is a general overview, and specific steps or equipment might vary depending on the bag type, desired features, and production scale.

Plastic bags will likely remain a part of our lives for the foreseeable future. However, with companies like POLYSTAR leading the way, the future of plastic bag production is moving towards sustainability, innovation, and responsible manufacturing practices in both blown film extrusion and bag-making processes.

Again, if you are interested in POLYSTAR's bag-making machines to complement your blown film extrusion line, please provide the following details:

1. The type of plastic bags you intend to produce.

2. The dimensions of the plastic bags you are planning to produce.

Want to Learn More?

Visit POLYSTAR's website to explore our wide range of machines for blown film extrusion and bag making, our commitment to sustainability, and the latest innovations. You can also find insightful videos on our YouTube channel showcasing our machinery and production processes. For personalized assistance and to discuss your specific needs in fil extrusion and bag making, feel free to reach out to us via email at sales@polystarco.com. We look forward to the opportunity to assist you in optimizing your plastic bag production line.

About the Author

Derek Shiao

Derek Shiao is a business development manager at POLYSTAR. He keeps up with the latest trend in the plastic industry and creates content based on his experience offering various solutions to customers.