We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

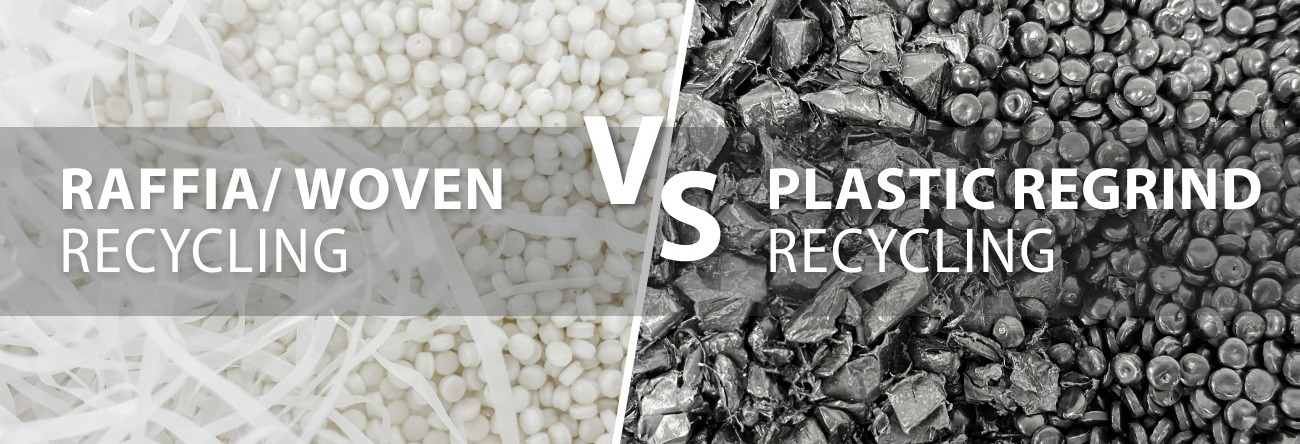

Choosing the Right Recycling Machine: PP Raffia/Woven VS Hard Plastic Regrind Recycling

Which plastic recycling machine is good for you?

One of the most important factors while choosing the right recycling machine for your business is the material itself (type, shape, condition). Recyclers and plastic producers might need to process different types of materials. In this case, focusing on the main material type in your selection can be the most efficient way.-

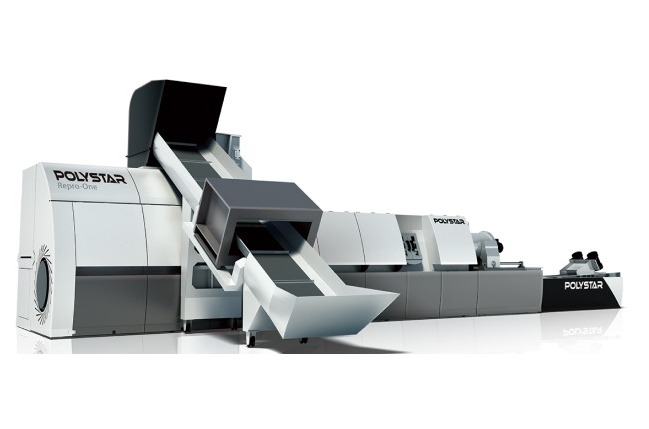

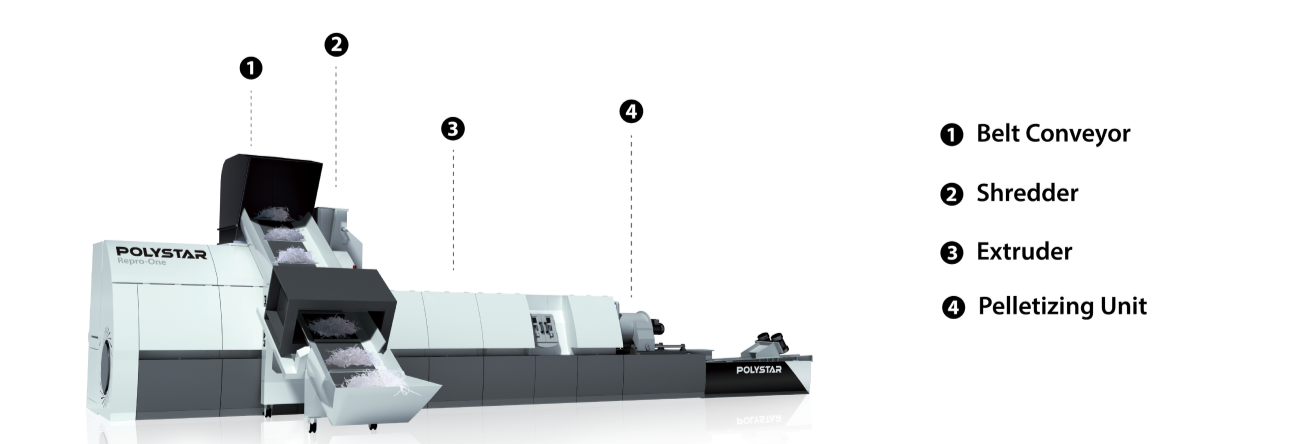

( Raffia/Woven pelletizer )

