We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

Common Uses for 1-Layer Blown Film Machines in the Plastic Industry

One-layer blown film machines have become a crucial part of the plastic industry. Film produced with these machines is a versatile and cost-effective solution for applications from food packaging to bags of different types. These 1-layer extruders can produce monolayer films of various thicknesses, widths, colors, and materials.

Given the latest trends in recycling, using one layer of plastic film for your products is a great way to incentivize demand for your product by making your plastic products more eco-friendly given that this film is easily recyclable, more energy-efficient and lightweight compared to multilayer film, making it an excellent choice for different applications.

Here, we will discuss the most common uses of one-layer blown film machines and the advantages of using each type for different applications.

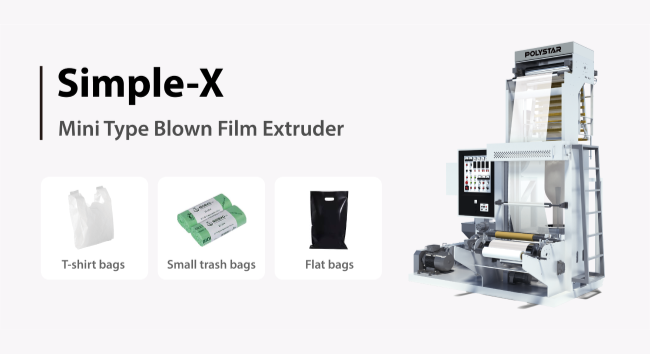

Mini type blown film extruder – Simple-X

- T-shirt bags

- Flat bags

- Food packaging films

- Bags on roll

- Folded bags

- Small trash bags

- Small Medical bags

- Vegetable bags

- Fish transporting bags

- Shopping bags

- Others

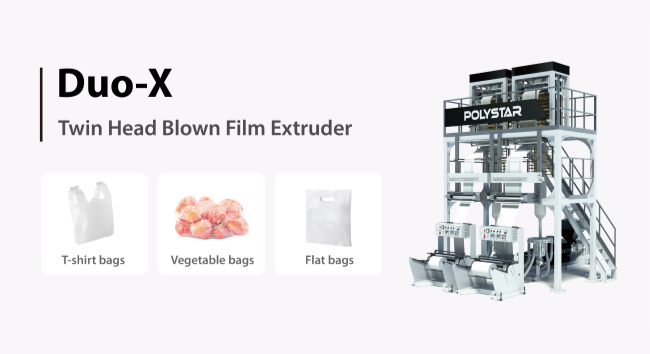

Twin head blown film extruder – Duo-X

Some of the most common product applications for this machine are:

- T-shirt bags

- Flat bags

- Food packaging films

- Bags on roll

- Folded bags

- Small trash bags

- Small Medical bags

- Vegetable bags

- Fish transporting bags

- Shopping bags

- Others

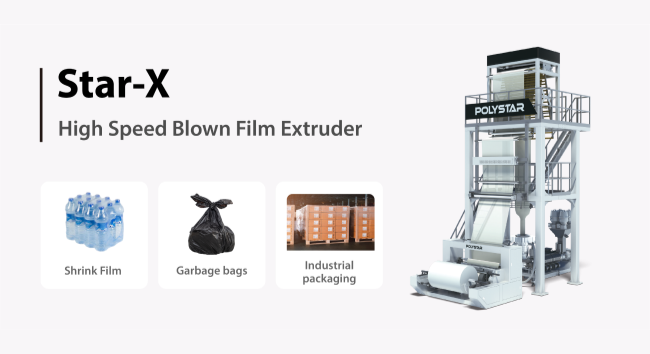

High speed blown film extruder – Star-X

Some of the most common film/bag applications for this machine are:

- Garbage bags

- Food packaging

- Sufra film ( table cover )

- Shrink Film

- Liner bags

- Industrial packaging

- Others

All of these machines’ screw design is suitable for HDPE, LDPE, LLDPE, recycled plastic pellets, CaCO3, and biodegradable materials.

One-layer blown film machines are an essential component of the plastic industry, and their versatility makes them ideal for a wide range of applications. Whether you need a small or large output, one or different width rolls production simultaneously, there is a blown film extruder that can meet your specific requirements.

Learn more

About the Author

Renee Castro

Renee is helping plastic producers find simple solutions to their problems. She is interested in topics like the circular economy and the latest recycling trends.