We use cookies and other tracking technologies to improve your browsing experience on our website, By clicking "Accept All," you agree to allow cookies to be placed to enhance your browsing experience on this website to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from. You can manage your cookie settings below. Clicking "Confirm" indicates your agreement to adopt the current settings.

3 Benefits You Must Know About In-house Plastic Recycling

1. Why in-house recycling instead of outsourced recycling?

Better quality control changes everything

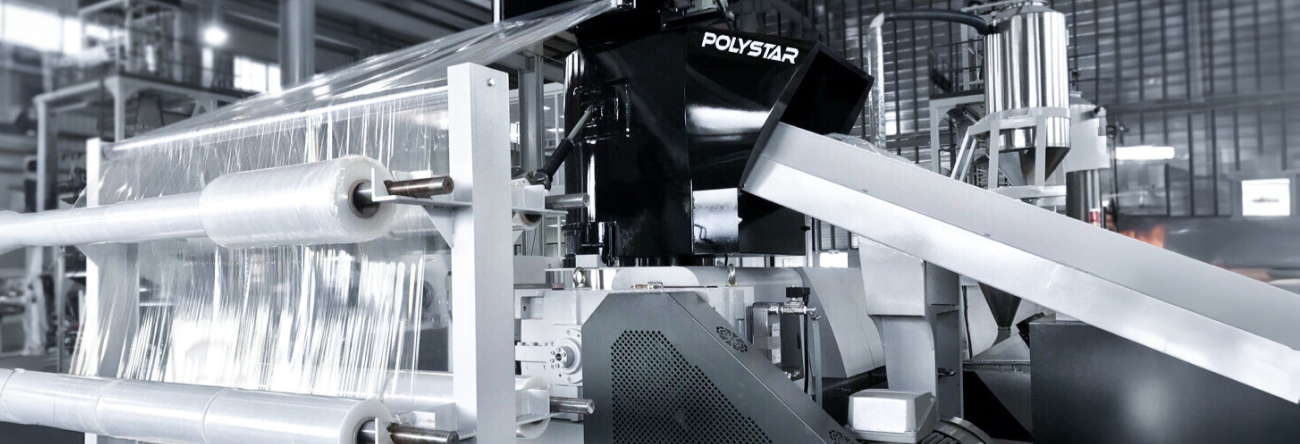

In-house plastic recycling makes sure that the material comes 100% from your production and does not mix with material from other sources. Examples of the in-house scraps are HDPE/LDPE edge trim, cut/punch waste from bag-making production, defected film-on-rolls, start-up film scraps, loose leftover film, HDPE, LDPE/LLDPE, stretch film, shrink film, BOPP, and many others.

Minimal material degradation, pellet quality (size), and consistency can also be achieved and controlled.

Maximum possible amount of recycled pellets

The consistency in quality (uniform in size and minimal property change) of the plastic recycled pellets can ensure that the recycled material can be reused again in the extrusion machines to produce high-end film products with the highest possible quality.

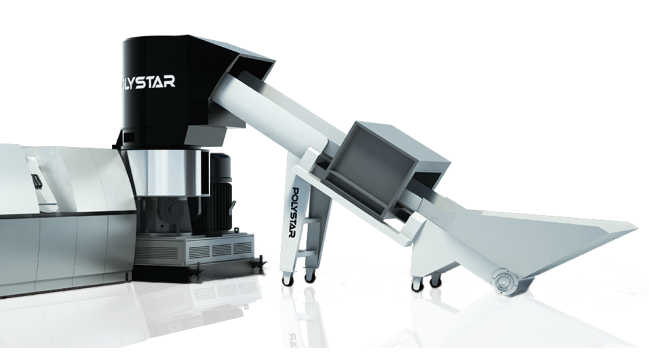

Fast ROI (Return On Investment) on the machine investment

The return on machine investment can be extremely fast, mainly because of the huge savings in raw material costs. When done properly, the quality and reusability of the plastic recycled pellets can be much higher compared to out-sourcing. The extremely simple-to-use machine design requires only one operator at the feeding section of the plastic granulator machine and requires minimal labor intervention.

2. What level of technology is required for efficient in-house plastic recycling?

To process in-house, post-industrial clean scraps, you probably won’t need the most advanced plastic recycling machine in the world to do the simple job – investing in a machine with the highest possible output and most advanced filter systems is unnecessary for most plastic film producers, as recycling is not the main business for them.

However, it is extremely important to have a machine with stable in operation and consistent in pellet quality. This is to ensure that the operation is smooth without quality issues or frequent machine breakdowns. Additionally, it should not be something too complicated for the operators to learn.

3. How Simple are maintenance and operation

Simplicity throughout the entire machine design - From the user interface, machine operation, and maintenance (both mechanical and electrical), to changing consumable spare parts. Even untrained operators can understand how to get the most out of our machines.

Clean and simple process.

Becomes part of your production process.

In-house plastic recycling can be done beautifully with a compact and well-designed plastic pelletizing machine without making the place wet and dirty.

Stable Production

Besides a strong and quality mechanical machine, our recycling machines are powered by world-class electrical components (Siemens, Fuji, Schneider, and Omron) to ensure operational stability.

Electrical breakdown has been a common problem for some producers, and therefore we equip our machines with the best available components for a smooth, 24-hour operation.

Recycling Made Simple -

For 33 years on and looking forward

Over the past 33 years, more than thousands of POLYSTAR plastic recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high-quality pellets in a simple and easy way.

POLYSTAR provides different recycling solutions (different in production capacity and different shredding and cutting integrated technologies) for packaging film (blown and cast), raffia, injection-molded, woven/non-woven, pipe extrusion, and thermoforming. Depending on the user’s material type, industry, capacity requirement, and space limitation, POLYSTAR is able to offer a suitable recycling solution.

Simple Operation

Learn more

- If you are interested in POLYSTAR's successful projects worldwide.

- Check to find the right solution for recycling plastic materials in your factory

About the Author

Jack Lin

Sales ManagerJack has visited and spoken to hundreds of POLYSTAR machine users around the world over the last 10 years. Having collected practical information on customer feedback and user experiences, he enjoys sharing the advantages and disadvantages of using different types of machines with others, especially coming from the customers' perspectives.