( Raffia/Woven pelletizer ) -

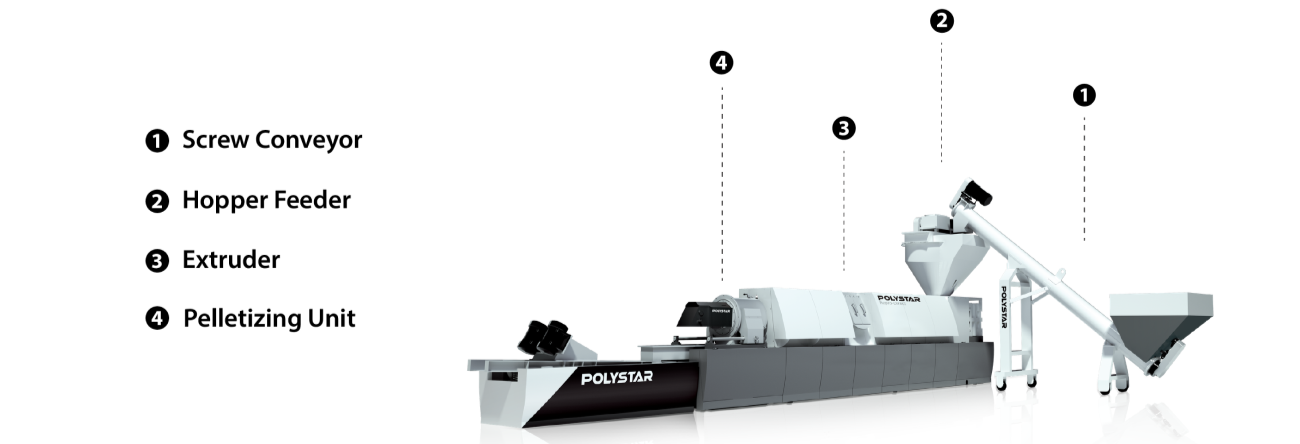

( Plastic regrind pelletizer )

( Plastic regrind pelletizer )

1. Shredder integrated plastic recycling machine for raffia/woven

Many plastic materials must be eventually crushed before feeding to the recycling extruder. In the classical method, this process can be done separately before the extrusion process and the material is stored, then extrusion and pelletizing steps can take place in another process.

This method requires longer time and more labor effort. Also, you will need more space in your factory to place the separated shredder and store the crushed materials. Therefore, this is considered less efficient if you process clean in-house materials (industrial plastic wastes).

Repro-One is designed as a solution for this problem. Single shaft shredder integration makes this machine a time, labor, effort, and space saver for processing PP raffia, woven bags, un-crushed clean big-sized plastics, lumps, and many different materials. Because the recycling system combines shredding, extrusion, and pelletizing processes end-to-end in one step.

2. Hard plastic regrind recycling machine for PE, PP, ABS, PS, PC, PU

Plastic recyclers and producers might have their hard plastic materials or soft packaging materials in pre-crushed form (E.g., washed and dried materials). For these kinds of materials, a plastic recycling machine that provides a fast and direct recycling process would be more efficient.

Repro-Direct is especially the favorite plastic recycling machine of regrind recyclers and injection molding manufacturers. Besides pre-crushed hard plastic regrinds of PE, PP, ABS, PS, PC, and PU; this plastic pelletizer is also more efficient for processing washed and dried flakes from packaging materials such as film, raffia, and foam.

Because, for these kinds of materials, Repro-Direct has the advantage of less power requirement, and provides a faster and easier machine starting/stopping process. Materials can be fed into the hopper directly via screw conveyor without the need for pre-heating before extrusion, and the feeding speed is optimized automatically to achieve the uniform size and shape of pellets.

Differences between PP raffia/woven & hard plastic regrind recycling machines

While the extruders and the pelletizing units of these two different plastic recycling machines can be customized in similar ways, The main differences come in the material feeding and preparation for the extrusion process.

| Repro-One | Repro-Direct | |

| Material Type | PE, HDPE, LDPE, LLDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, EPS |

PE, HDPE, LDPE, LLDPE, PP, BOPP, PA, PC, PS, PU, EPS, ABS |

| Material Shape |

|

|

| Feeding Type | Belt conveyor |

Screw feeder/ Belt conveyor |

| Hopper | No | Yes |

| Force Feeder | No |

Yes (Perfect combination with the hopper) |

| Cutting integration |

Single shaft shredder | No |

( A quick comparison table of Repro-One and Repro-Direct plastic pelletizers )

Learn more

About the Author

Resul Gökpınar

International SalesResul creates up-to-date content based on his experience, gained by solving customers' problems in Turkey and the EMEA market.