We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Comparison of Screen Changers for Recycling Machines

Dual Piston Type VS Slide Type with Pressure Accumulator

Filtration in plastic recycling is one of the essential steps. Whether the plastics being processed are post-consumer materials or in-house materials from plastic production, they must pass through a filtration step during the recycling. Recycle plastics require different types of filtration systems depending on their condition and contamination level. The filtration systems are generally called screen changers in plastic recycling.

In this article, we will provide a brief comparison between the Hydraulic dual piston screen changer and the hydraulic slide-type screen changer with pressure accumulator.

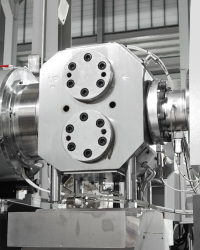

1. Hydraulic dual piston screen changer

2. Hydraulic slide-type screen changer with pressure accumulator

__24D11FZxfv.png)

Technically, the slide-type screen changers are well known since being used for a long time in recycling. Especially the recyclers who process post-consumer materials which require frequent change of filter mesh, would prefer this type of screen changer. However, the slower motion of the filter block would cause slower movement of the filter blocks, resulting in a longer time to change the filter mesh and more material loss. The hydraulic slide-type screen changer with pressure accumulator comes to aid with faster filter block movement to solve these problems.

Faster filter block movement with the pressure accumulator

The hydraulic slide-type screen changer is equipped with a pressure accumulator that helps the filter blocks move faster. It is a suitable solution for slightly dirtier material that requires frequent screen changing. The system operates similarly to the classic slide-type filter, yet provides superior advantages including:

- Fast filter-block movement to reduce the time needed for screen changing

- Minimum material loss during screen changing

- The filter mesh is faster to change compared to the piston-type screen changer

- More similar to the traditional slide type screen changers that operators are familiar with

Comparison: Which screen changer is more suitable for you?

Dual Piston Screen Changer |

Slide Type Screen Changer with Pressure Accumulator  |

|

| Operation | Hydraulic, semi-automatic | Hydraulic, semi-automatic |

| Meshing changing duration | Longer | Shorter |

| Material loss | Minimal | Minimal |

| Labor Intervention | Less | More |

Conclusion

Even though both dual piston screen changers and slide-type screen changers with pressure accumulator systems can be used for filtration of the same materials, one provides different features from the other for the specific requirements and operator’s preferences. Making a quick judgment between these two screen changers without including your materials will not be accurate. The first step must be to consider your materials' contamination level before feeding them to the recycling extruder and your labor force. Briefly, we suggest:

-

The dual-piston type screen changer would be the better solution for in-house plastic production wastes and cleanly washed and dried post-consumer plastic wastes. Since the material is non to less contaminated, the mesh changing frequency will be less, thus the labor intervention.

-

The slide-type screen changer with pressure accumulator can be an optional solution for slightly dirty materials, which are not dirty enough to utilize the washing line, but dirty enough to clog the filter mesh faster and require frequent labor intervention to change it. This screen changer could be also considered for post-consumer materials that still have contamination after washing.

About the Author

Resul Gökpınar

International SalesResul creates up-to-date content based on his experience, gained by solving customers' problems in Turkey and the EMEA market.