We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Comparison of Pelletizers for PE/PP Plastics - Which Plastic Recycling Machine can Fit Your Demands?

Different plastic materials have their unique properties and are manufactured to become many kinds of products that apply to our daily lives, which can be divided into several categories. For instance, plastic films, food packaging, flexible plastic packaging, medical device components, and so many others…

Typical plastic applications in our daily lives

Hard plastics are mainly used to produce PP containers, PP medical components, HDPE water bottles, Plastic Toys (ABS), and Packing material (PS), these kinds of materials are also well-known for their strong and stiff characteristics, with these advantages, rigid plastics have been applicated around the world.

Another type is plastic film, which is used in a variety of applications, including: supermarket bags, zip-loc bags, packaging film, or building construction film. With the increasing amount of plastic film, many producers recognize the potential profits of reclaiming and reusing this particular type of plastic waste.

How to identify a pelletizer that is right for your recycling business?

Before starting a recycling business, finding the perfect plastic pelletizer that fits the production line and the market demand is very important. So, which plastic pelletizer will be able to accommodate the needs of your plastic recycling project? Here are two machine recommendations for you:

1. Pelletizer for PE, PP, ABS, PS hard plastic recycling

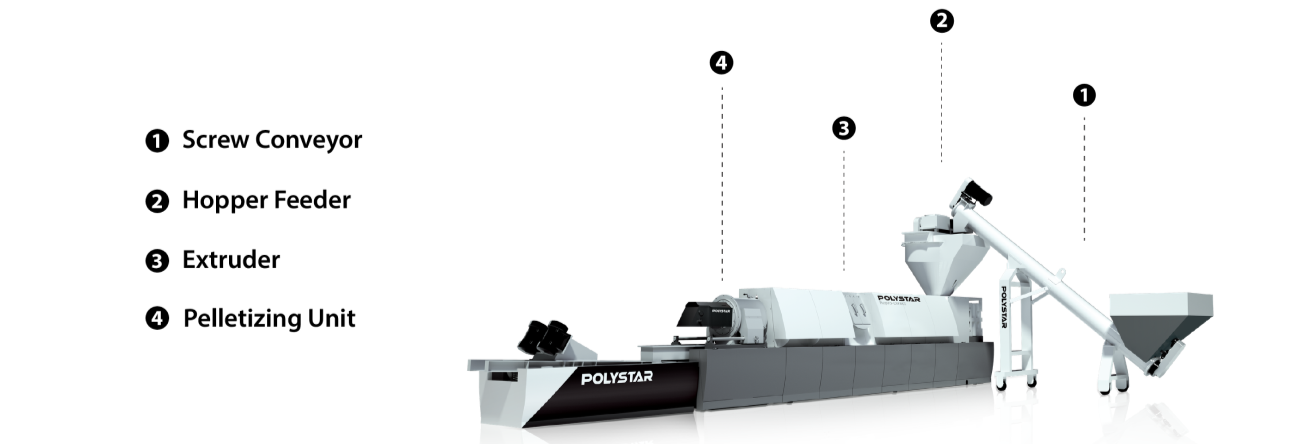

For the recycler who wants to reprocess the PE, PP, ABS, or PS hard plastic, Repro-Direct is the most recommended plastic pelletizer, this machine uses a screw feeder to convey and can directly feed the plastic regrind into the extruder that requires less power but is more efficient.

How Repro-Direct hard plastics pelletizer works:

When producers want to process PE, PP, and ABS rigid plastic, the first step is pre-crush the materials before feeding them into the screw feeder, then the screw starts to rotate and convey the plastic regrind into the hopper (step 1 -> 2 in the picture), the force feeder may be added on to further prevent the effects of bridging. After plastics being melted in the extruder, it will transfer to the pelletizing unit and start to make plastic granules.

2. Pelletizer for PE, PP Film plastic recycling

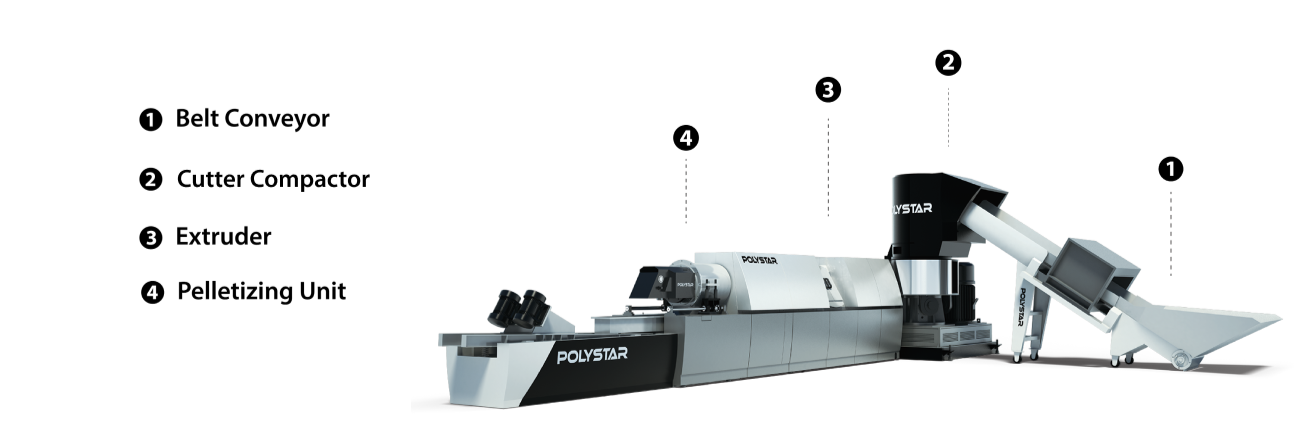

Repro-Flex is the ideal machine for recycling PE and PP plastic film, plastic producers can place this machine next to their production line to process the industrial waste, in order to directly put the recycled plastic back into the production line.

How Repro-Flex plastic film pelletizer works:

When processing PE and PP plastic film, the recyclers can choose to feed the film by using a belt conveyor, a nip-roller, or both at once, with concurrent feeding and speed control (the sensor will detect the quantity of the plastic waste and feed the materials), which means the labor costs can be reduced.

As long as the belt conveyor/nip-roller feeds the plastic films into the cutter-compactor (step 1 -> 2 in the picture), it starts to cut and compact the plastic waste into small pieces, then transfer the waste to the extruder for melting, then start granules making in the pelletizing unit.

The differences between the two types of PE/PP pelletizers

|

Repro-Flex

|

Repro-Direct

|

|

| Machine Cost. | PE/PP Plastic film, plastic scraps, industrial plastic waste… | Screw feeder/Conveyor belt |

| Feeding Type | Conveyor belt/ Nip-roller | LowerMore recycled material or CaCO3 can be used for film production |

| Hopper | No | Yes |

| Force Feeder | No | Yes (Perfect combination with the hopper) |

| Cutting integration | Cutter compactor | None |

( Simple graph for Repro-Flex and Repro-Direct machine comparison )

In Brief, the differences between Repro-Flex and Repro-Direct are:

-

The main process materials:

Repro-Direct can process hard plastic wastes (pre-crushed), and Repro-Flex is suitable for processing flexible plastic films and film rolls. -

Feeding type:

Both plastic pelletizers can adopt a belt conveyor for feeding, however, Repro-Direct can change to a specific screw feeder for processing plastic regrind, while Repro-Flex has a nip-roller for feeding plastic film. -

Using hopper/force feeder or not:

Compared to flexible plastic film (needs cut and compact), recycled hard plastic regrind can be put directly into the extruder by the hopper as it has already been crushed, moreover, the force feeder can add on to prevent the bridging effect. -

Cutting type:

Different from the plastic film recycling machine, the hard plastic machine doesn’t need the cutter compactor to reduce the size of the plastic waste.

About the Author

Sandy Kuo

E-Marketing SpecialistSandy follows up on the market demand and analysis data in the plastic industry, promoting the brand and doing digital marketing activities by e-commerce.